Long-fiber reinforced thermoplastic composite material of longitude and latitude glass fiber surface, and molding method and application thereof

A technology for strengthening thermoplastic and thermoplastic materials, which is applied in the field of long fiber reinforced thermoplastic composite materials, can solve the problems of reduced mechanical properties and impact resistance of press-molded products, and achieve the effect of improving order and improving mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Best practice:

[0027] Such as figure 1 , the warp and weft glass fiber surface layer long fiber reinforced thermoplastic composite material, including a matrix 1 and a surface layer 2, the matrix 1 is a long fiber reinforced thermoplastic composite material, and the surface layer 2 is a glass fiber mat surface layer with glass fibers distributed in warp and weft, The glass fiber is impregnated and wrapped with a thermoplastic material compatible with the matrix material, and the surface layer in a molten state after heating is molded with the matrix material in a molten state to be cross-linked into one body.

[0028] In this way, the glass fiber mat with warp and weft distribution of the surface layer and the LFT-D matrix form an organic whole, which improves the mechanical properties of the long fiber reinforced thermoplastic composite. Compatible thermoplastic materials ensure the compatibility of the substrate and surface layer bonding interface.

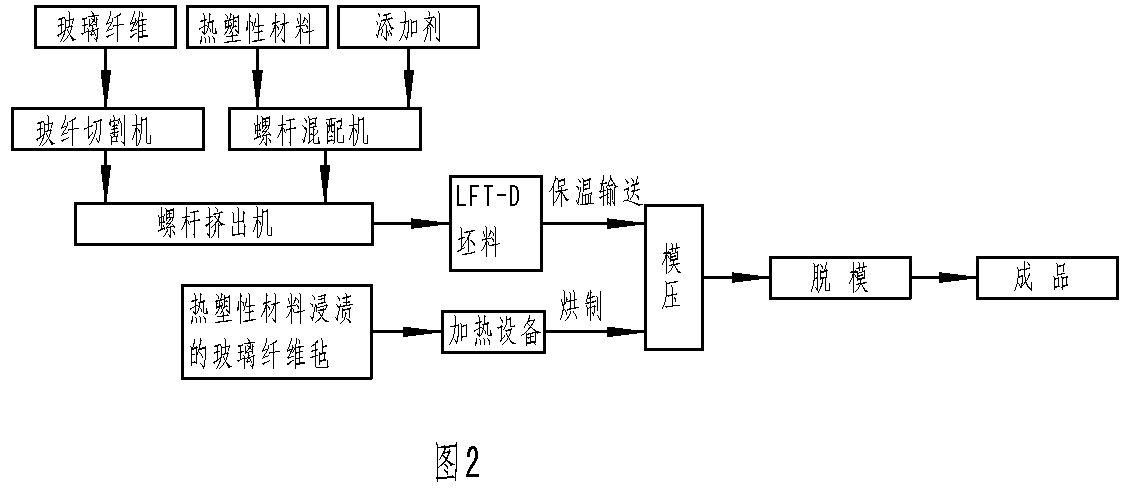

[0029] refer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com