Automobile bottom deflector made of LFT-D (Fiber Reinforce Thermoplastic-Direct) material and manufacture method thereof

A deflector and automobile technology, which is applied to vehicle parts, body, streamlined body, etc., can solve the problems of backward special equipment and low technical level, and achieve the effects of short production cycle, flexible selection and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

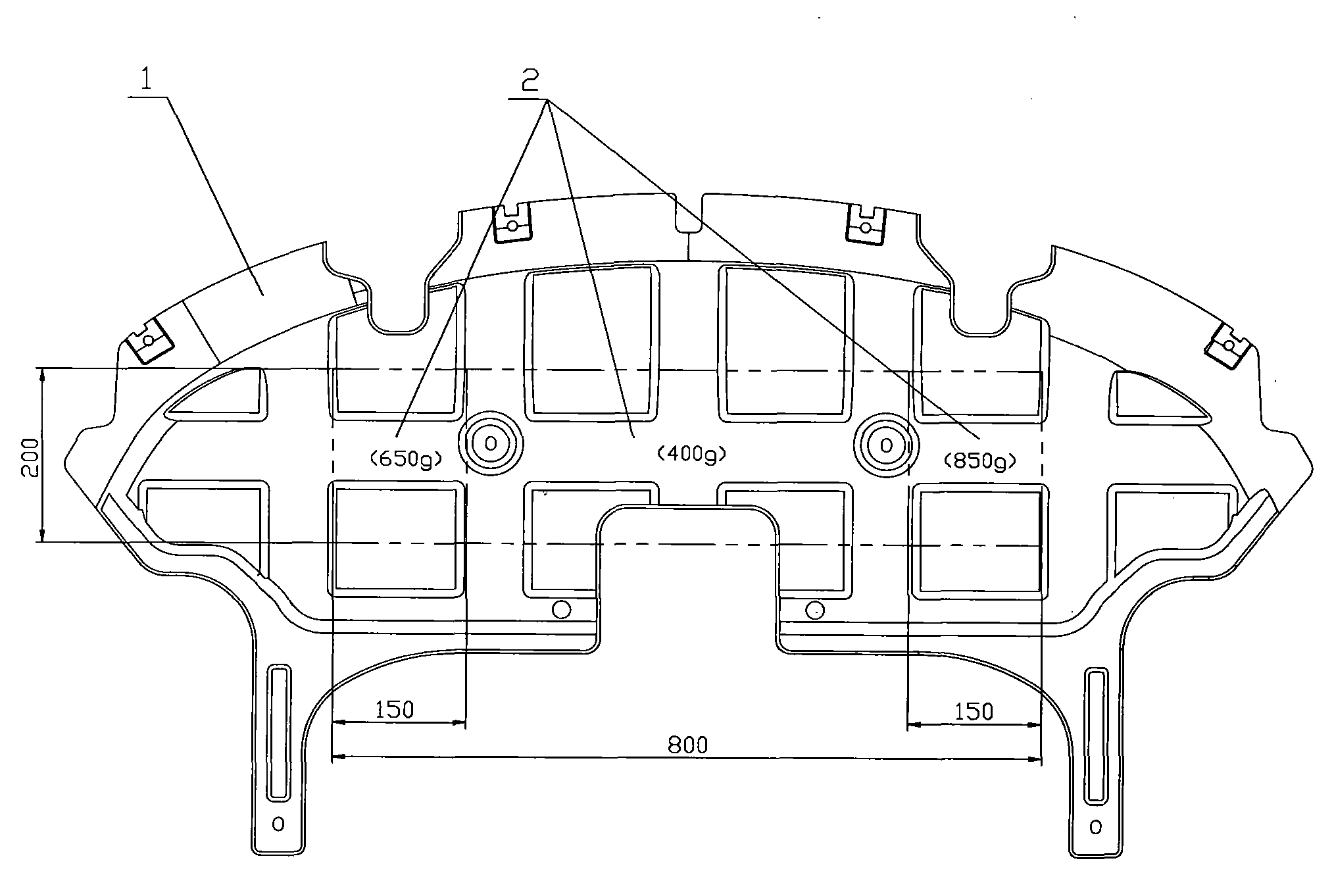

[0018] A car bottom deflector made of LFT-D material and a manufacturing method thereof, the raw materials of the LFT-D are: resin (polypropylene PP), glass fiber (25% to 30% of the total mass of raw materials), additives (resistance flammable agents, antioxidants, adhesion promoters). Wherein, the LFT-D is the abbreviation of Long-Fiber Reinforced Thermoplastic Direct; the polypropylene PP is a thermoplastic resin obtained by polymerizing propylene.

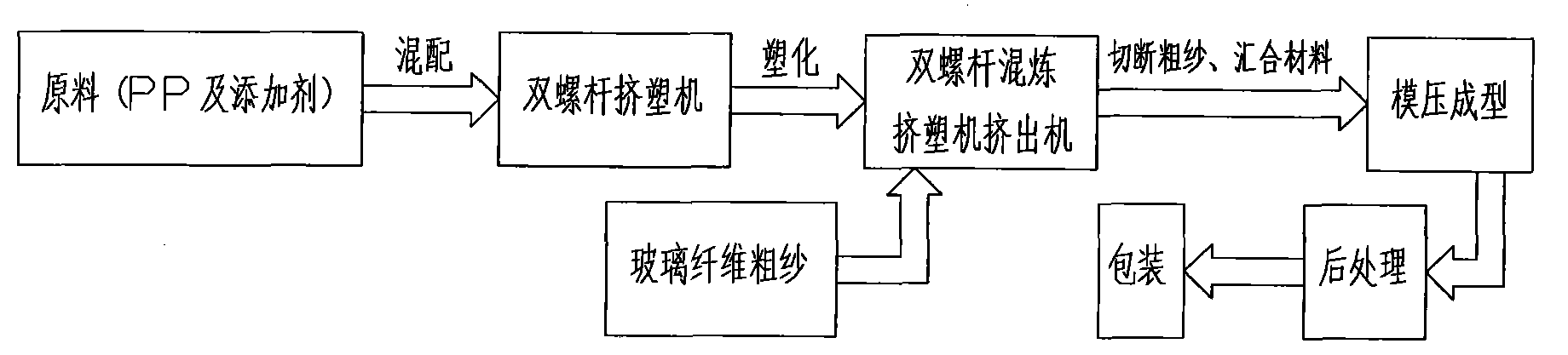

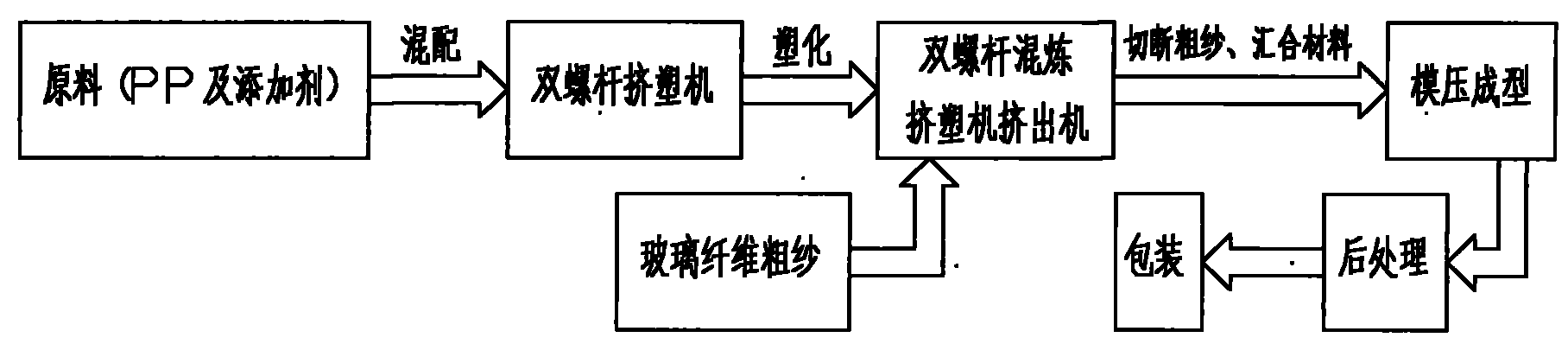

[0019] see figure 1 , figure 2 , the production process of the manufacture of the automobile bottom deflector of the LFT-D material is: the polymer matrix particles (mainly polypropylene PP) and additives are delivered to the gravity mixing metering unit, according to the automobile bottom defl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com