A kind of polyethylene powder coating for anti-corrosion steel pipe and preparation method thereof

A technology of polyethylene powder and anti-corrosion steel pipe, applied in the field of coatings, to achieve the effect of simple construction, broad market space, and smooth surface of the coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

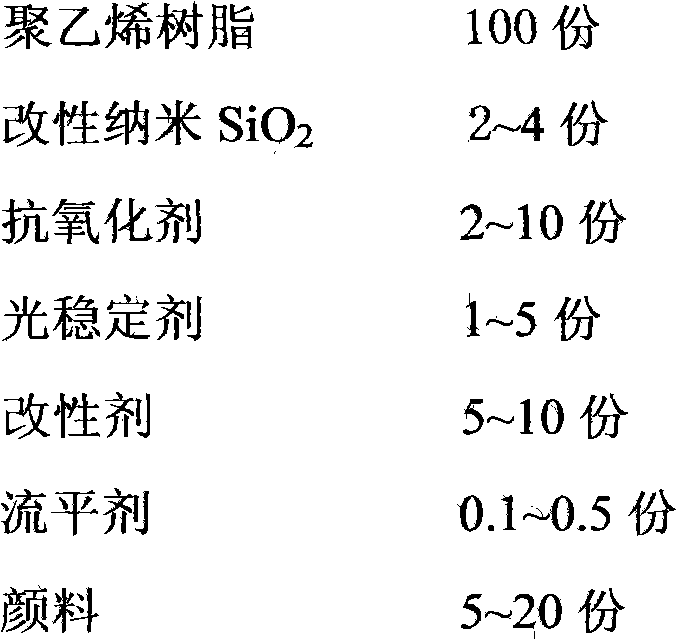

[0022] Polyethylene powder coating for anticorrosive steel pipe contains the following components (parts by weight):

[0023]

[0024] Preparation: Mix polyethylene and other various additives according to the formula and put them into a twin-screw extruder for melting, extrusion and granulation. The product is pulverized into fine powder by a plastic pulverizer and sieved, taking 180-200 The target component is sufficient.

[0025] The nano SiO 2 The modification method is: the nano Si0 2 , The silane coupling agent KH-550 pair and acetone are added to the reaction vessel in a certain proportion. The amount of the silane coupling agent is 4% to 4.5% of the mass of nano silica, and the weight ratio of nano SiO2 to acetone is 1: 3. Heat in a water bath, gradually raise the temperature to 60°C, stir and oscillate ultrasonically, reflux at constant temperature for 30 minutes, filter with suction, wash with absolute ethanol three times, and dry to obtain surface-modified nano-SiO 2 .

Embodiment 2

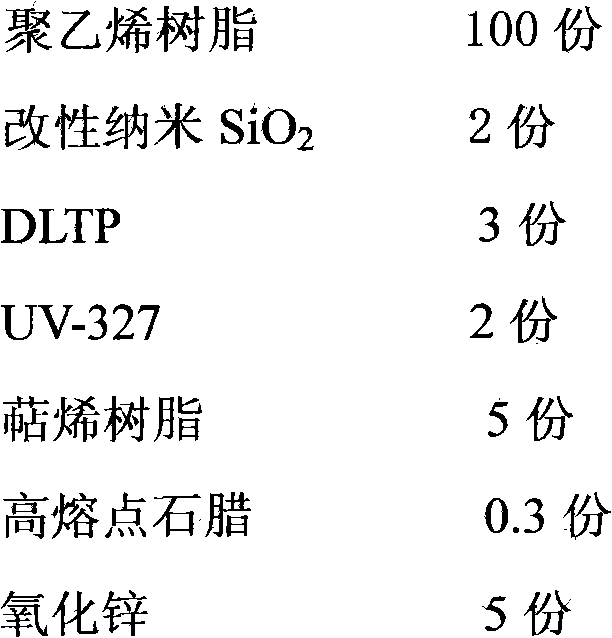

[0027] Polyethylene powder coating for anticorrosive steel pipe contains the following components (parts by weight):

[0028]

[0029] Preparation: Mix polyethylene and other various additives according to the formula and put them into a twin-screw extruder for melting, extrusion and granulation. The product is pulverized into fine powder by a plastic pulverizer and sieved, taking 180-200 The target component is sufficient.

[0030] The nano SiO 2 The modification method is: the nano SiO 2 , The silane coupling agent KH-550 pair and acetone are added to the reaction vessel in a certain proportion. The amount of the silane coupling agent is 4% to 4.5% of the mass of nano silica, and the weight ratio of nano SiO2 to acetone is 1: 3. Heat in a water bath, gradually raise the temperature to 60°C, stir and oscillate ultrasonically, reflux at constant temperature for 30 minutes, filter with suction, wash with absolute ethanol three times, and dry to obtain surface-modified nano-SiO 2 .

Embodiment 3

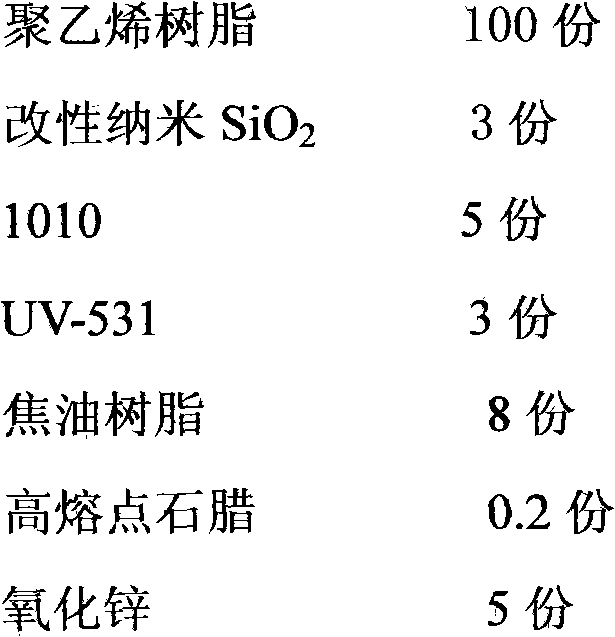

[0032] Polyethylene powder coating for anticorrosive steel pipe contains the following components (parts by weight):

[0033]

[0034] Preparation: Mix polyethylene and other various additives according to the formula and put them into a twin-screw extruder for melting, extrusion and granulation. The product is pulverized into fine powder by a plastic pulverizer and sieved, taking 180-200 The target component is sufficient.

[0035] The nano SiO 2 The modification method is: the nano SiO 2 , The silane coupling agent KH-550 pair and acetone are added to the reaction vessel in a certain proportion. The amount of the silane coupling agent is 4% to 4.5% of the mass of nano silica, and the weight ratio of nano SiO2 to acetone is 1: 3. Heat in a water bath, gradually raise the temperature to 60°C, stir and oscillate ultrasonically, reflux at constant temperature for 30 minutes, filter with suction, wash with absolute ethanol three times, and dry to obtain surface-modified nano-SiO 2 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com