Gypsum and calcium oxide melt inclusion expansion clinker, concrete expansion agent, and preparation method and application thereof

A technology of expanding clinker and calcium oxide, which is applied in the application field of gypsum and calcium oxide molten inclusion concrete expansion agent and its preparation, improving the shrinkage resistance of concrete, and can solve the problem of short shelf life of expansion agent products and short storage time of expansion agent , Expansion clinker is easy to weather and other problems, to achieve the effect of long shelf life, large early expansion and easy firing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

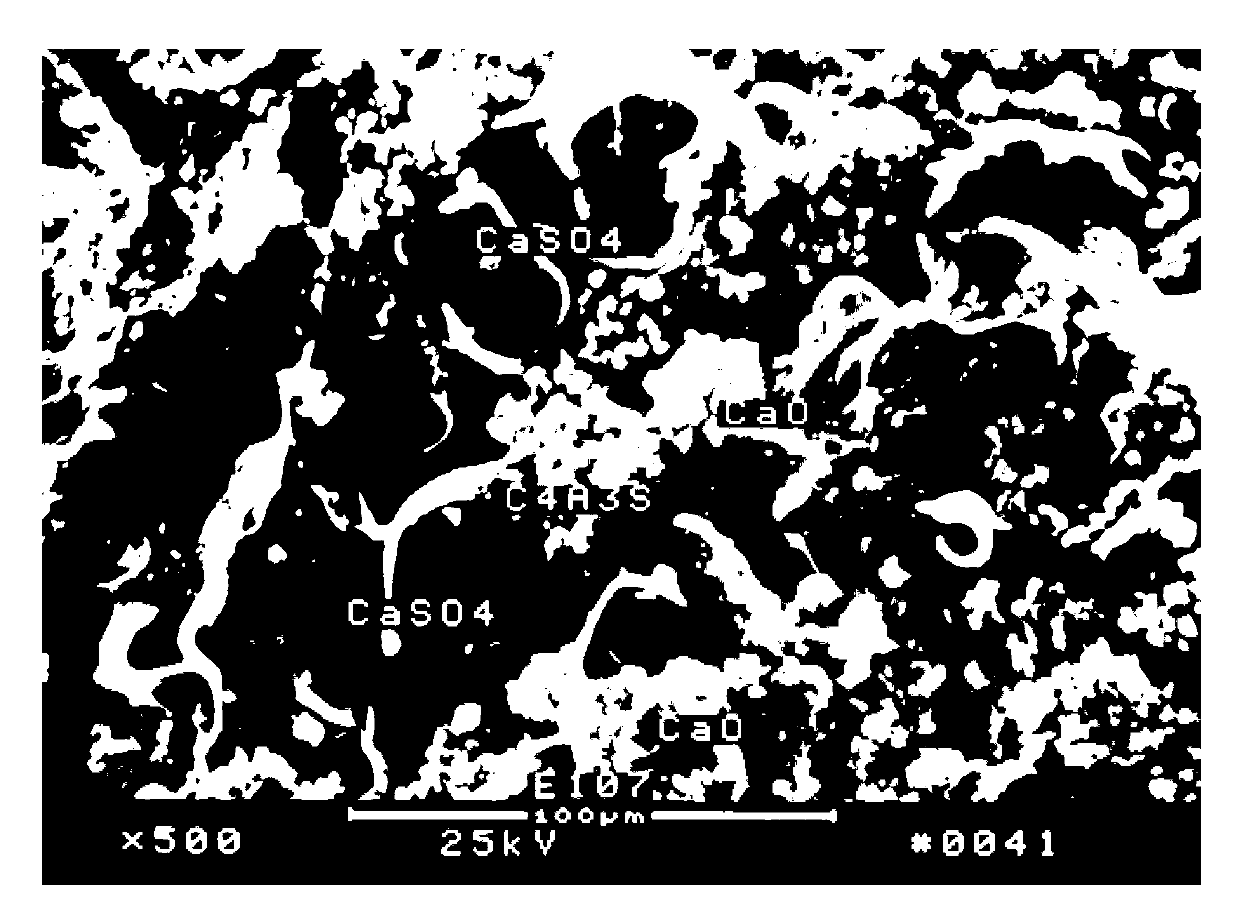

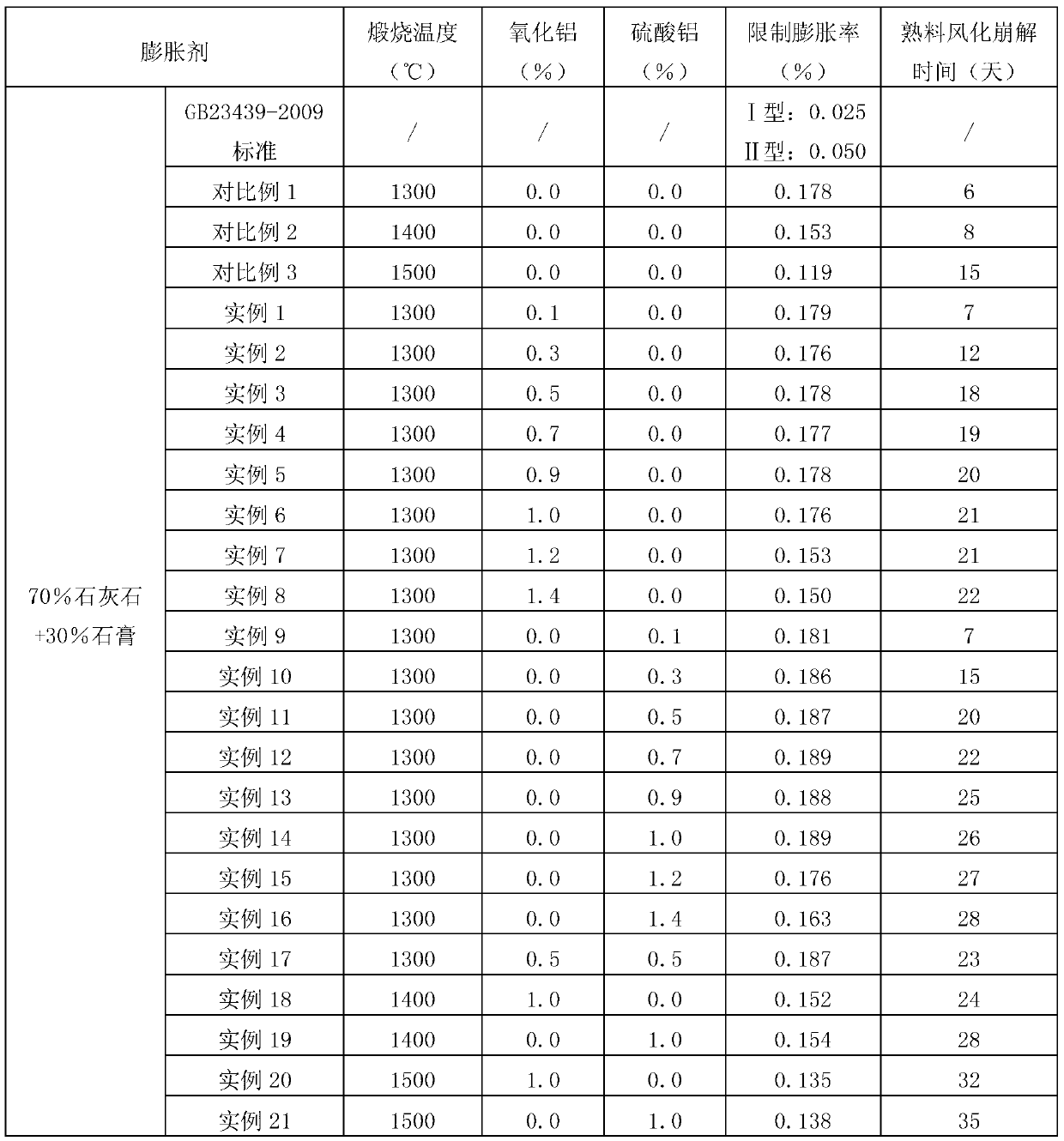

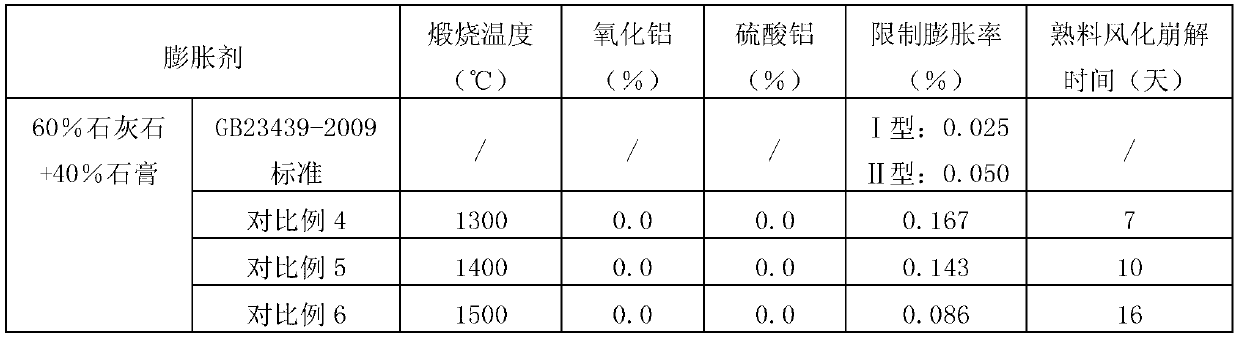

[0051] Example 1. Preparation of expanded clinker with gypsum and calcium oxide molten inclusions and its performance testing

[0052] According to the ratio shown in Table 1, 40wt%-80wt% limestone (calcium carbonate), 20wt%-60wt% gypsum (anhydrite), and 0.1wt%-1.4wt% aluminum oxide and / or sulfuric acid Aluminum (with no addition of alumina and / or aluminum sulfate as a comparative example) is co-ground to a specific surface area of 350m 2 / kg (140-400m 2 / kg) to make a cake with a diameter of 100mm and a thickness of 15mm. After drying at 105°C, put it into an electric furnace for calcination, and then calcine at a constant temperature of 1300°C-1500°C for 120min. The material cake is taken out from the electric furnace and rapidly cooled to obtain clinker.

[0053] Take part of the clinker and grind it to a specific surface area of 350m 2 / kg, refer to the current national standard "Concrete Expansion Agent" GB23439-2009 to test the limited expansion rate. Take anothe...

Embodiment 2

[0083] Example 2. Preparation of gypsum and calcium oxide molten inclusion concrete expansion agent and its performance testing

[0084] The preparation method of the gypsum and calcium oxide molten inclusion concrete expansion agent of the present invention comprises the following steps:

[0085] 1) As shown in Table 5, mix 40wt%-80wt% limestone (calcium carbonate), 20wt%-60wt% gypsum (anhydrite) and 0.1wt%-1.0wt% alumina and / or aluminum sulfate co-grind to a specific surface area of 350m 2 / kg (140-400m 2 / kg), calcined at a constant temperature of 1350°C in a rotary kiln with a diameter of 1600mm and expanded to 1900mm. The expanded clinker of gypsum and calcium oxide fusion inclusions is obtained.

[0086] 2) According to the ratio shown in Table 5, mix 20wt%-80wt% gypsum and calcium oxide fusion inclusion expansion clinker, 0.05wt% calcium stearate and 0.05wt% triethanolamine mixture, 20wt%-80wt% sulfoaluminic acid Calcium cement clinker (purchased from Xinmi, Henan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com