Flame-retardant nylon resin composition and preparation method thereof

A technology of nylon resin and composition, which is applied in the field of flame-retardant nylon resin composition and its preparation, and can solve the problems of poor heat resistance, limited application, and easy combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A preparation method of the above-mentioned flame-retardant nylon resin composition, comprising the steps of:

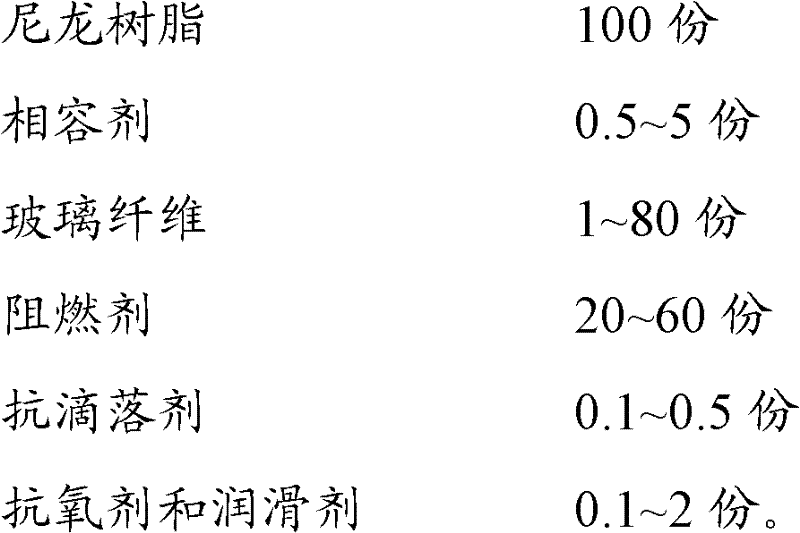

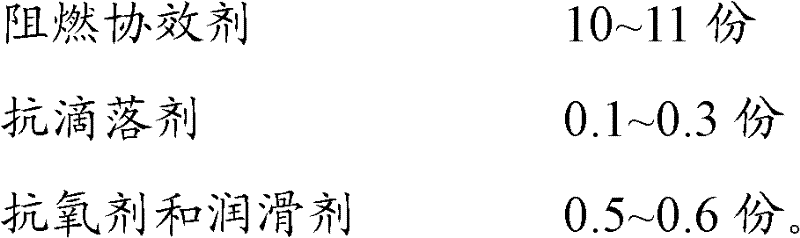

[0040] Each component of following parts by weight is provided:

[0041]

[0042]

[0043] Pour the above components into a mixer and stir evenly, and place them in a twin-screw extruder with a screw speed of 42Hz. The temperature settings in each zone of the twin-screw extruder are: 260°C for the first zone, 260°C for the second zone, and 270°C for the third zone. ℃, zone 4 270℃, zone 5 270℃;

[0044] extruding, adding glass fibers in proportion to the weight at the fiber-filling hole of the twin-screw extruder, and pelletizing to obtain a flame-retardant nylon resin composition.

[0045] The preparation method has the advantages of simple principle, low cost and low requirements on equipment, and the prepared flame-retardant nylon resin composition has good performance and can be widely popularized and applied.

Embodiment 1

[0052] The composition ratio of the following table is prepared (1 part=100 grams):

[0053] PA66

100 copies

GMA-G-EMA

1 copy

Fiberglass (Big Rock 988A)

50 copies

brominated polystyrene

45 copies

10 copies

Anti-dripping agent PTFE

0.1 part

Antioxidant 4,4'-thiobis(6-tert-butyl-3-methylphenol)

0.3 parts

Lubricant EBS

0.2 parts

[0054] Pour all the prepared materials except glass fiber into the mixer and stir evenly, and place them in the twin-screw extruder, the screw speed is 42Hz, and the set temperature is: 260°C for the first zone, 260°C for the second zone, and 270°C for the third zone. ℃, 270 ℃ in the fourth zone, 270 ℃ in the fifth zone, extrude, and at the same time add 50 parts of glass fiber in proportion to the weight of the fiber hole of the screw, and granulate to obtain a flame-retardant nylon resin composition.

[0055] Performance test results:

...

Embodiment 2

[0058] The composition ratio of the following table is prepared (1 part=100 grams):

[0059] PA66

100 copies

MAH-G-POE

5 copies

Fiberglass (Big Rock 988A)

60 copies

brominated epoxy resin

42 copies

11 copies

Anti-dripping agent PTFE

0.3 parts

Antioxidant 4,4'-thiobis(6-tert-butyl-3-methylphenol)

0.3 parts

Lubricant EBS

0.2 parts

[0060] Pour all the prepared materials except glass fiber into the mixer and stir evenly, and place them in the twin-screw extruder, the screw speed is 42Hz, and the set temperature is: 260°C for the first zone, 260°C for the second zone, and 270°C for the third zone. ℃, 270 ℃ in the fourth zone, 270 ℃ in the fifth zone, extrude, and at the same time add 60 parts of glass fiber in proportion to the weight of the fiber hole of the screw, and granulate to obtain a flame-retardant nylon resin composition.

[0061] Performance test results: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com