Waterborne acrylic ester-polyurethane resin emulsion and application thereof

A technology of water-based acrylate and polyurethane resin, which is applied in the field of polymer emulsion, can solve problems that have not been reported, and achieve good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

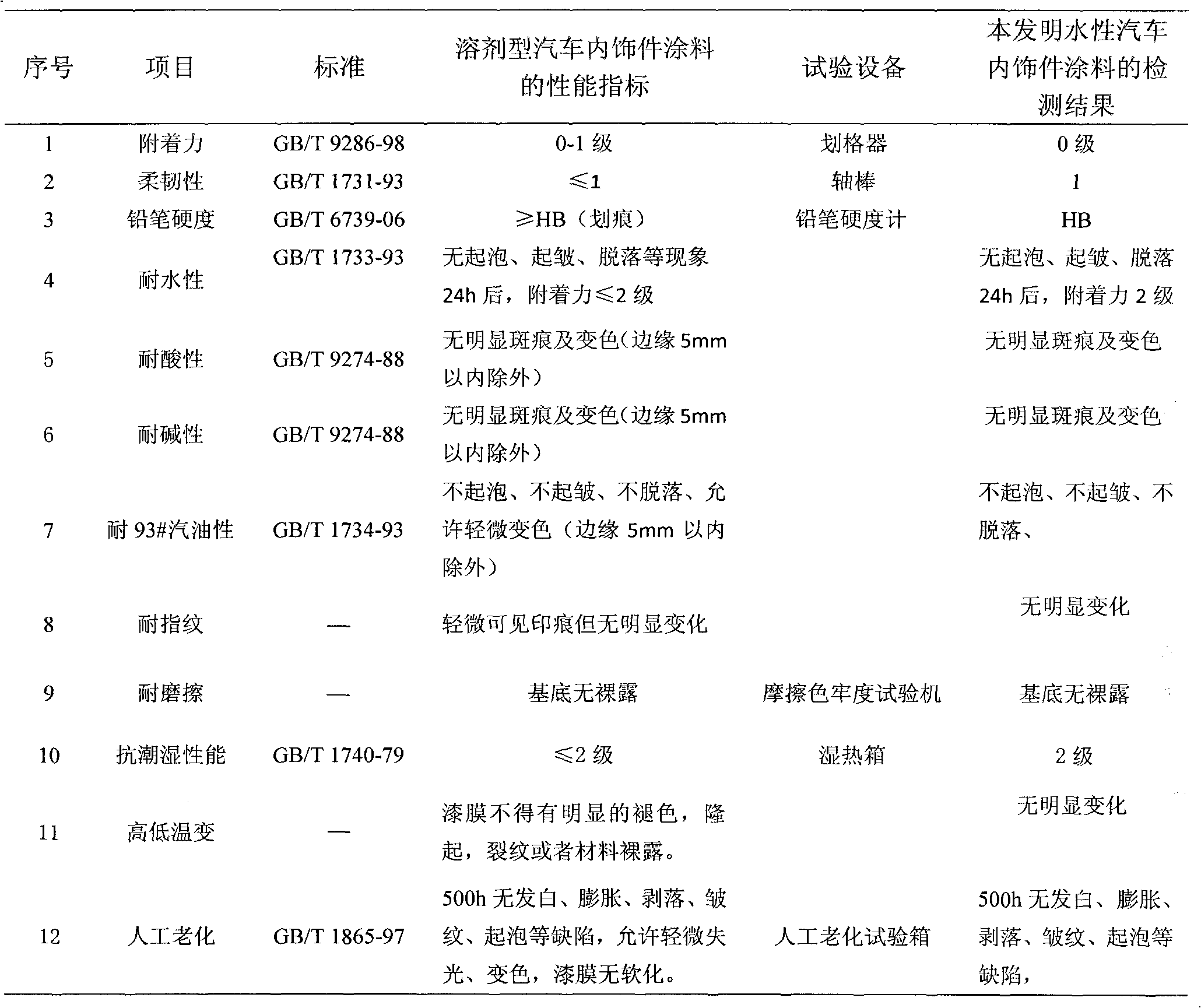

Examples

Embodiment 1

[0038] Embodiment 1 The preparation of aqueous acrylic acid-polyurethane resin emulsion

[0039] Waterborne polyurethane was prepared as follows:

[0040] To the equipment with stirring device, thermometer, N 2 Add 45gPPG, 10gHDO, 5gDMPA to the inlet and condensing reflux four-necked glass flask, vacuum dry and dehydrate at 100°C for 2h, cool down to 80°C, add 12gN-methylpyrrolidone, stir to completely dissolve DMPA, then start to drop 44gTDI Add 0.1g of di-n-butyltin dilaurate to the mixed solution with methyl ethyl ketone (50 / 50), drop it for about 1 hour, continue to stir for 4 hours, cool to 60°C, add 0.01g of hydroquinone, drop 8g of HEA, Add 5g of ethanol, react for 1h, add 6gTEA to neutralize for 0.5h; add 200g of water, disperse at high speed for 0.5h, spin out butanone, and get a translucent water-based polyurethane emulsion (WPU), with a solid content of 30%.

[0041] The core-shell structure waterborne acrylic acid-polyurethane hybrid is prepared as follows:

[0...

Embodiment 2

[0043] Embodiment 2 The preparation of aqueous acrylic acid-polyurethane resin emulsion

[0044] Waterborne polyurethane was prepared as follows:

[0045] To the equipment with stirring device, thermometer, N 2 Add 50gPPG, 15gHDO, 7gDMPA to the entrance and condensing reflux four-neck glass flask, vacuum dry and dehydrate at 100°C for 2h, cool down to 80°C, add 15gN-methylpyrrolidone, stir to dissolve DMPA completely, then start to drop 50gTDI Add 0.15g of di-n-butyltin dilaurate to the mixed solution of butanone (50 / 50), and drop it for about 1 hour. Continue to stir for 4 hours and cool to 60°C. Add 0.01g of hydroquinone and 5g of HEA dropwise. After 20 minutes of dripping, keep warm for 4 hours; add 6g of ethanol, add 4gTEA to neutralize to a pH of about 8 after 1 hour of reaction; add 230g of water, disperse at a high speed for 0.5h, and spin out methyl ethyl ketone to obtain a translucent water-based polyurethane emulsion (WPU). 33%.

[0046] The core-shell structure w...

Embodiment 3

[0048] Embodiment 3 The preparation of aqueous acrylic acid-polyurethane resin emulsion

[0049] Waterborne polyurethane was prepared as follows:

[0050] To the equipment with stirring device, thermometer, N 2 Add 56gPPG, 8gHDO, 5gDMPA to the inlet and condensing reflux four-neck glass flask, vacuum dry and dehydrate at 100°C for 2h, cool down to 80°C, add 15gN-methylpyrrolidone, stir to completely dissolve DMPA, then start to drop 50gTDI Add 0.15g of di-n-butyltin dilaurate to the mixed solution of butanone (50 / 50), drop it for about 1 hour, continue to stir for 4 hours, cool to 60°C, add 0.01g of hydroquinone, drop 8g of HEA, Add 4g of ethanol, react for 1h, add 6gTEA to neutralize for 0.5h; add 250g of water, disperse at a high speed for 0.5h, spin out methyl ethyl ketone, and obtain a translucent water-based polyurethane emulsion (WPU), with a solid content of 35%.

[0051] The core-shell structure waterborne acrylic acid-polyurethane hybrid is prepared as follows:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com