Continuously strong bridge structure with variable concrete density gradient

A rigid-frame bridge and concrete technology, which is applied to bridges, bridge parts, bridge materials, etc., can solve the problems of low tensile strength, difficult construction, and high maintenance costs, so as to improve cracking strength, reduce adverse effects, and reduce The effect of structural self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

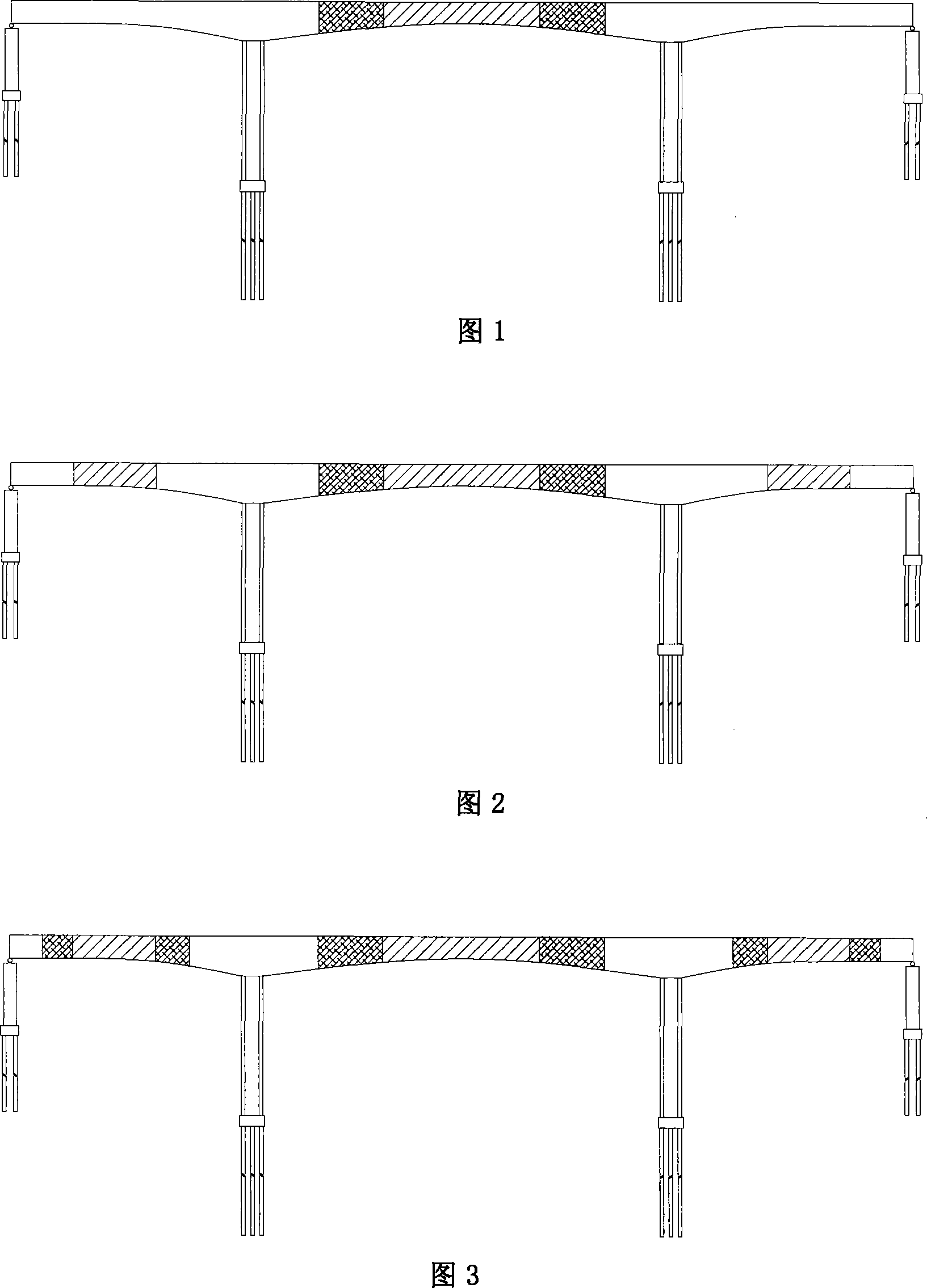

Embodiment 1

[0020] At present, there is no continuous rigid frame bridge with concrete density gradient change at home and abroad. Only a few foreign countries have introduced high-strength lightweight aggregate concrete into the mid-span of continuous rigid-frame bridges, and built continuous rigid-frame bridges whose superstructure is composed of high-strength lightweight aggregate concrete and high-strength ordinary concrete, achieving a lightweight structure. Self-weight to optimize the mechanical properties of the structure. For example, the Stolma continuous rigid frame bridge with a main span of 301m built in Norway in 1998 used high-strength ordinary concrete at 58.5m of the pier-beam consolidation on both sides, and high-strength lightweight aggregate concrete at the middle span of 184m. However, after this type of bridge is completed and put into operation, a large number of oblique cracks still appear in the main beam web between the mid-span and the pier-beam consolidation, wh...

Embodiment 2

[0047] In this example, a continuous rigid frame bridge structure with concrete density gradient changes is proposed. In the mid-span and side-span mid-span, dry high-strength lightweight aggregate concrete with low apparent density is introduced, and high-strength aggregate concrete is applied through the mid-span and side spans. Light aggregate concrete further reduces the weight of the structure; the pier-beam consolidation of the middle span is made of high-strength ordinary concrete to meet the high compressive and cracking strength requirements of the pier-beam consolidation; the mid-span of the mid-span and the pier-beam consolidation Fiber-toughened and anti-crack high-strength sub-lightweight concrete is introduced into the main beams in between, which not only reduces the self-weight of the structure, reduces the impact of shrinkage and creep, but also enhances the crack resistance of the structure. The above three concrete materials are applied to the middle span of ...

Embodiment 3

[0052] In this example, a continuous rigid frame bridge structure with concrete density gradient changes is proposed. According to the stress condition of the continuous rigid frame bridge, high-strength lightweight aggregate concrete with low apparent density is introduced into the mid-span and side span. Further reduce the self-weight of the structure; the pier-beam consolidation of the mid-span and side spans are all made of high-strength ordinary concrete, which meets the high compressive and cracking strength requirements of the pier-beam consolidation; The main beams between the places are all introduced with fiber-toughened and crack-resistant high-strength sub-lightweight concrete, which not only reduces the structural weight, reduces the impact of shrinkage and creep, but also enhances the structural crack resistance. The above three concrete materials are all applied to the mid-span and mid-span of the continuous rigid frame bridge. By optimizing the combination and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com