Composite box girder bridge erected in advance by using corrugated steel web steel girders and construction method thereof

A technology of steel webs and combined boxes, applied in the field of combined box girder bridges and their construction, can solve the problems that the self-weight internal force accounts for a large proportion of the designed internal force, affects the durability of the bridge's load-bearing performance, and the tensile strength is insufficient, so as to improve the construction quality , good social and economic effects, and the effect of improving live load efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

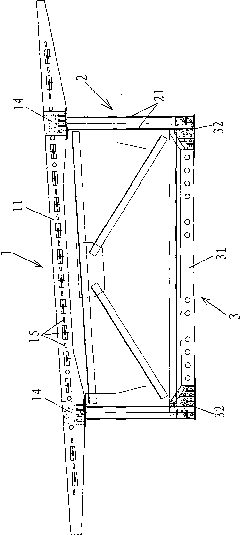

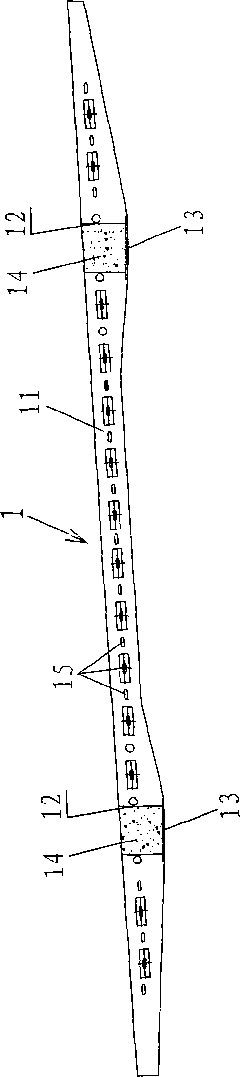

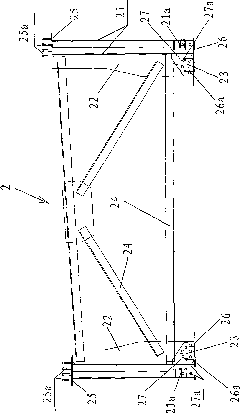

[0034] Such as Figure 1 to Figure 6 The shown one uses folded steel web steel girders to erect a composite box girder bridge in advance, including a concrete floor 3, a steel beam 2 and a concrete roof 1, the steel beam 2 is connected to the concrete floor 3 and the concrete roof 1 respectively, and the concrete floor 3 Installed on the steel beam 2, and bearing the concrete roof 1, the steel beam 2 is a folded steel web steel beam structure, and each steel beam 2 includes a pair of folded steel webs 21 vertically symmetrically arranged and erected on a pair of folded steel webs. The hollow-type diaphragm unit between the steel webs, the upper end of the folded steel web 21 is provided with an upper connection mechanism for fastening with the concrete roof 1, and the lower end of the folded steel web 21 is provided with an upper connection mechanism for connecting with the concrete bottom plate 3 Tighten the connected lower link mechanism.

[0035] The fasting diaphragm unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com