Accurate positioning method of sliding of full-support frame steel box girder

A precise positioning, steel box girder technology, applied in the erection/assembly of bridges, bridges, bridge construction, etc., can solve the problems of low construction efficiency, complicated procedures, delayed construction period, etc., to reduce equipment investment, simple procedures, and cost saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

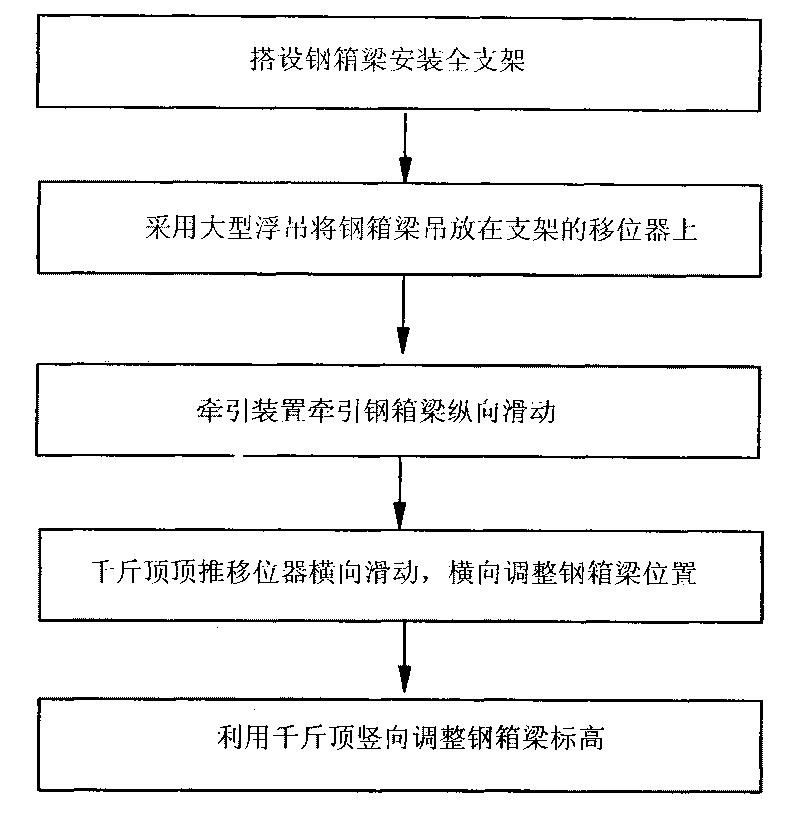

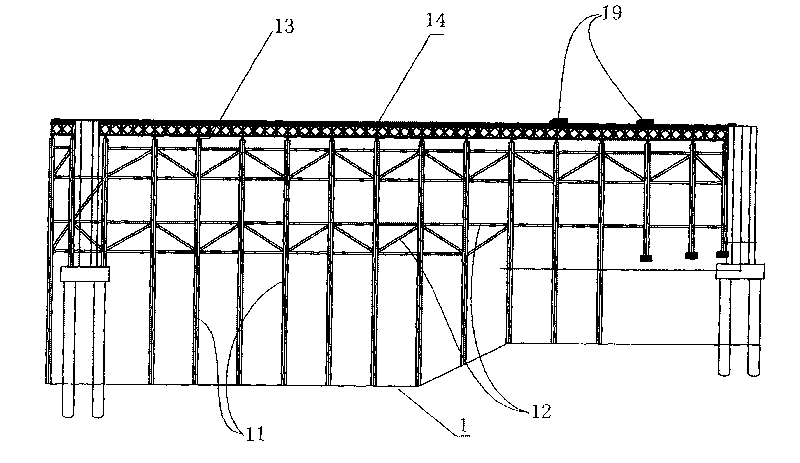

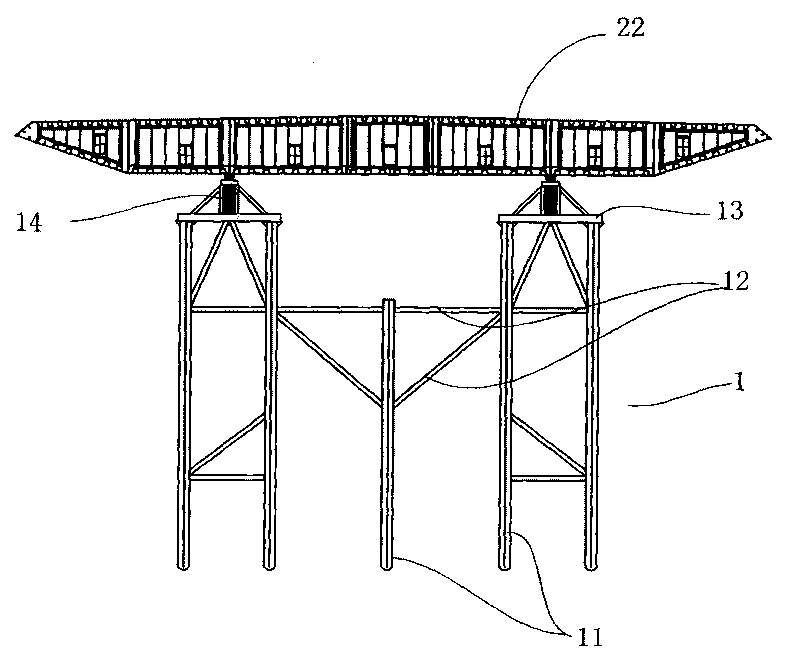

[0021] figure 1 It is a flow chart of the precise sliding positioning method for the steel box girder with full support of the present invention. The method of the present invention is to set up the full support before installing the steel box girder. The lower part of the whole bracket is a support system, the upper part is a sliding system, and the sliding system is provided with a shifter. After the erection of the whole bracket is completed, the steel box girder is hoisted on the shifter of the upper sliding system of the bracket by a large floating crane, and the longitudinal position of the steel box girder is adjusted through the longitudinal sliding of the steel box girder by the traction device; Positioner to adjust the horizontal position of the steel box girder; then use the jack to push the steel box girder vertically to adjust the elevation of the steel box girder. Through the adjustment of the above three directions, the precise positioning of the steel box gir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com