Integral two-way partial one-way steel-concrete slab composite floor and its construction method

A technology of concrete slab and two-way steel, which is applied to floors, building components, buildings, etc., can solve the problems of bearing capacity and seismic performance that cannot meet the requirements of large-span structures, increase the workload of node connection, and increase the number of nodes, etc. The effect of wet work, reducing the layout of the main beam, and improving the stiffness of the floor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

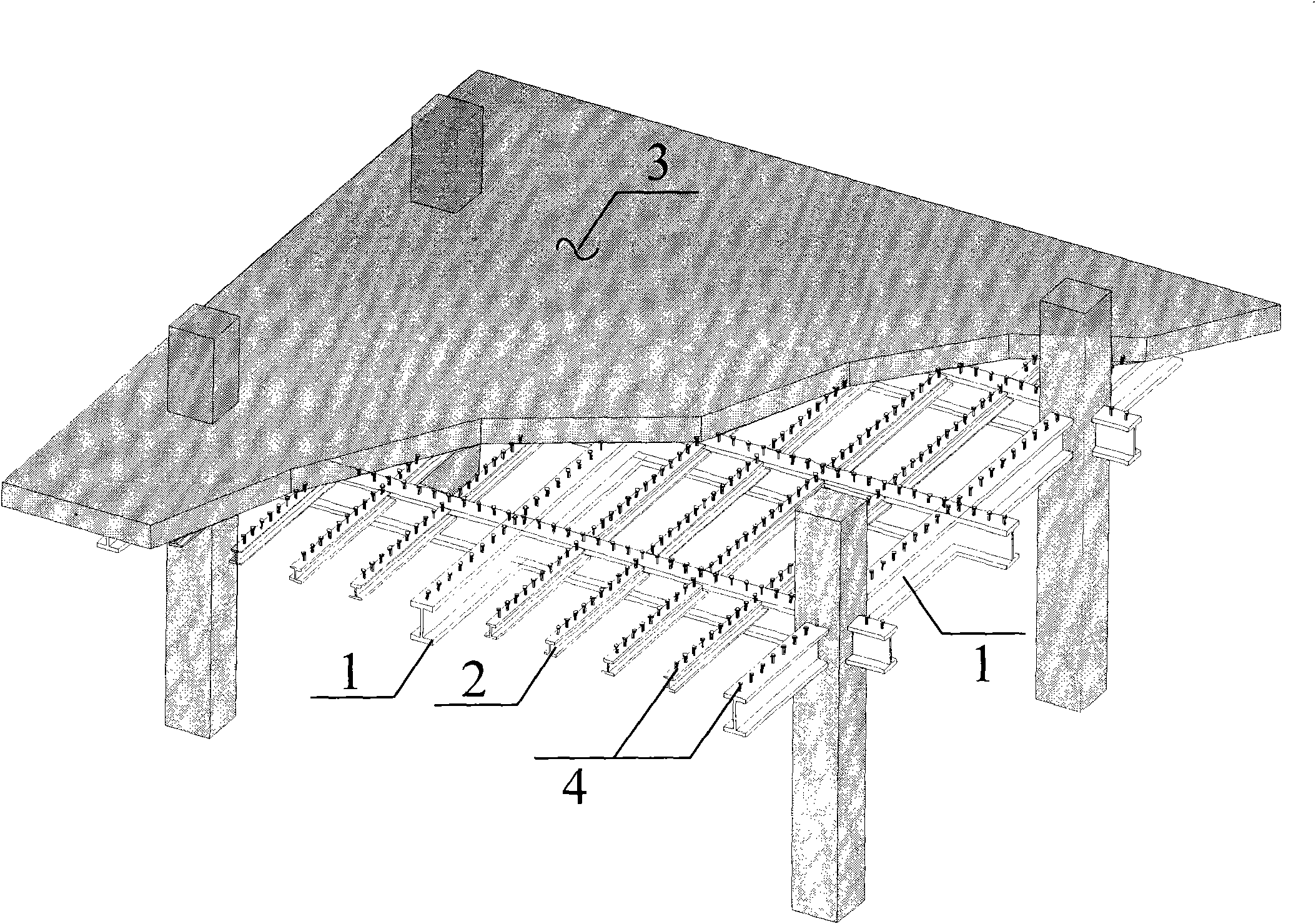

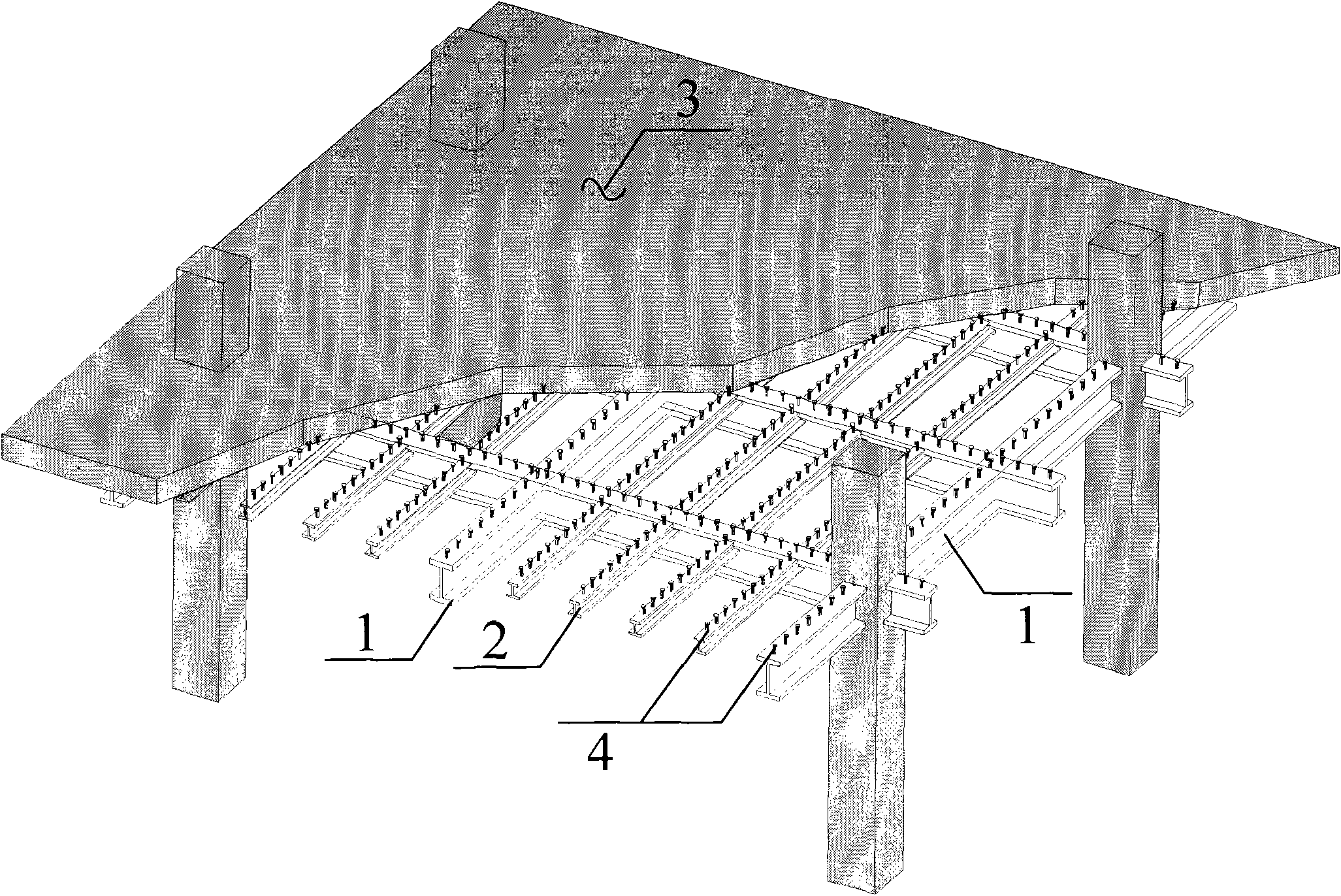

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] The overall two-way partial one-way steel-concrete slab composite floor provided by the present invention is composed of two-way steel main beam 1, one-way steel secondary beam 2, and concrete slab 3, and each part is combined into a whole by a shear connector 4 work together. The two-way steel girder 1 can be an I-shaped steel girder or a box-shaped steel girder, and is located on the lower floor of the floor. The connection between the two-way steel main girders 1 and the one-way steel secondary girders 2 can be bolted or welded, and the number, cross-sectional size and spacing of steel girders are determined according to the application requirements. The shear connector 4 can be in the form of studs, channel steel, etc., and is a component that connects the steel beam and the concrete slab to work together. The concrete slab 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com