Steel box girder erection method applied to steel and concrete hybrid girder cable-stayed bridge

A technology of steel box girders and concrete box girders, which is applied in cable-stayed bridges, bridge construction, erection/assembly of bridges, etc., and can solve problems such as inability to meet the erection requirements of ground transportation, limited spans of temporary buttresses, and the need for ground transportation channels, etc. , to achieve the effect of promoting the development of construction technology, solving construction technical problems and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

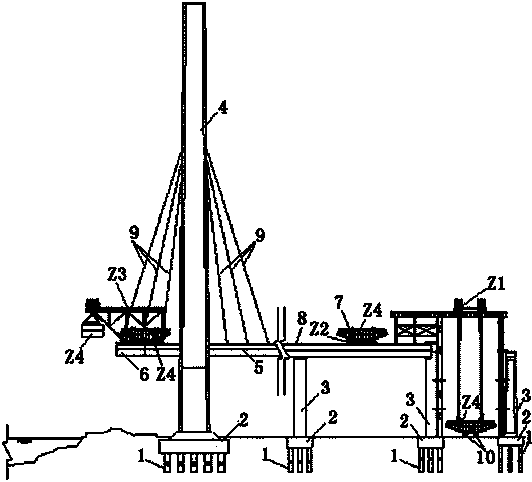

[0030] The present invention is applied to engineering example, provides a kind of new steel box girder erection method, in conjunction with accompanying drawing, specific implementation of the present invention is described as follows:

[0031] A. Construction of pile foundation (1), cap (2), pier body (3), cable tower (4), side-span concrete box girder (5) and steel-concrete combination section (6) is carried out in sequence, and the concrete box girder ( 5) The construction is completed with cast-in-place supports;

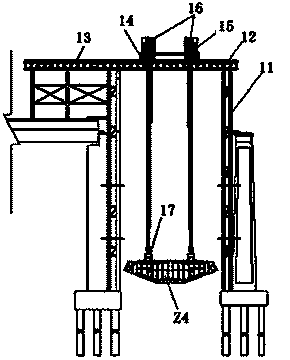

[0032] B. At the end of the bridge, use the foundation of the constructed cap (2) to install the girder door frame (Z1) that can lift the steel box girder (Z4) to the concrete beam surface of the side span in sections, and install the first to third pairs one by one during the period Stay cables (9) are tensioned symmetrically in pairs in sequence;

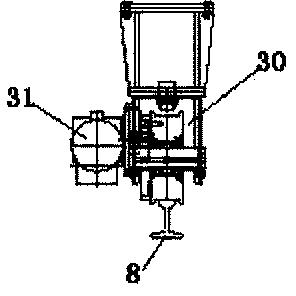

[0033] C. Assemble and anchor the cantilever bridge erecting machine (Z3) near the mid-span end of the concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com