Waterborne epoxy anti-corrosive coating and preparation method thereof

An anti-corrosion coating, water-based epoxy technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings and other directions, can solve the problem of not being able to achieve the construction, physical and chemical properties of solvent-based epoxy coatings at the same time, and achieve excellent construction performance. , high wear resistance, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

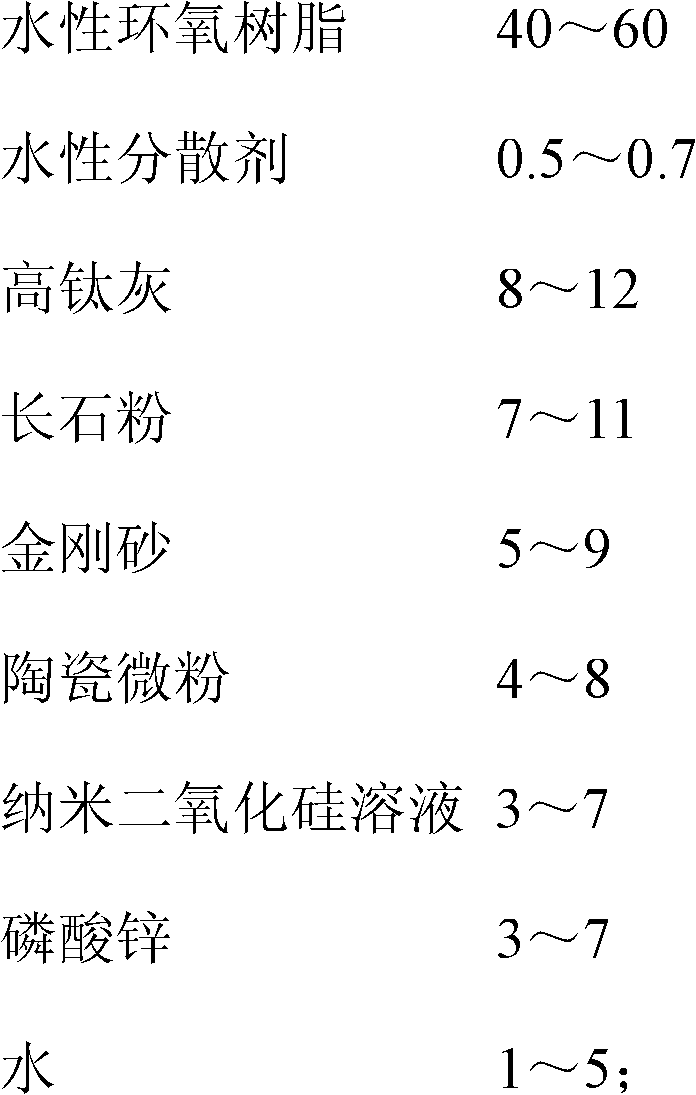

[0039]

[0040] Wherein, component B is a water-based epoxy curing agent, and the mass ratio of component A to component B is 6:1.

[0041] It is prepared according to the preparation method provided by the present invention by adding materials according to the above proportioning ratio.

Embodiment 2

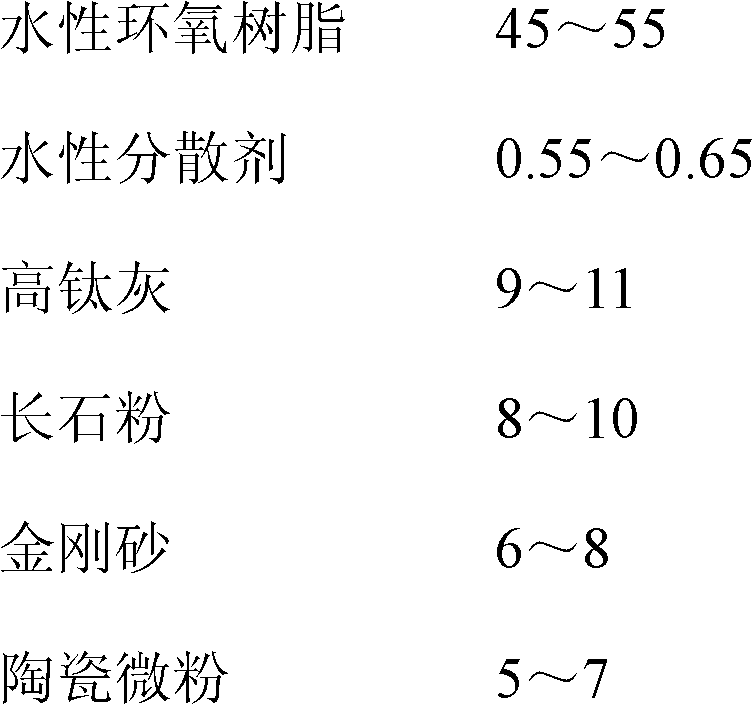

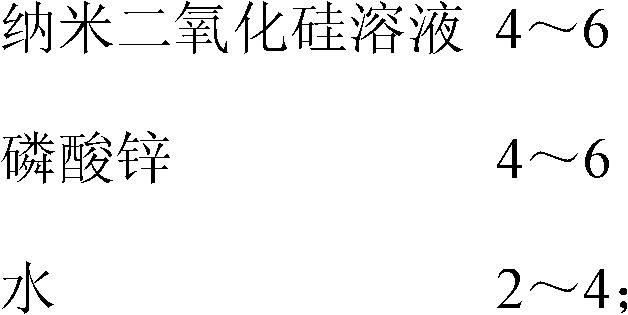

[0043]

[0044] Wherein, component B is a water-based epoxy curing agent, and the mass ratio of component A to component B is 5:1.

[0045] It is prepared according to the preparation method provided by the present invention by adding materials according to the above proportioning ratio.

Embodiment 3

[0047]

[0048]

[0049] Wherein, component B is a water-based epoxy curing agent, and the mass ratio of component A to component B is 7:1.

[0050] It is prepared according to the preparation method provided by the present invention by adding materials according to the above proportioning ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com