Walking type multi-point jacking-pushing construction method

A push-up construction and walking technology, applied in the erection/assembly of bridges, bridges, buildings, etc., to achieve the effect of low overall engineering cost, convenient operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

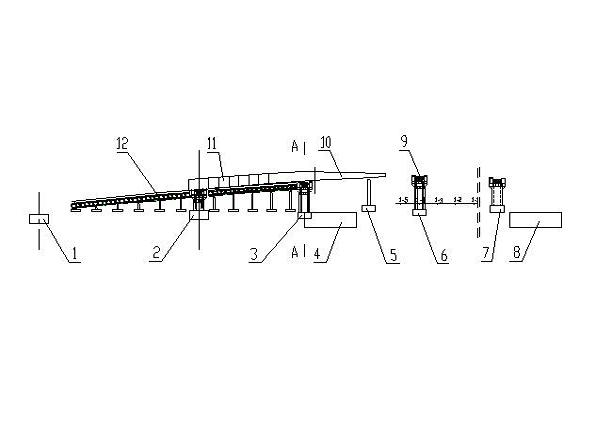

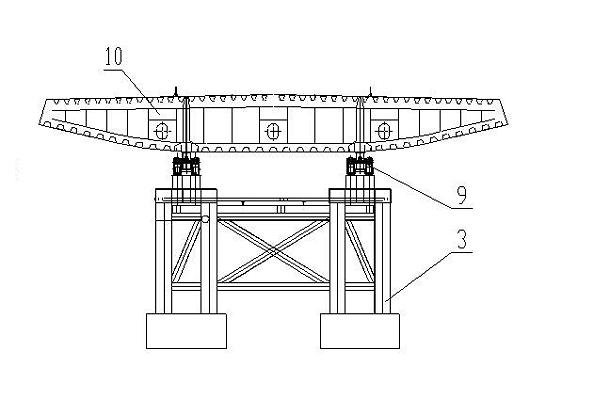

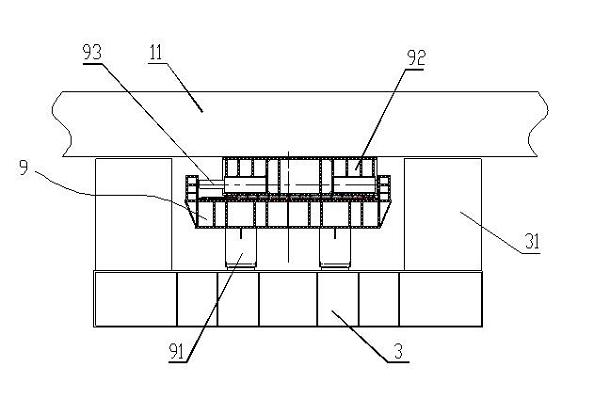

[0030] In this embodiment, a walking-type multi-point jacking construction method is used as figure 1 The length of the bridge erected between 2# pier 4 and 3# pier 8 is 220 meters as an example. From the left side of 2# pier 4, there are 0# pier 1 and 1# pier 2, and the preparatory work is in 1# pier 2 Set up a temporary pier with 2# pier 4, and use 1# pier 2 to erect a 7# temporary pier, and erect an 8# temporary pier 3 near the left side of 2# pier 4, between 0# pier 1 and 1# pier 2 Set up a pre-assembled platform 12 inclined from the ground to the design height of the pier as an approach bridge, and erect 1# temporary pier 5, 2# temporary pier 6, 3# temporary pier, and 4# temporary pier between 2# pier 4 and 3# pier 8 Pier, 5# temporary pier, 6# temporary pier 7, a total of 6 temporary pier. Inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com