Variable cross-section cantilever bridge box girder self-locking synchronization pushing system and construction method

A bridge box girder and variable cross-section technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of large loss of slide plates, low reuse rate, and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the drawings.

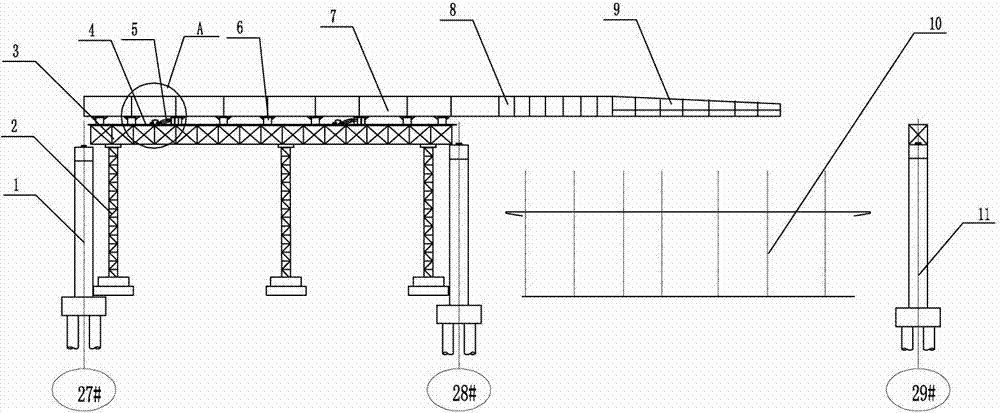

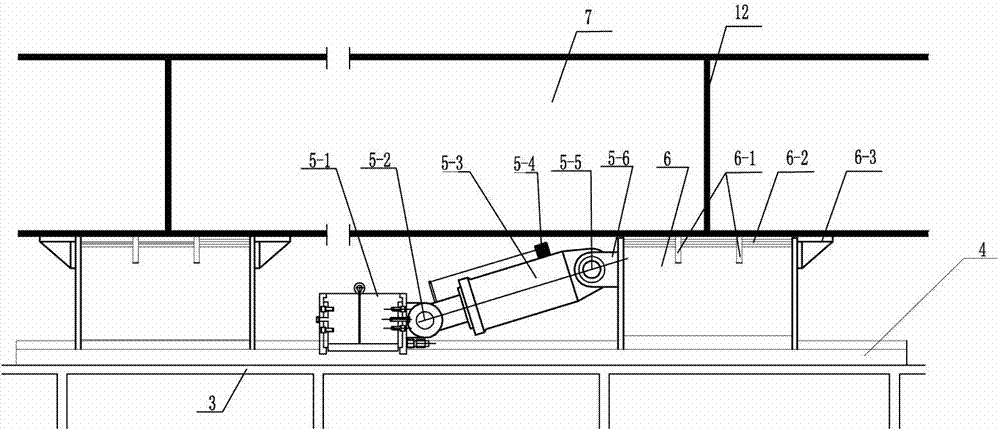

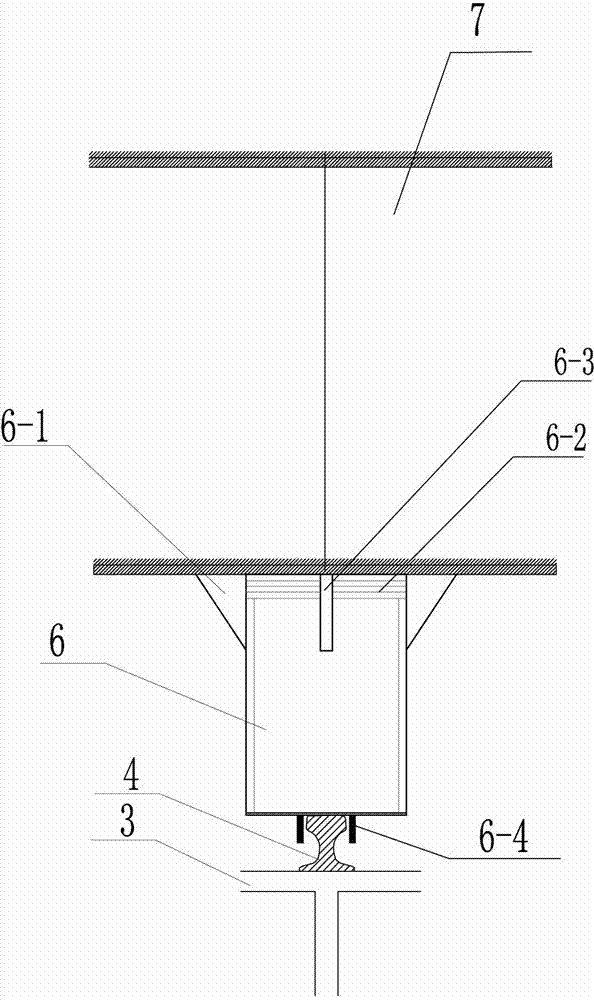

[0046] Such as Figure 1-4 As shown, the self-locking synchronous pushing system for box girder of variable cross-section cantilever bridge of the present invention includes a welding assembly platform system for pushing sliding bridge box girder arranged on the side of the railway, and the welding assembly platform for pushing sliding bridge box girder The system consists of a temporary support pier 2, a pushing sliding bridge box girder welding assembly platform 3 set on the temporary support pier 2, and a sliding track 4 set on the pushing sliding bridge box girder welding assembly platform 3 It consists of installing a set of sliding shoes 6 and a set of self-locking synchronous pushing devices 5 on the sliding track 4, and the set of self-locking synchronous pushing devices 5 are electrically connected to the automatic pushing control system. Features are:

[0047] The self-loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com