TFDS fault automatic recognition method

A technology of automatic identification and fault discrimination, applied in character and pattern recognition, measuring devices, instruments, etc., can solve the problem of low efficiency and achieve the effect of strong robustness, high efficiency and robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

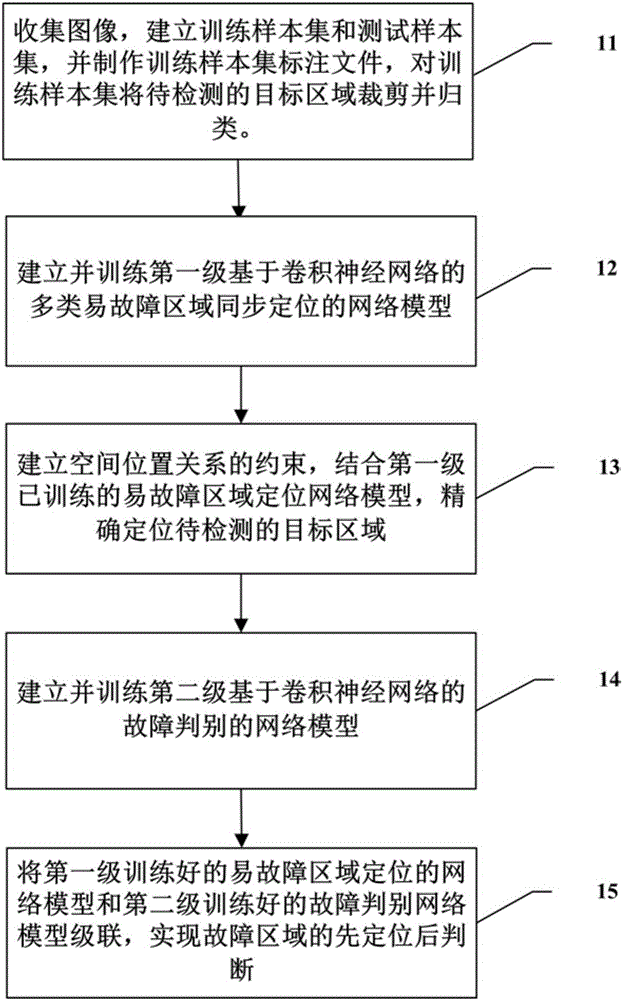

[0031] figure 1 It is a flow chart of the overall realization of the TFDS fault automatic identification method of the present invention, such as figure 1 As shown, the fault automatic identification method of the present invention comprises the following steps:

[0032] Step 11: Collect images, establish a training sample set and a test sample set, and make a training sample set annotation file, and crop and classify the target area to be detected for the training sample set.

[0033] The images collected by the dynamic detection system for fault images of railway freight cars (ie TFDS) are collected. The training sample set and the test sample set are randomly selected. The images in the test sample set are independent of the training sample set, and the images contained in the two have no intersection.

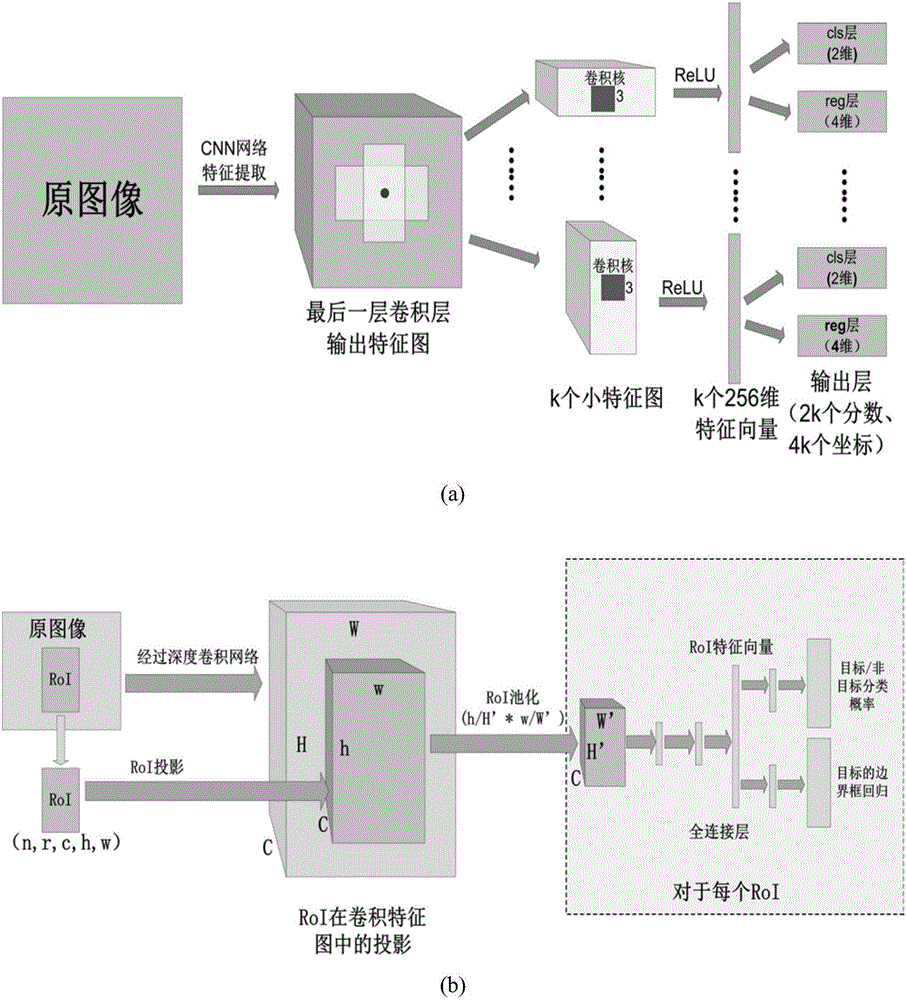

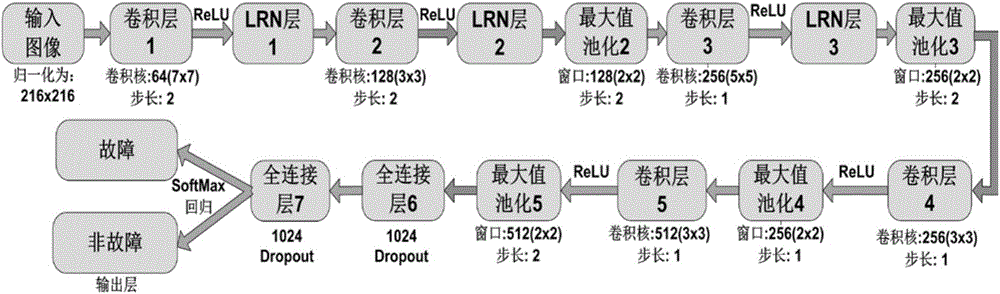

[0034] Make detailed anno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com