Device for measuring taper hole

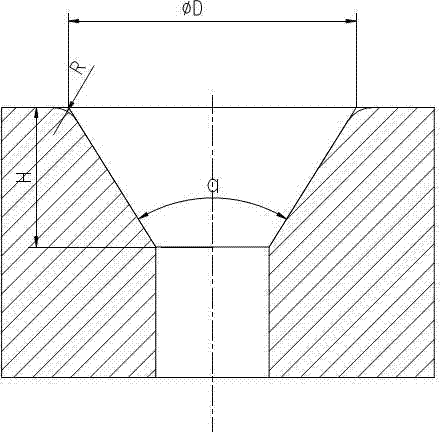

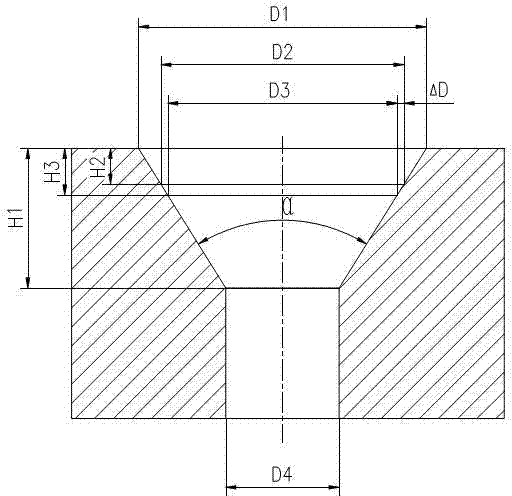

A measuring device and taper hole technology, which is applied in the direction of measuring device, mechanical measuring device, angle/taper measurement, etc., can solve the problems of expensive equipment and complicated operation, and achieve simple structure, low technical requirements and wide adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

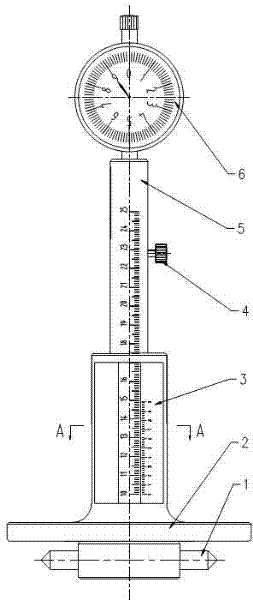

[0029] The details and working conditions of the specific device proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] A tapered hole measuring device of the present invention is mainly composed of a base (2), a sliding rod (5), a sliding core (8), a contact (1), and a dial indicator (6). The contact (1) is installed on In the hole at the lower end of the sliding rod (5), the sliding core (8) is installed inside the sliding rod (5), the dial indicator (6) is installed on the upper end of the sliding rod (5) through the expansion ring (10), and the sliding rod (5) The locking screw (4) on the top is used to limit the mutual position of the sliding core (8) and the sliding rod (5), and the springs (7) and (9) inside the sliding rod (5) ensure that the contact (1) and the sliding core (8) The contact is reliable. The sliding rod (5) is installed in the middle of the base (2). Through the window (3) on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com