Correction method of flow measurement properties of single-track ultrasonic water meter

A technology of flow measurement and correction method, applied in the field of household water meter measurement and detection, can solve the problems of difficult calculation, large measurement accuracy problem, too many correction points, etc., and achieve the effect of simple and fast calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Now to measure the inner diameter of the section , Take the example of an ultrasonic water meter.

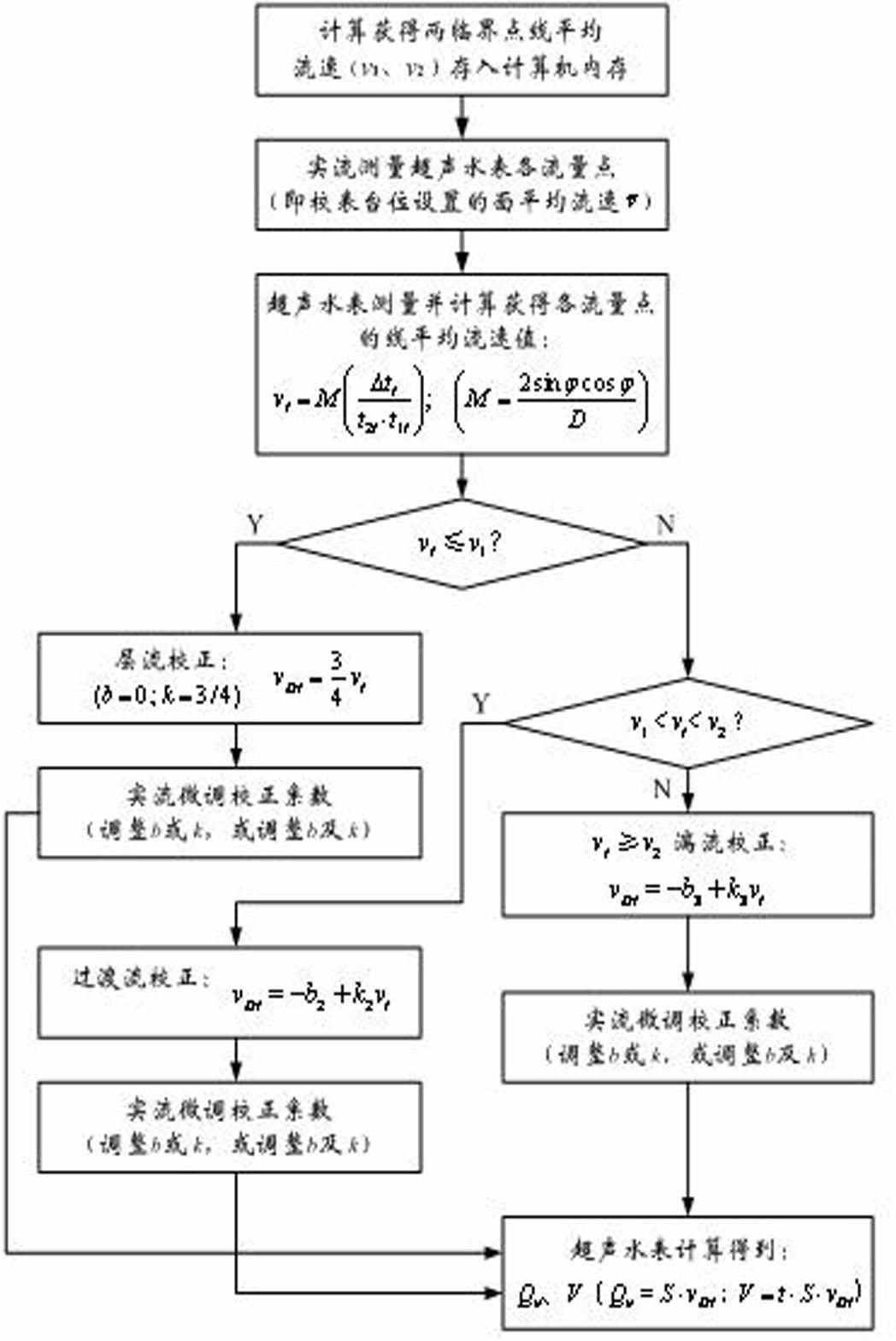

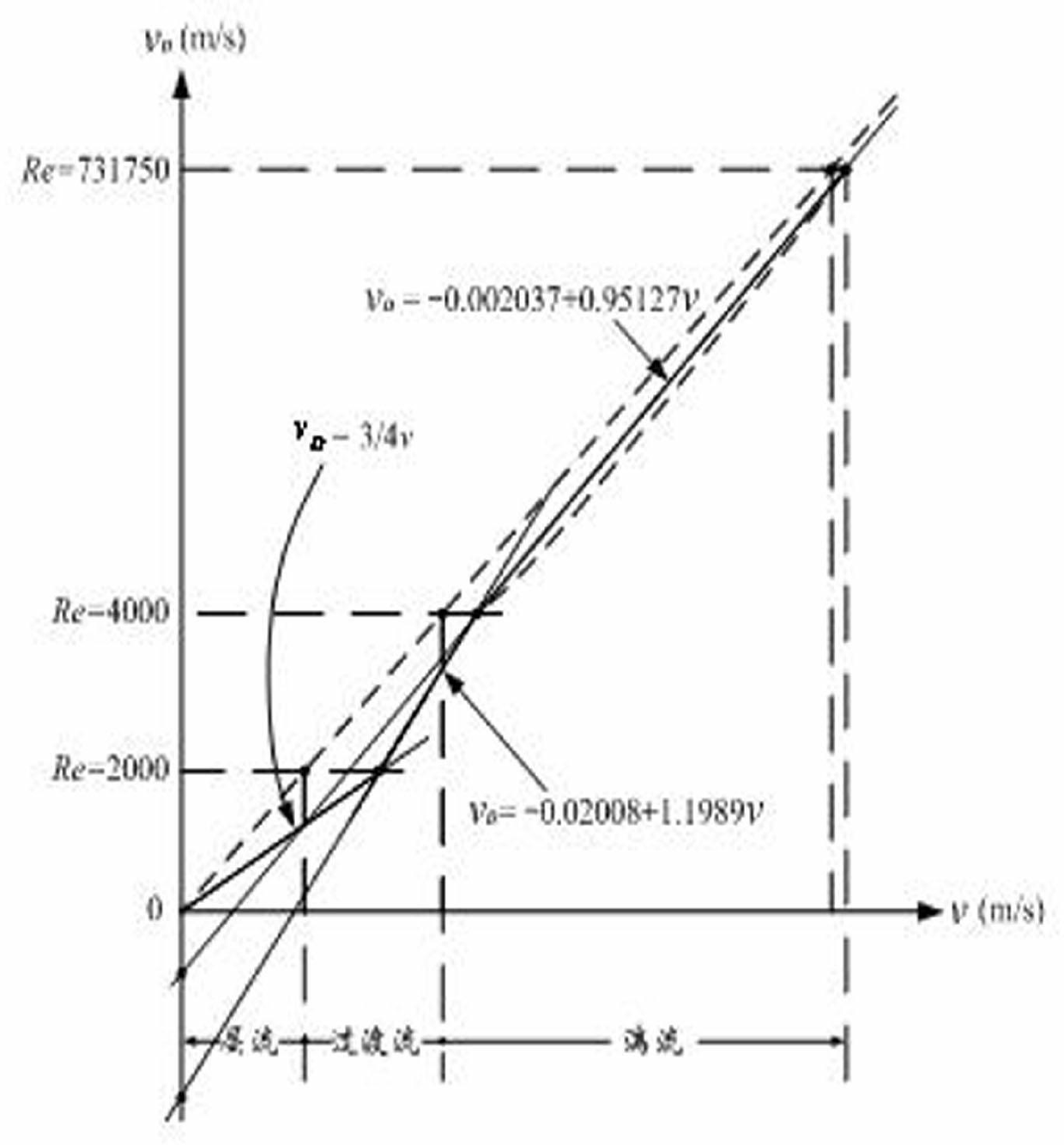

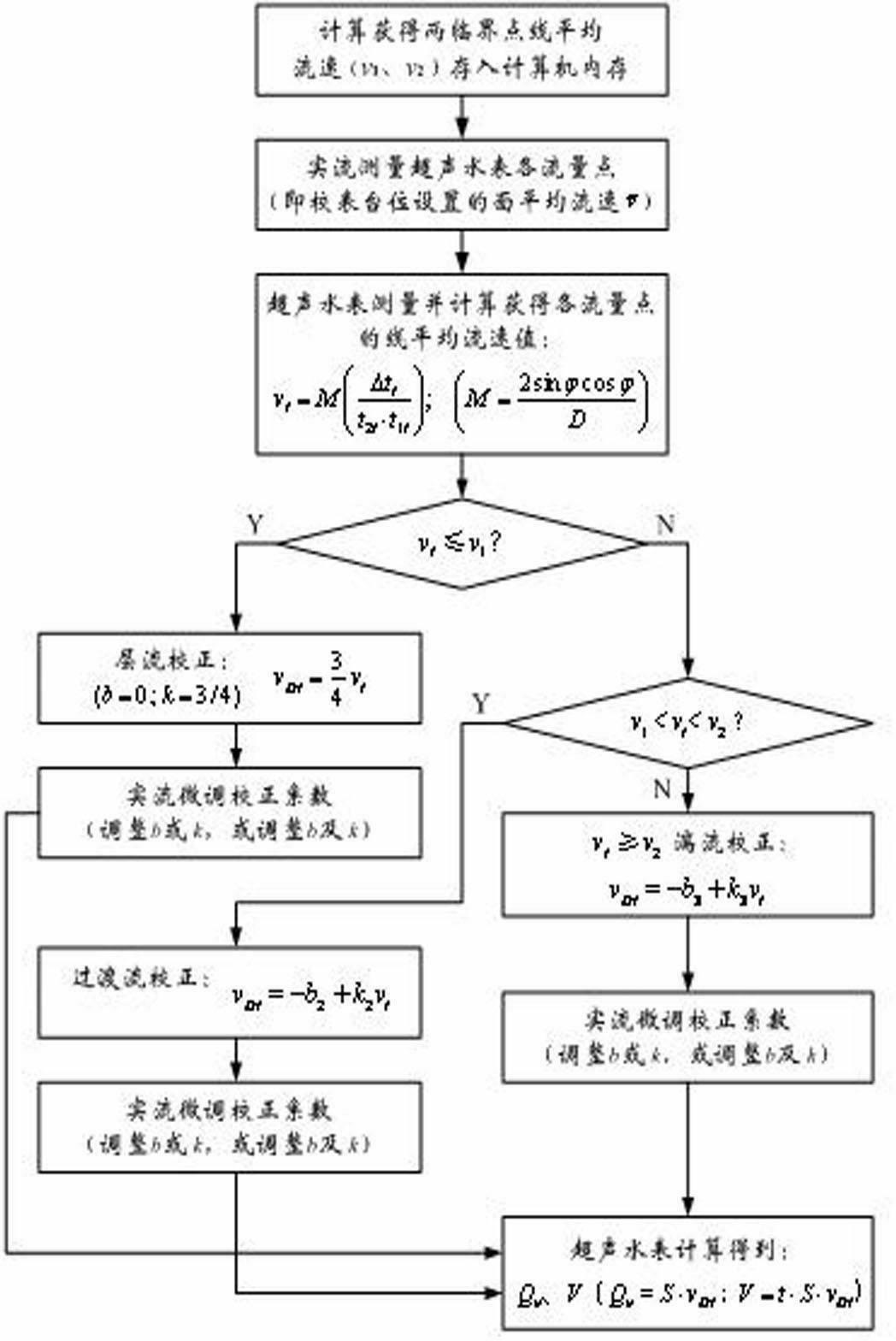

[0018] Set the upper limit of the laminar flow zone ( Re 1 =2000) and the lower limit of the turbulence zone ( Re 2 =4000) are the two demarcation points of the velocity distribution, the corresponding linear average velocity demarcation value is: V 1 , V 2 .

[0019] Take it now: , ;A known: ; ; ; and so: ; In the laminar flow zone, because the surface average velocity and the linear average velocity meet the following relationship: .

[0020] So the average velocity of the dividing point line V 1 for: .

[0021] Similarly, in the turbulence zone: .

[0022] also because: .

[0023] So the average velocity of the dividing point line V 2 for: .

[0024] Will V 1 , V 2 Stored in the memory of the embedded computer of the ultrasonic water meter.

[0025] At the beginning of calibration, use a standard calibration platform to perform real-flow measurement and calibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com