Method for Preparing Prefabricated Fractures in Hydraulic Fracturing Simulation Test Specimen

A technology of hydraulic fracturing and test pieces, applied in teaching models, educational tools, instruments, etc., can solve the problems of high cost, difficulty in obtaining rock cores, and difficulty in meeting size requirements, so as to improve accuracy, increase similarity and The effect of controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

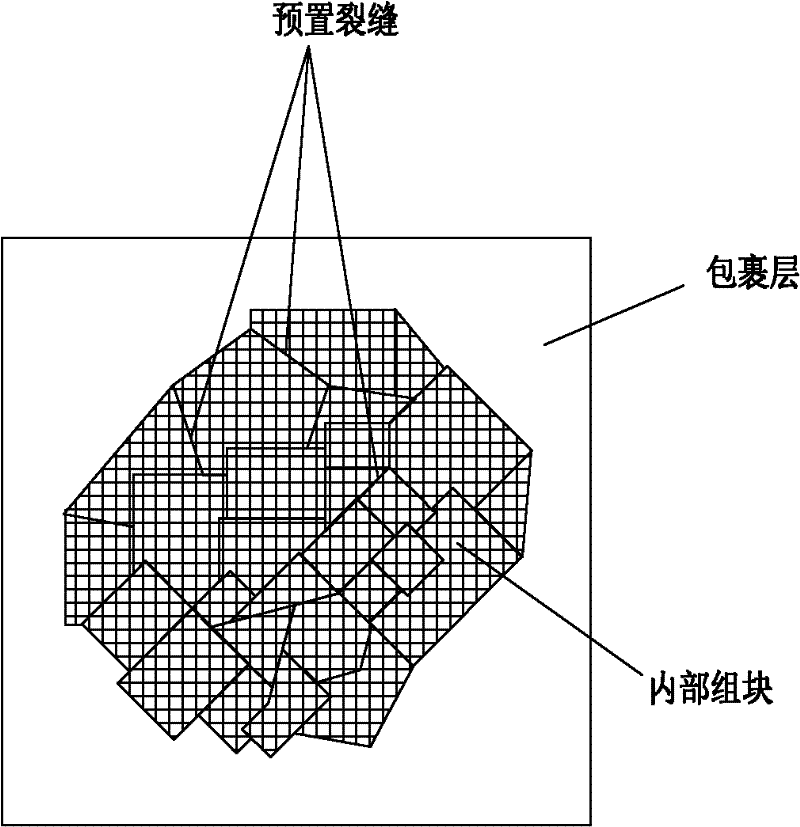

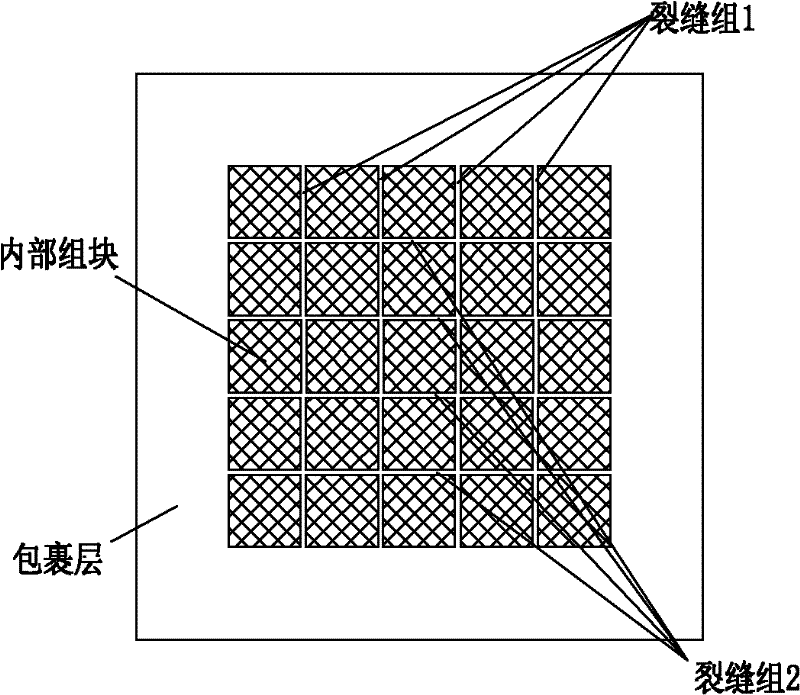

[0032] The present invention proposes a method for preparing pre-set cracks in a hydraulic fracturing simulation test piece, the simulation test piece is composed of a plurality of internal blocks spliced together; the method comprises the following steps:

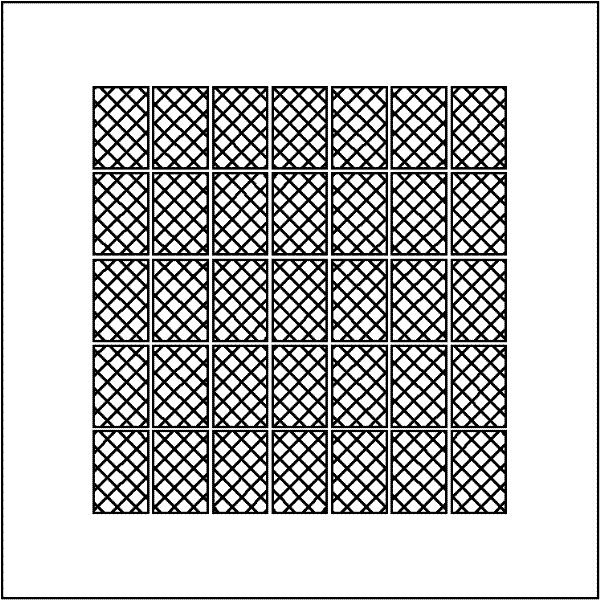

[0033] A) Determine the size, shape and mutual position of each internal block in the simulated test piece according to the fracture morphology characteristics of the stratum to be simulated; make the internal block mold according to the size and shape of each internal block; select the casting material to cast the internal block piece;

[0034] B) Assembling and combining each internal block according to the mutual position, the contact surface between each internal block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com