Directable nozzle for rock drilling bits

a drilling bit and direct-type technology, applied in the field of drilling bits, can solve the problems of reducing the penetration rate, redrilling cuttings, and applying a high compressive load to the rock by the teeth or carbide insert, so as to and prevent excessive nozzle angularity. resulting in inefficient hydraulic performance of the drill bit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

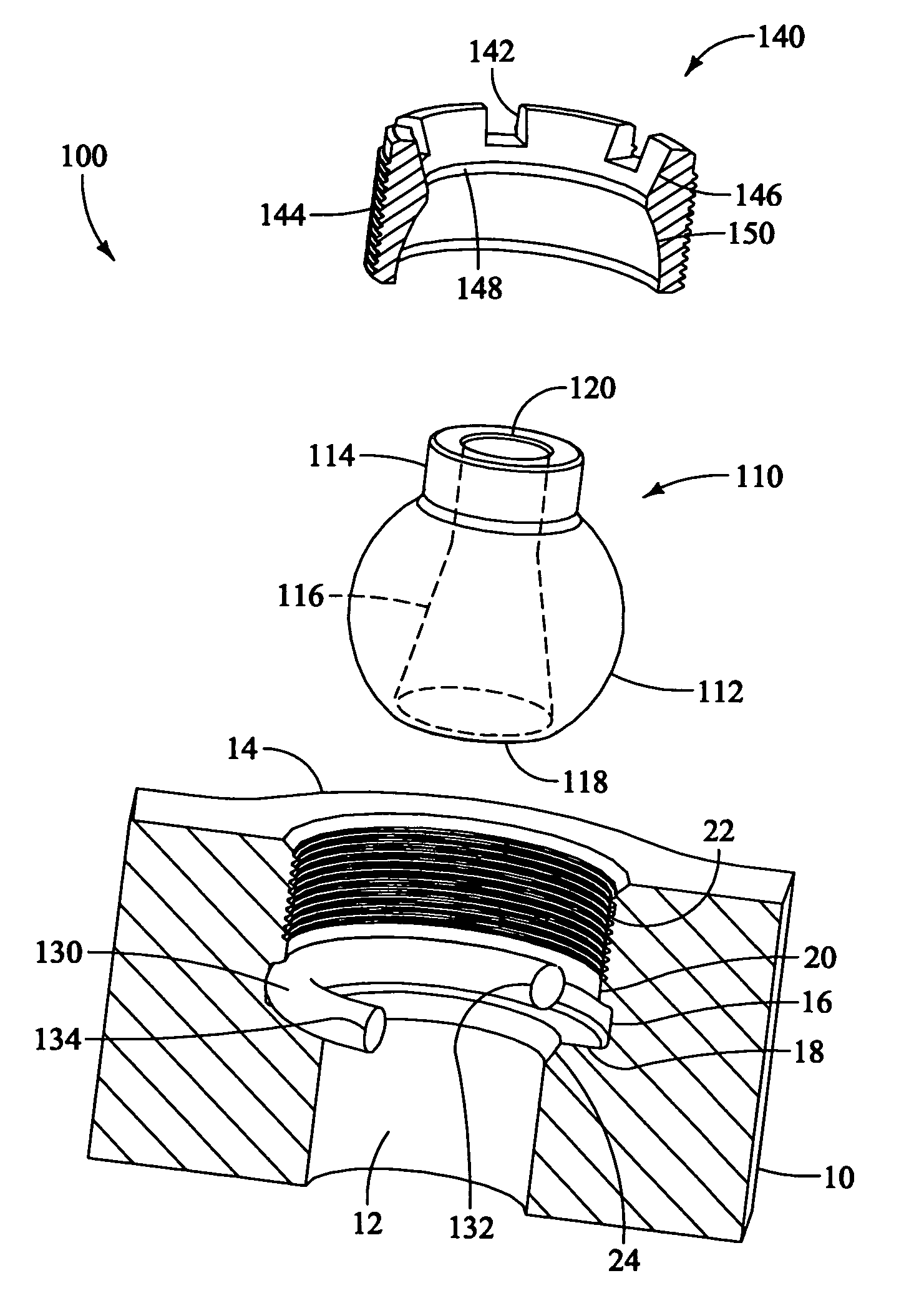

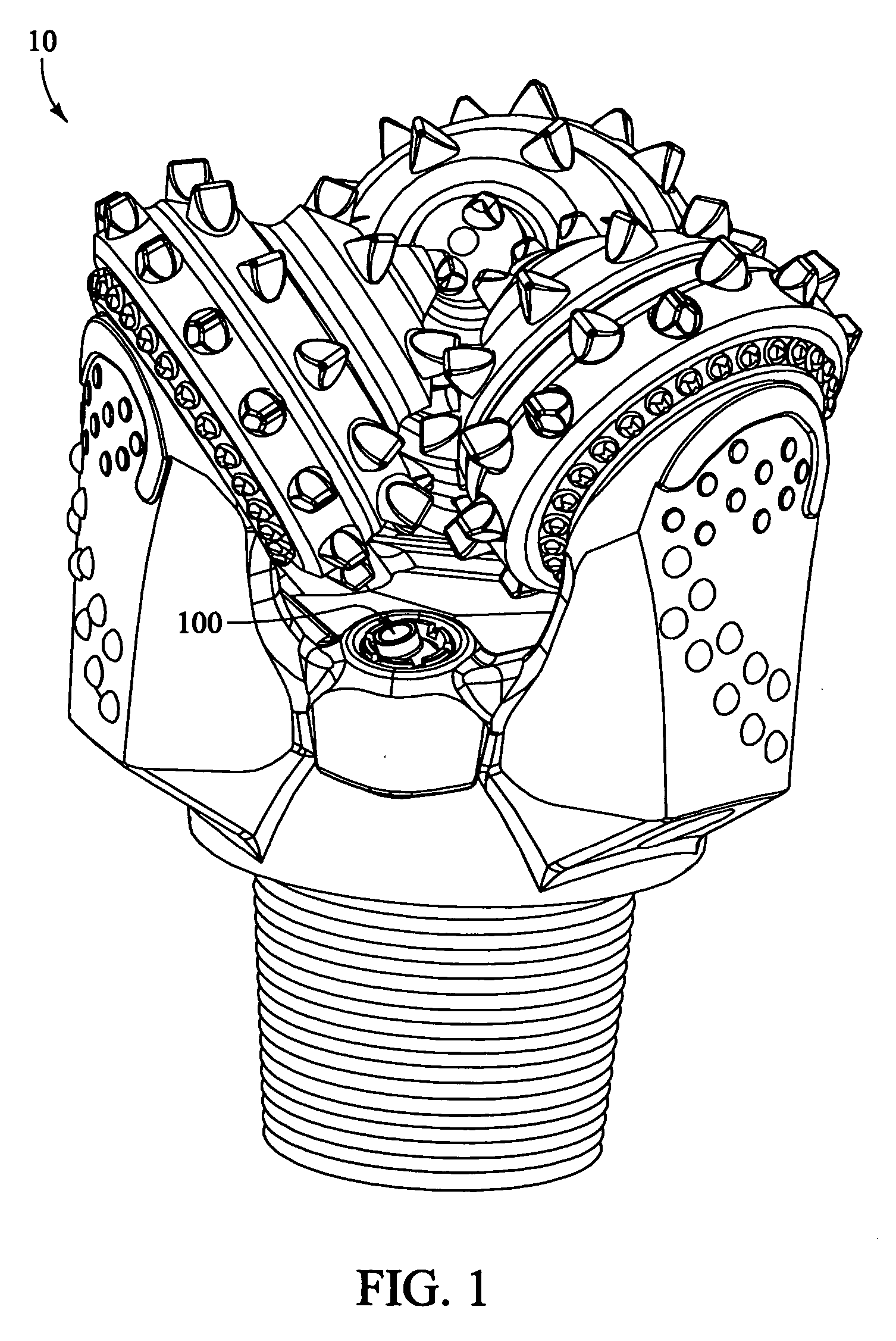

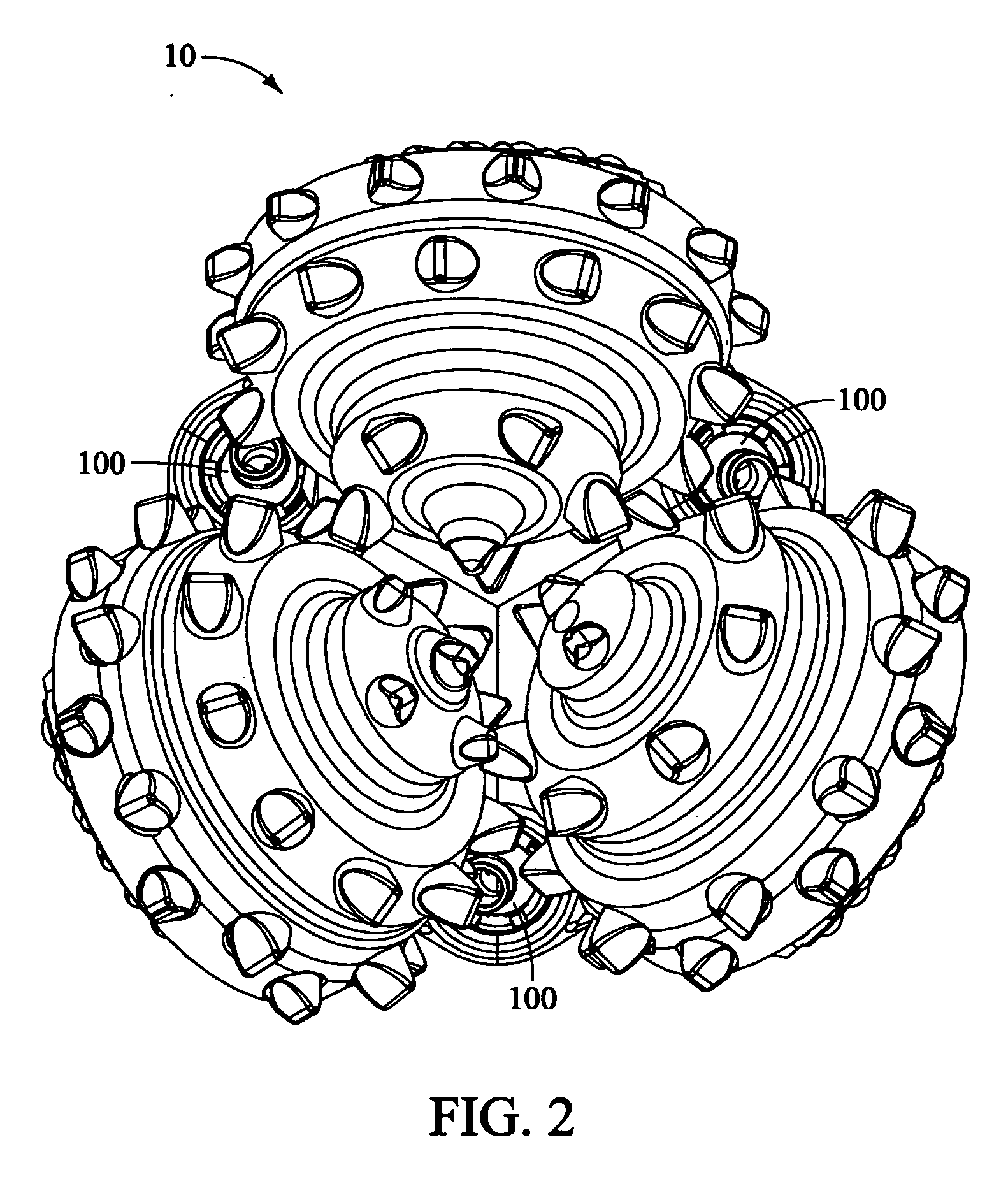

[0039]FIG. 1 is an isometric view of a rotary drill bit 10 having a directable nozzle assembly 100 installed in accordance with a preferred embodiment of the present invention. FIG. 2 is a top view of rotary drill bit 10 of FIG. 1, illustrating multiple directable nozzle assemblies 100 installed in accordance with a preferred embodiment of the present invention.

[0040]FIG. 3 is a side-sectional view of a known art interchangeable nozzle assembly 200 installed in a nozzle boss 14 of rotary drill bit 10. In the view, it is seen that a nozzle 210 is non-directable. Nozzle 210 is secured in fixed alignment with a flow port 12 in rotary drill bit 10. A seal 130 is located in a groove 16 to prevent drilling fluid from bypassing nozzle 210. Drilling fluid passes through flow port 12 of rotary drill bit 10 and then through a nozzle passage 216 of nozzle 210. The drilling fluid enters a first portal 218 and exits a second portal 220, which is significantly smaller in diameter than first port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com