High temperature insulating mould coating

A thermal insulation coating, high temperature technology, applied in fire retardant coatings, polyamide coatings, coatings, etc., can solve the problems of easy cracking, high temperature coatings are not easy, affect adhesion, etc., to achieve enhanced hardness, low viscosity, good flow sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

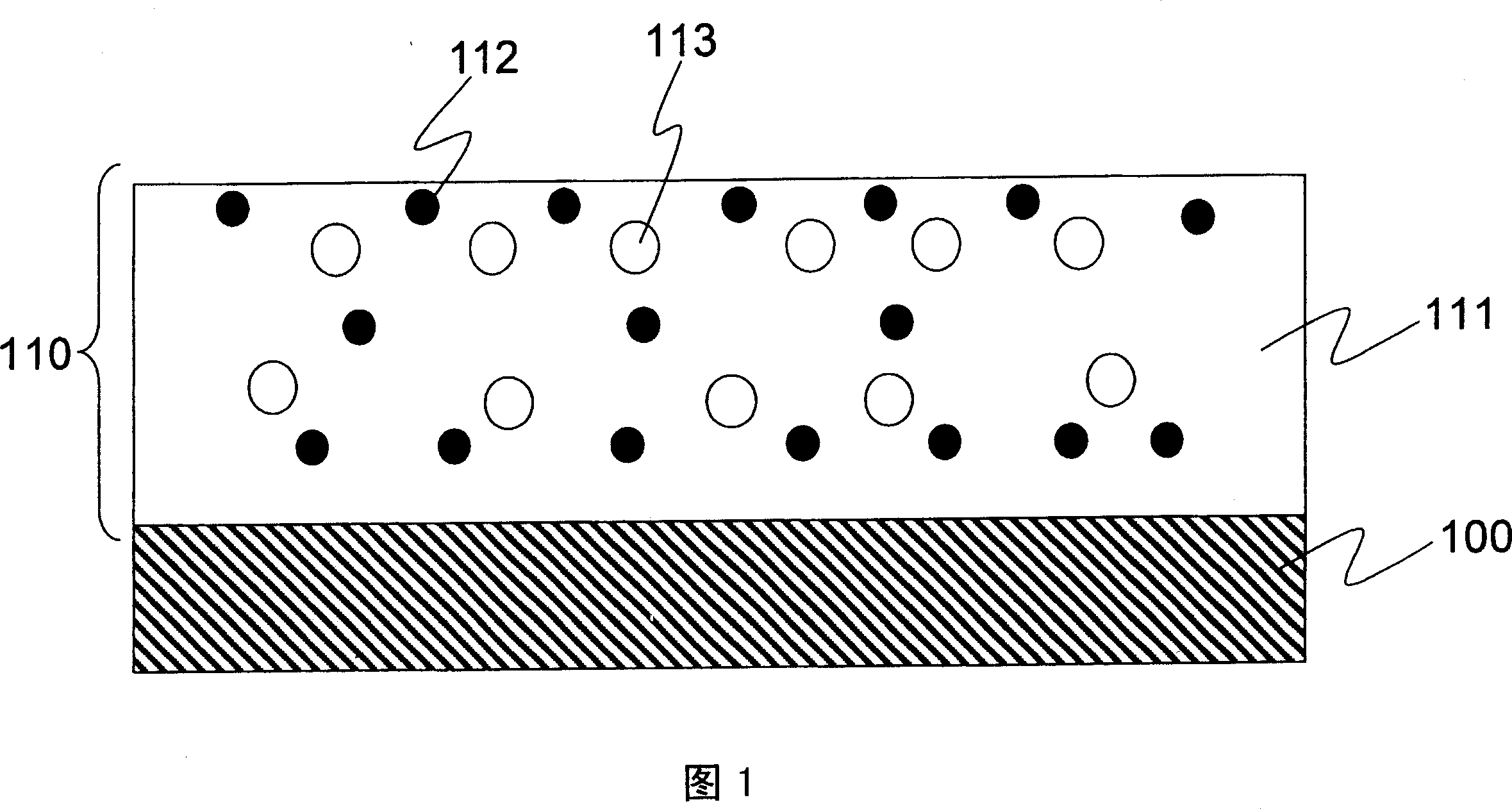

[0028] The high-temperature heat-insulating coating provided by the present invention mainly includes 40wt% to 50wt% heat-resistant resin, 3wt% to 8wt% solvent, 10wt% to 20wt% nanoporous filler and 20wt% to 30wt% hollow microsphere inorganic filler things. The heat-resistant resin contains more than one heat-resistant polymer, the nanoporous filler has a nanoporous structure, and the hollow microsphere inorganic filler is a hollow spherical body, and its special structure can effectively reflect incident light.

[0029] In terms of material selection, heat-resistant resins that can withstand different temperatures can be selected according to the needs of the use environment. Generally, thermosetting resins are better. For example, select ionomers, poly-1-butene, 1,2-butadiene, polystyrene, propylene-styrene resin, propylene-butadiene-styrene resin, poly-p-methylstyrene, butadiene Diene-styrene block polymer, styrene isoprene block polymer, styrene-methyl methacrylate block p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com