High-gravity-center and super-hemisphere multi-attachment polishing device

A polishing device and super-hemisphere technology, applied in the direction of grinding drive device, grinding/polishing equipment, machine tool with surface polishing, etc., can solve the problem of unqualified super-hemisphere with high center of gravity, etc., and achieve the effect of convenient grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

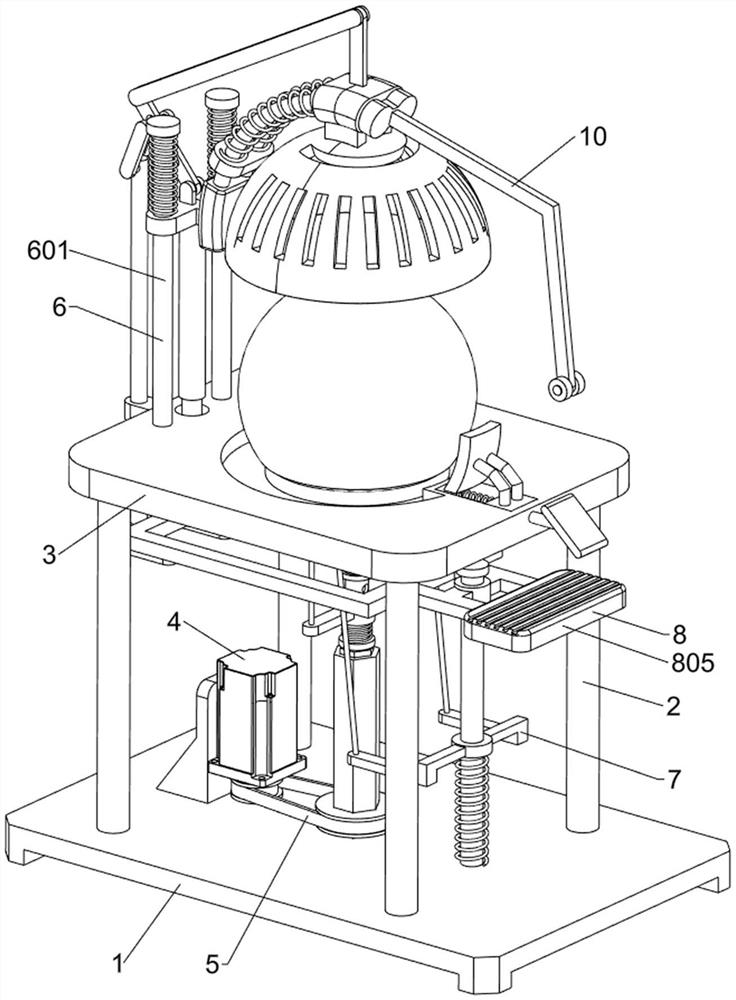

[0061] A high center of gravity and hyper-hemispheric multi-paste polishing device, such as figure 1 As shown, it includes a base plate 1, a support rod 2, a workbench 3, a ball 301, a servo motor 4, a drive assembly 5, a polishing assembly 6 and a rotating assembly 7. The support rods 2 are arranged symmetrically on both sides of the top of the base plate 1. A workbench 3 is connected between the tops of the poles 2, and a plurality of balls 301 are rotated in the middle of the top of the workbench 3. A servo motor 4 is provided on the left side of the top of the bottom plate 1, and a servo motor 4 is connected between the output shaft of the servo motor 4 and the top of the bottom plate 1. Drive assembly 5, polishing assembly 6 is provided on the top left side of workbench 3, and rotating assembly 7 is provided on the top right side of bottom plate 1.

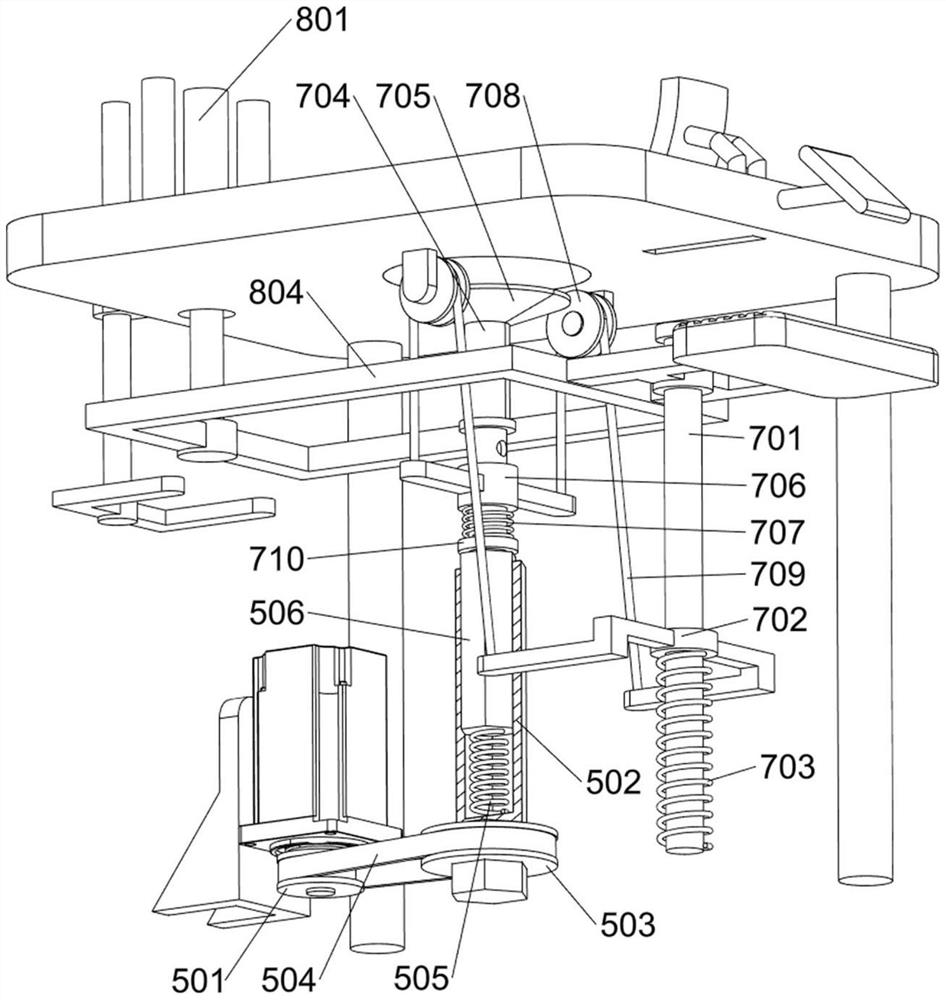

[0062] Such as figure 2 and image 3 As shown, the driving assembly 5 includes a first transmission wheel 501, an inner ...

Embodiment 2

[0067] On the basis of Example 1, such as image 3 and Figure 4 As shown, it also includes a stepping assembly 8, the stepping assembly 8 includes a first set of rods 801, a movable rod 802, a sixth spring 803, a connecting frame 804 and a pedal 805, the bottom of the slider 602 is provided with a first set of rods 801, the second A sliding type is provided with movable rod 802 in a set of rods 801, the sixth spring 803 is connected between the top of movable rod 802 and the inner wall of the first set of rods 801, and the upper side of guide rod 701 is slidingly provided with connecting frame 804, and the top of connecting frame 804 is left The side is connected with the bottom of the movable rod 802, and the right end of the connecting frame 804 is provided with a pedal 805.

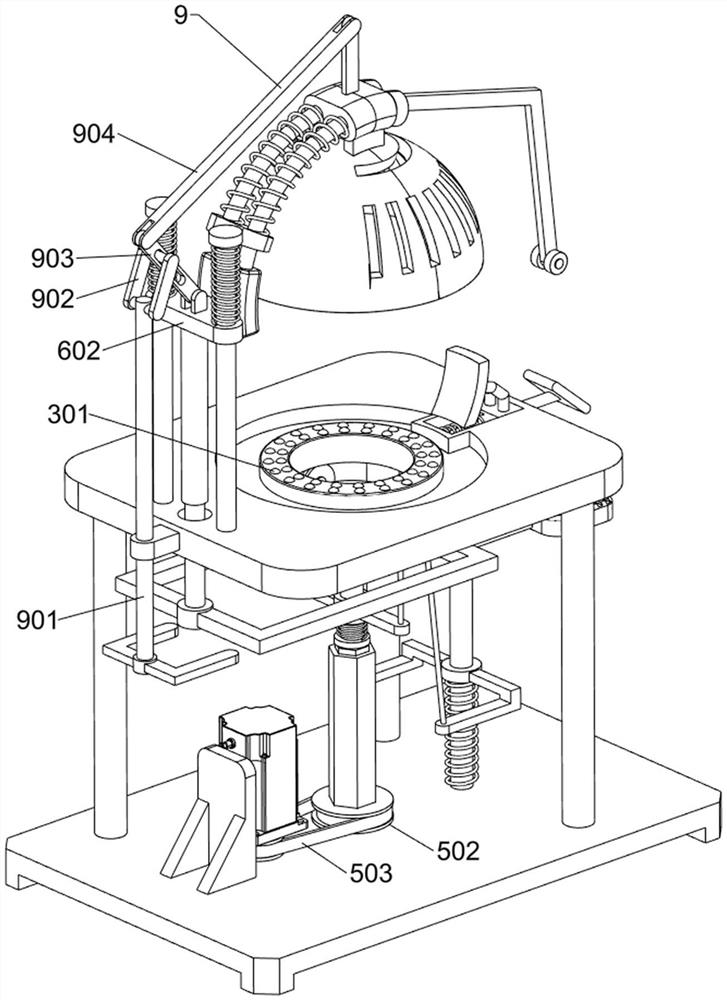

[0068] Such as figure 2 As shown, a rotating assembly 9 is also included. The rotating assembly 9 includes a first slide bar 901, an N-shaped bar 902, a rotating bar 903 and a connecting rod 904. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com