Crystal ball face milling machine

A crystal ball and surface grinding machine technology, which is applied to spherical surface grinders, grinders, grinding/polishing equipment, etc., can solve the problem that the crystal blank clamping mechanism cannot change the relative position according to the processing requirements, the aluminum row positioning and clamping is time-consuming and laborious, and the crystal blank The range of the ball grinding surface becomes smaller and other problems, so as to increase the range of the grinding surface rotation angle, the structure is simple, and the torque shortage is solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

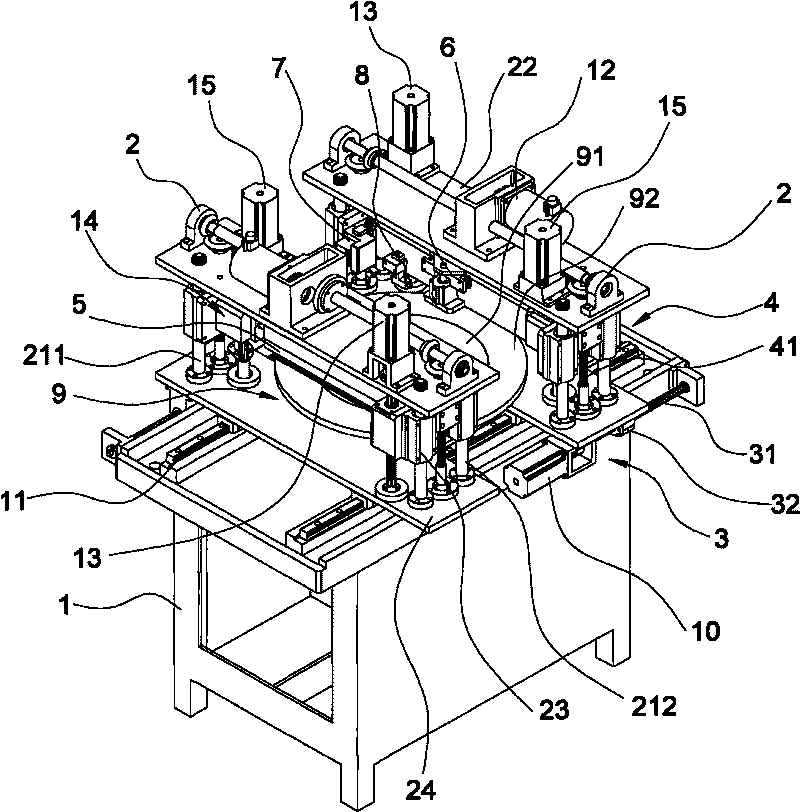

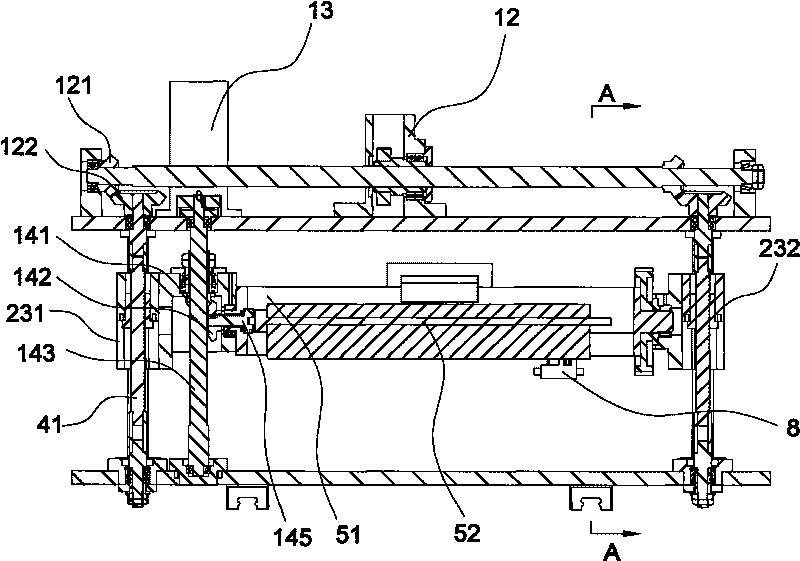

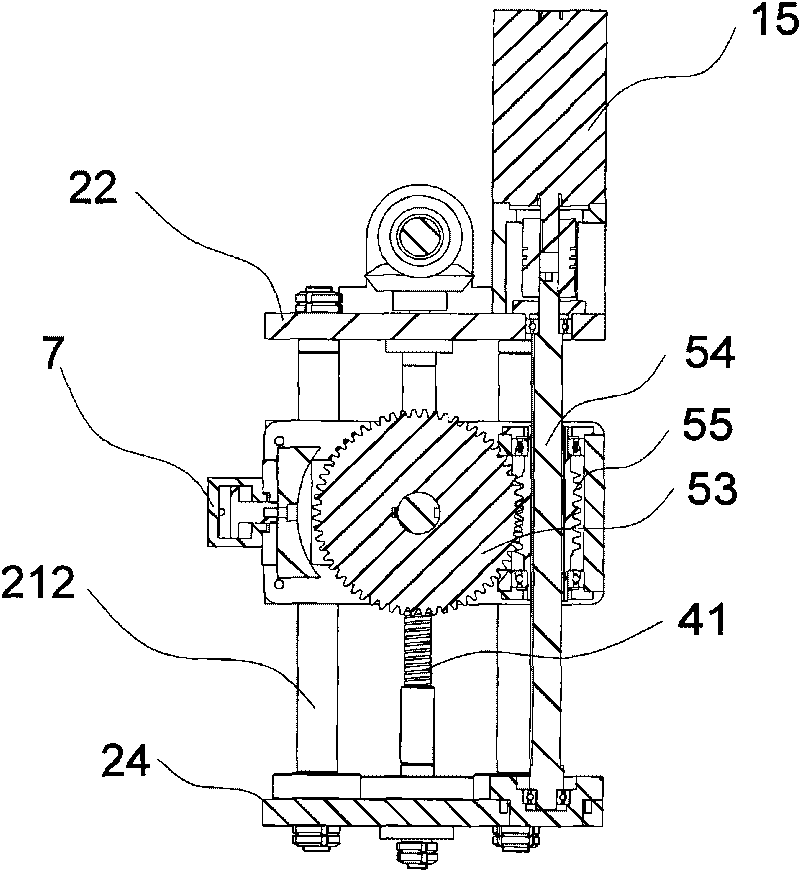

[0026] Such as figure 1 with figure 2 As shown, a crystal ball grinding machine of the present invention includes a frame 1 and a grinding disc mechanism 9 arranged on the frame 1, and is arranged on the frame 1 and can slide horizontally along the slide rail 11 on the frame 1. A pair of center-symmetrically distributed carriage mechanisms 2 matched with the grinding disc mechanism 9. On the carriage mechanism 2, an aluminum row 5 is fixed on the carriage mechanism 2 by an automatically clamped movable dovetail fixture 6, which corresponds to the carriage mechanism on the frame 1. The frame mechanism 2 is provided with two horizontal moving mechanisms 3, the horizontal moving mechanism 3 allows the corresponding towing frame mechanism 2 to move independently in the horizontal direction on the frame 1, and the towing frame mechanism 2 is provided with a vertical moving vertical Straight moving mechanism 4. The carriage mechanism 2 includes a left cylindrical guide rail 211 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com