Digital controlled sperical grinding machine having auto detection

A spherical grinding machine, automatic detection technology, applied in the direction of spherical grinding machines, grinding machines, grinding machine parts, etc., can solve the problems of large measurement errors, affecting the processing accuracy of workpieces, manual measurement, etc., and achieve small measurement errors and high processing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Now further describe the technical solution of the present invention in conjunction with the accompanying drawings and embodiments.

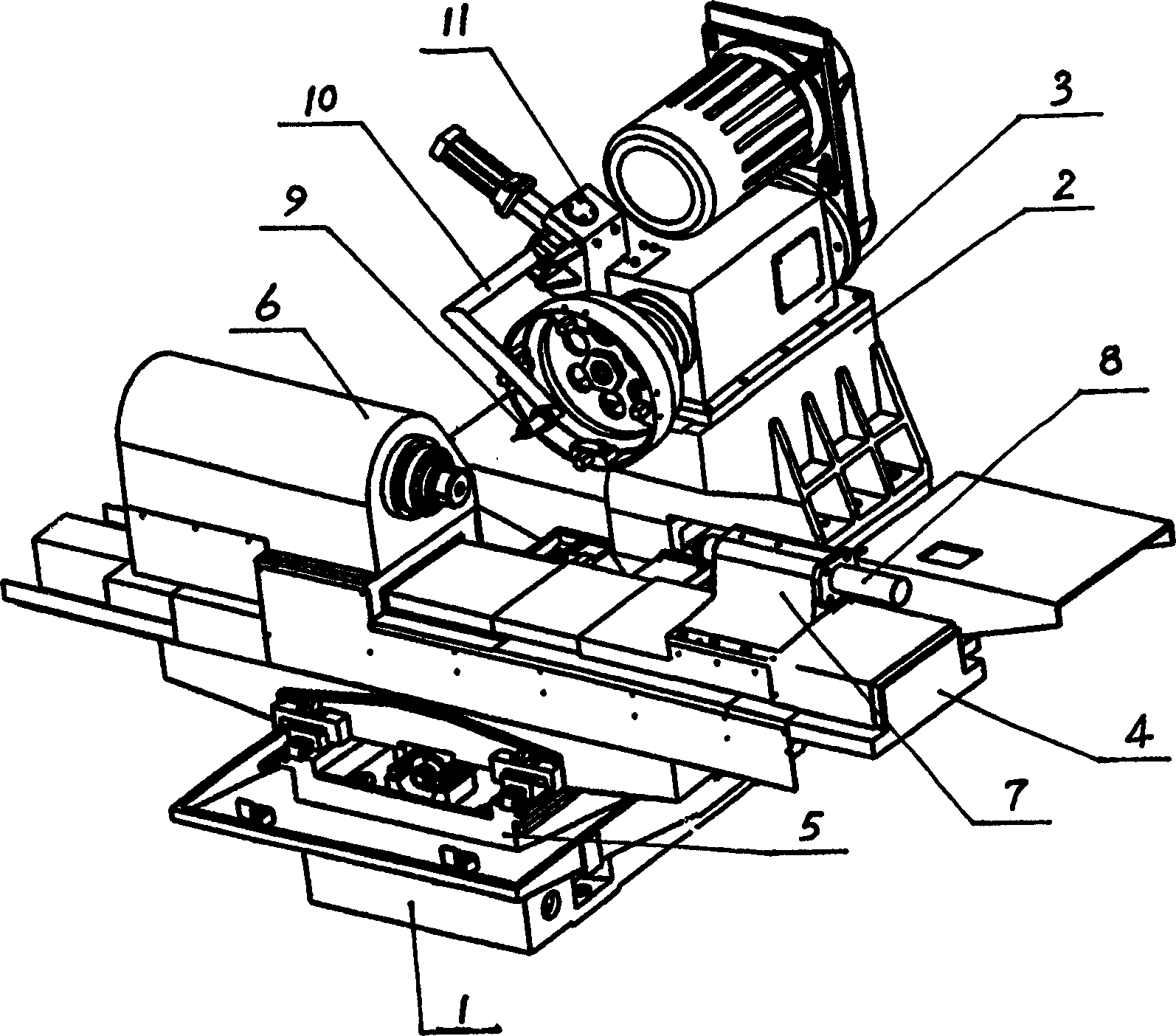

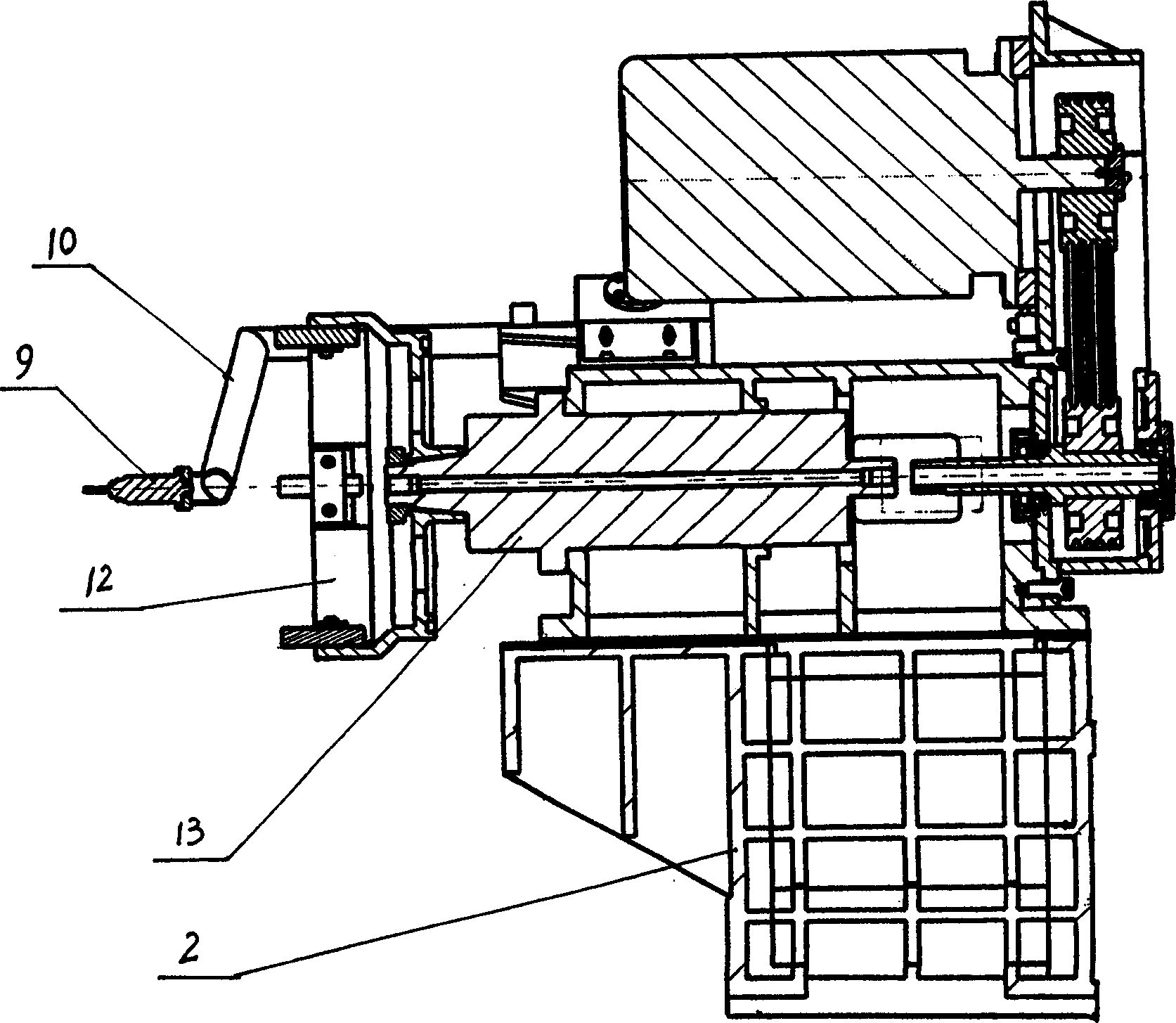

[0010] Such as figure 1 The structure of the automatic detection CNC spherical grinding machine shown includes a base 1, a bed body 2, a feeding mechanism, a workpiece clamping mechanism, a grinding head mechanism 3, a hydraulic system, and a numerical control system. The feeding mechanism adopts a cross-sliding saddle structure. The upper sliding plate 4 carries the workpiece clamping mechanism for X-direction movement to complete the alignment between the center of the ball and the center of the grinding head spindle. The sliding saddle 5 carries the upper sliding plate 4 for Z-direction movement to complete the feed movement of the workpiece. . The movement of the X and Z axes of the machine tool is realized by AC servo motors driving precision ball screw pairs. The workpiece clamping mechanism includes a headstock mechanism 6 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com