Flat-bulb steel ultrasonic automatic flaw detection device and flaw detection method

A flaw detection device, the technology of bulb flat steel, which is applied in measurement devices, analysis of solids using sonic/ultrasonic/infrasonic waves, and material analysis using sonic/ultrasonic/infrasonic waves, etc. Symmetrical bulb flat steel output and other issues, to achieve the effect of improving labor productivity and realizing online automatic detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

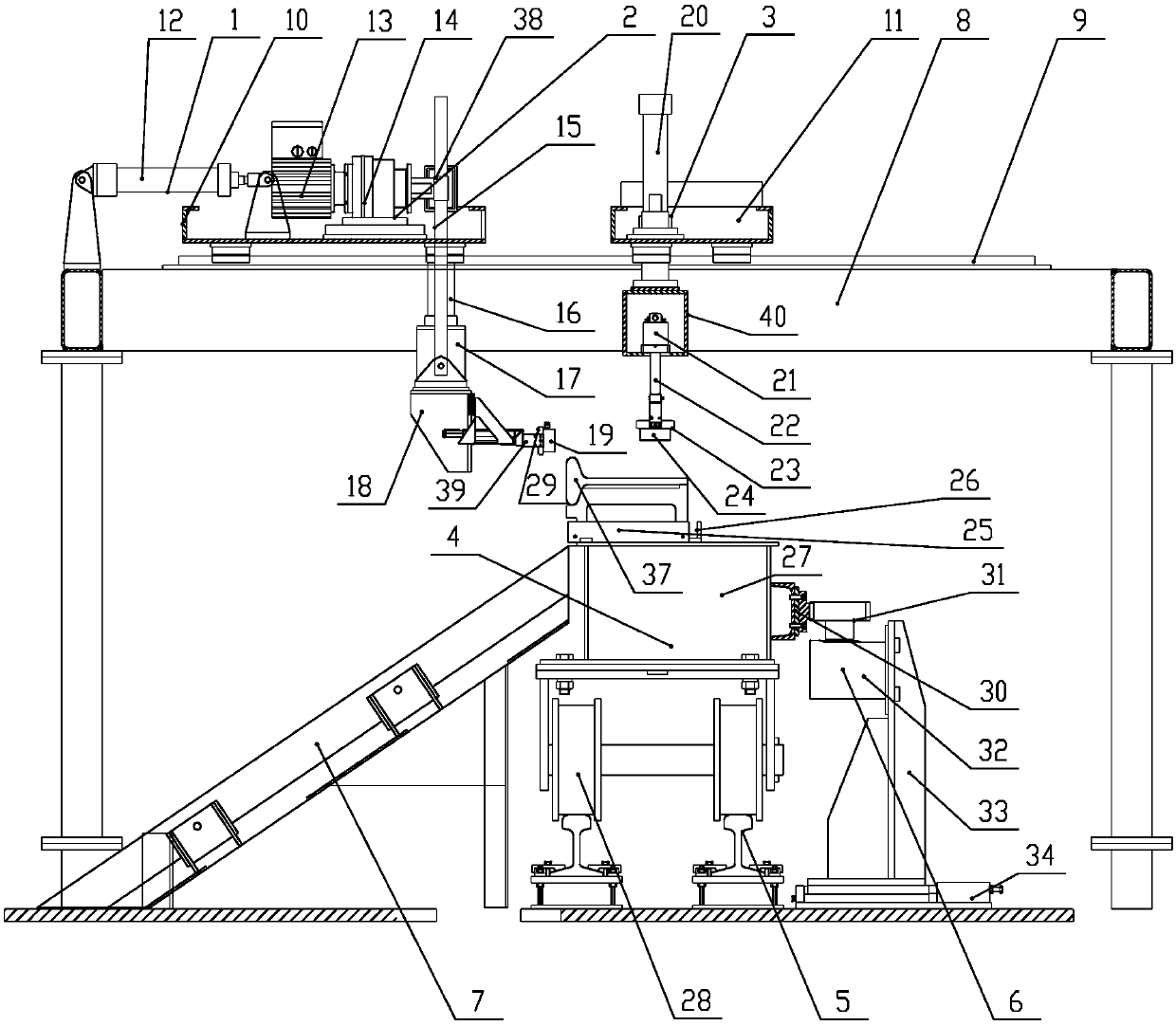

[0037] Such as Figure 2-8 Shown, based on the flaw detection method of the bulb flat steel ultrasonic automatic flaw detection device. Double-head flat steel 37 and sphere 35 detection adopts 6-channel symmetrical ball head two-way simultaneous scanning, and web 36 detection adopts 8-channel overlapping and covering scanning, which specifically includes the following steps:

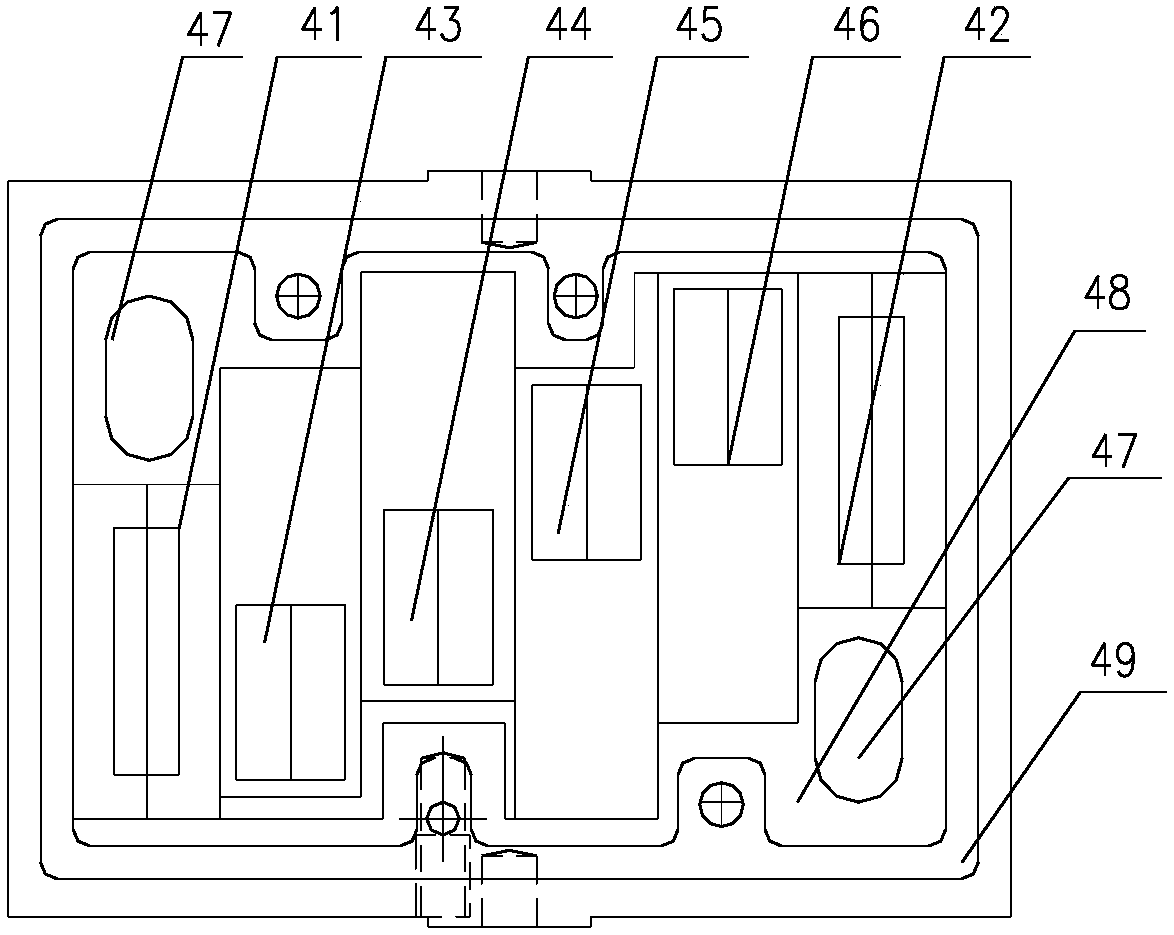

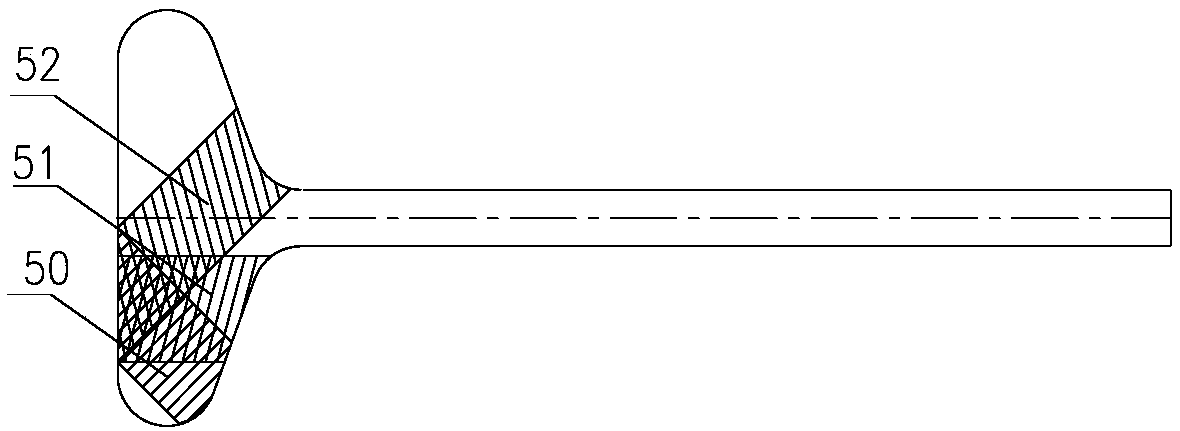

[0038] 1) Arrange an 8-channel combined ultrasonic probe on the web 36 of the double-headed spherical flat steel 37, where the probe 53 at the 1st position of the web, the probe 54 at the 2nd position of the web, the probe 55 at the 3rd position of the web, and the 4th position of the web The number probe 56 is a 4P 30×5FG8Z double-precision straight probe arranged longitudinally; the web number 5 probe 57, the web number 6 probe 58, the web number 7 probe 59, and the web number 8 probe 60 are horizontal 4P 30×5FG8Z double-precision straight probes are arranged, the hard alloy wear-resistant block 47 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com