Binding machine with buckling-free steel belt

A technology of strapping machine and steel belt, which is applied to the parts of strapping machinery, strapping materials, paper/cardboard containers, etc., which can solve the problems of large volume and inability to bind materials tightly, and achieve the effect of saving locks and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention are now further described in conjunction with the accompanying drawings:

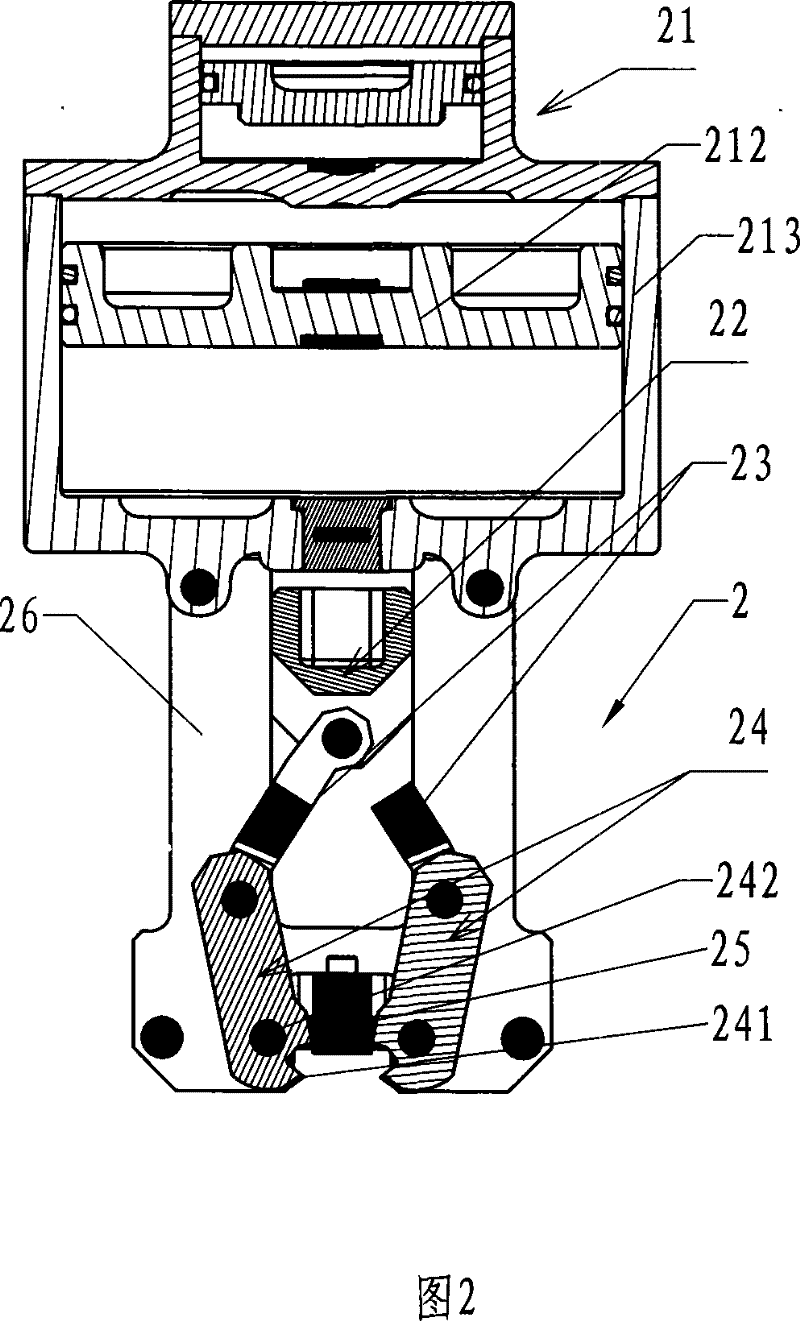

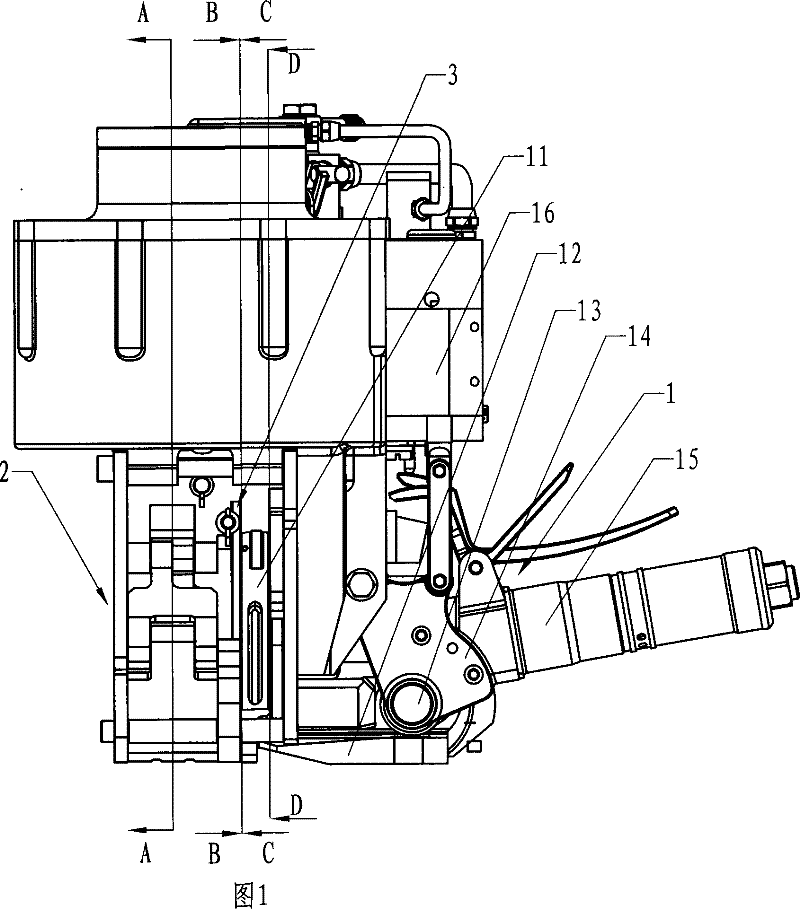

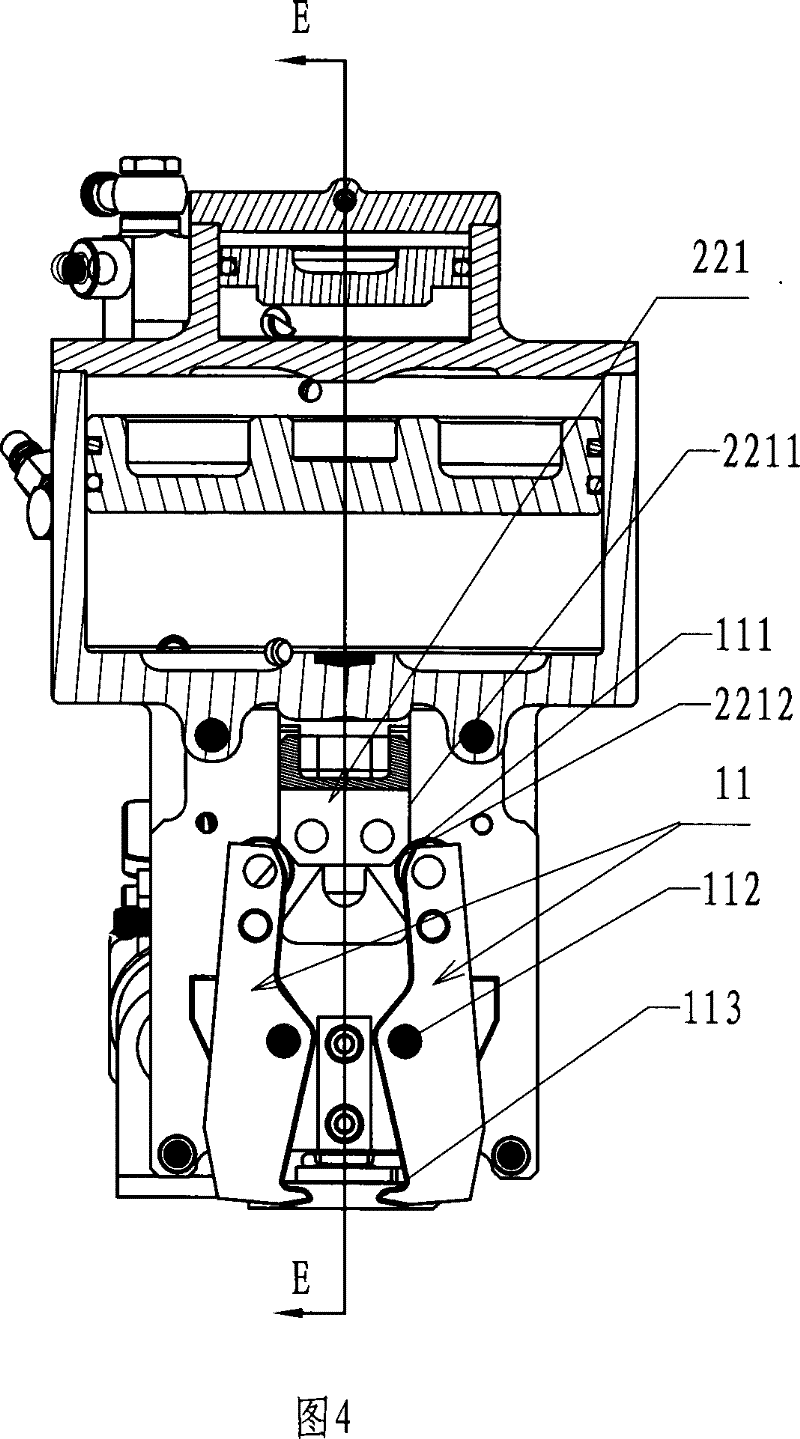

[0019] Such as figure 2 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 As shown, an embodiment of a buckle-free steel strip binding machine of the present invention includes a steel strip tensioning mechanism 1, a press-lock steel strip mechanism 2 and a steel strip cutting mechanism 3, wherein the press-lock steel strip mechanism 2 is located at the steel strip cutting In front of the mechanism 3, the steel strip cutting mechanism 3 is located in front of the steel strip tensioning mechanism 1; the steel strip tensioning mechanism 1 includes a pressing plate 11 on the front side, a tensioning base 12 on the bottom side, and a tensioning base 12 on the bottom side. The tensioning roller 13 and its mounting seat 14 on the upper rear side of the base 12 are positioned at the handle 15 on the rear side, and the handle 15 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com