Pressing type test strip packing box

A packaging box and pressing technology, which is applied in the field of pressing test strip packaging, can solve the problems of test strip contamination, test result error, low efficiency of taking out test strips, etc., and achieve the effect of avoiding pollution and reducing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

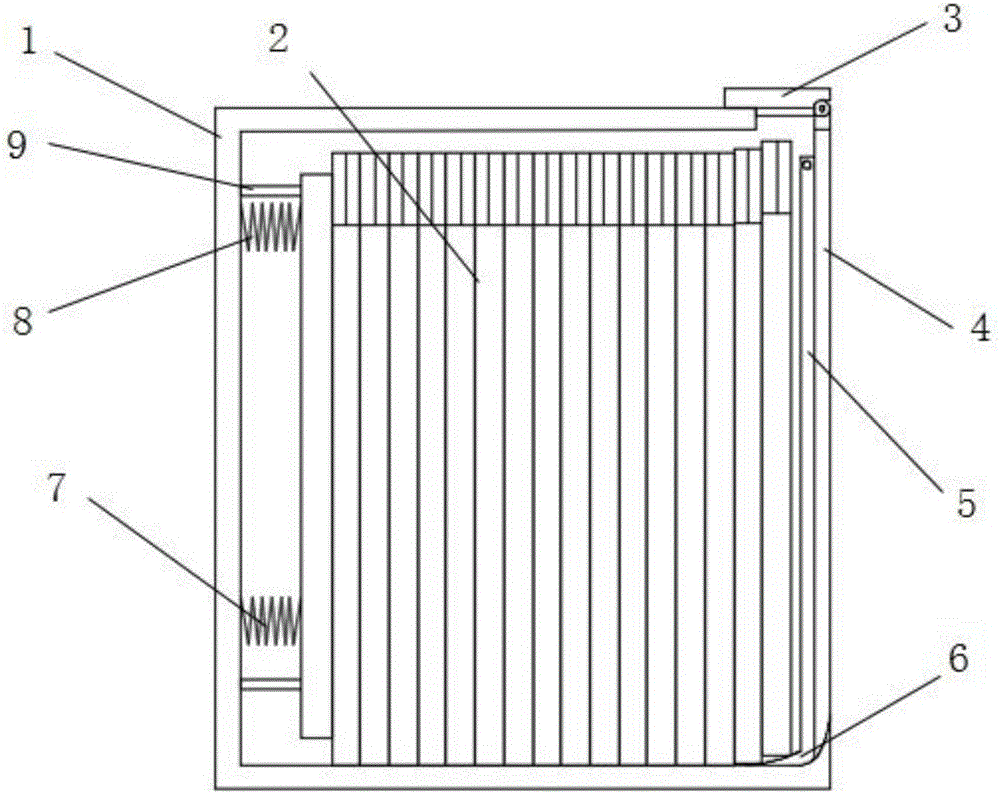

[0018] Embodiment 1: A push-type test strip packaging box, including a box body; the upper end of the right side of the box body is provided with a test strip outlet; the right side of the test strip outlet is provided with a pressing block; the pressing The block is set on the box body through the rotating shaft; the rotating shaft is located at the upper quarter to one tenth of the pressing block; the left side of the box body opposite to the pressing block is provided with an upper spring and a lower spring ; The box is provided with an extrusion block; the upper side spring is connected to the upper end of the inner side of the left side of the box body and the upper end of the extrusion block; the lower side spring is connected to the lower end of the inner side of the left side of the box body and the lower end of the extrusion block ; The test strip is stored between the extruding block and the pressing block; the inner bottom of the pressing block is provided with an ar...

Embodiment 2

[0019] Embodiment 2: A push-type test strip packaging box, including a box body; the upper end of the right side of the box body is provided with a test strip outlet; the right side of the test strip outlet is provided with a pressing block; the pressing The block is set on the box body through the rotating shaft; the rotating shaft is located at the upper quarter to one tenth of the pressing block; the left side of the box body opposite to the pressing block is provided with an upper spring and a lower spring ; The box is provided with an extrusion block; the upper side spring is connected to the upper end of the inner side of the left side of the box body and the upper end of the extrusion block; the lower side spring is connected to the lower end of the inner side of the left side of the box body and the lower end of the extrusion block The test strip is stored between the extrusion block and the pressing block; the inner bottom of the pressing block is provided with an arc-...

Embodiment 3

[0020] Embodiment 3: A push-type test strip packaging box, including a box body; the upper end of the right side of the box body is provided with a test strip outlet; the right side of the test strip outlet is provided with a pressing block; the pressing The block is set on the box body through the rotating shaft; the rotating shaft is located at the upper quarter to one tenth of the pressing block; the left side of the box body opposite to the pressing block is provided with an upper spring and a lower spring ; The box is provided with an extrusion block; the upper side spring is connected to the upper end of the inner side of the left side of the box body and the upper end of the extrusion block; the lower side spring is connected to the lower end of the inner side of the left side of the box body and the lower end of the extrusion block The space between the extruding block and the pressing block is used to store test strips; the bottom of the inner side of the pressing bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com