Steel strip packing car

A technology of baling car and steel belt, applied in the direction of bundling materials, etc., can solve problems such as affecting corporate image, dragging, easy occurrence of different buckles, etc., to achieve the effect of convenient operation for internal employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

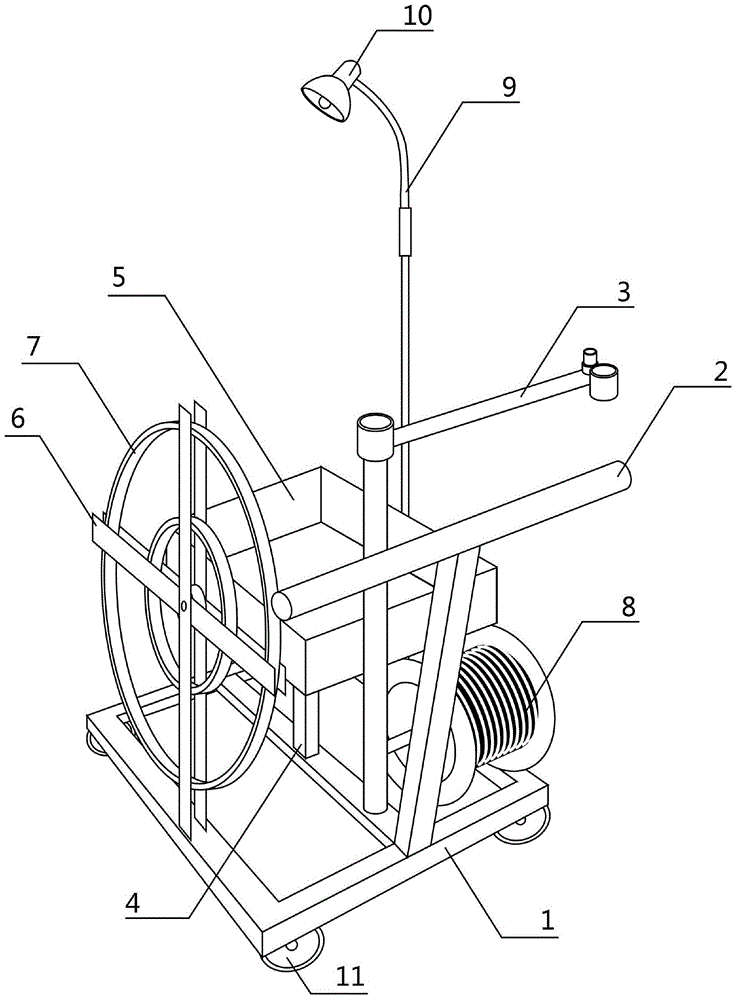

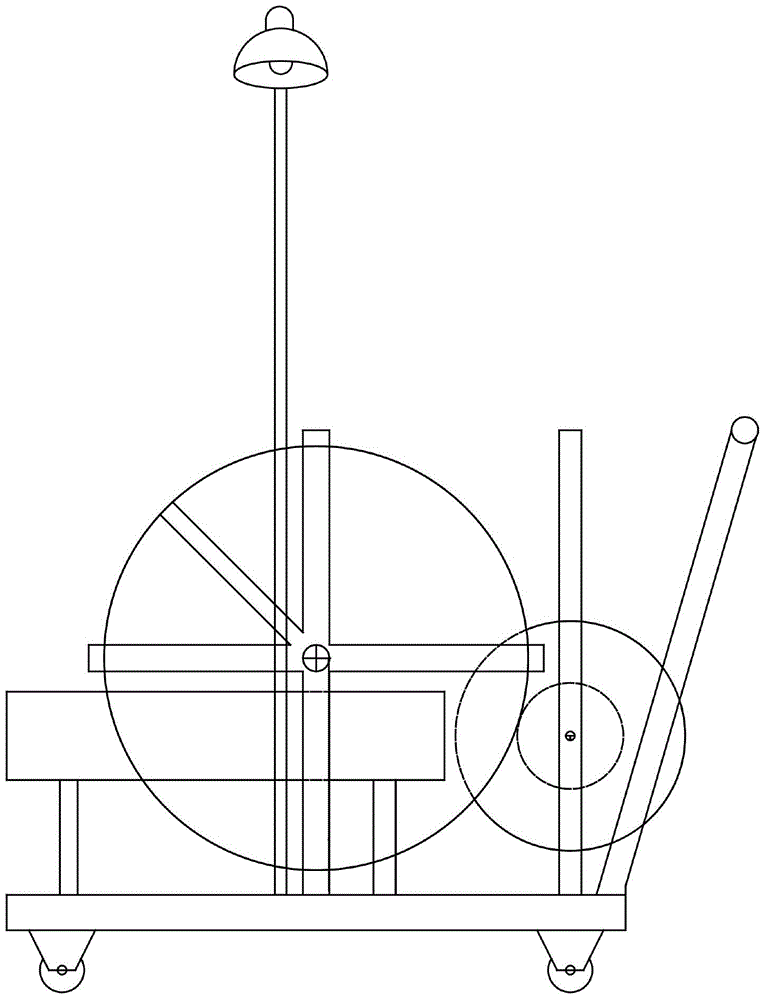

[0016] Such as figure 1 , figure 2 A steel belt packing car shown is characterized in that it consists of a base 1, a push handle 2, an auxiliary tool bar 3, a bottom support frame 4, a packing wheel bracket 6, a cable shaft 8 and a wire groove 9, and the push handle 2 Located on the upper part of one side of the base 1, the push handle 2 is fixedly connected to the base 1, the auxiliary tool rod 3 is located on the upper part of the base 1, the auxiliary tool rod 3 is fixedly connected to the base 1, and the bottom support frame 4 is located on the top of the base 1, the bottom support frame 4 is fixedly connected to the base 1, the packing wheel bracket 6 is located on the top of one side of the base 1, the packing wheel bracket 6 is fixedly connected to the base 1, and the cable The shaft 8 is located on the upper part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com