Full-automatic nylon binding tape cutting and packaging all-in-one machine

A nylon cable tie and all-in-one machine technology, which is applied in packaging, transportation packaging, and packaging protection, can solve problems such as low work efficiency, high molding temperature of nylon cable ties, and poor working environment for operators, so as to reduce labor costs and improve Production quality and work efficiency, the effect of meeting the needs of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in detail below in conjunction with the accompanying drawings.

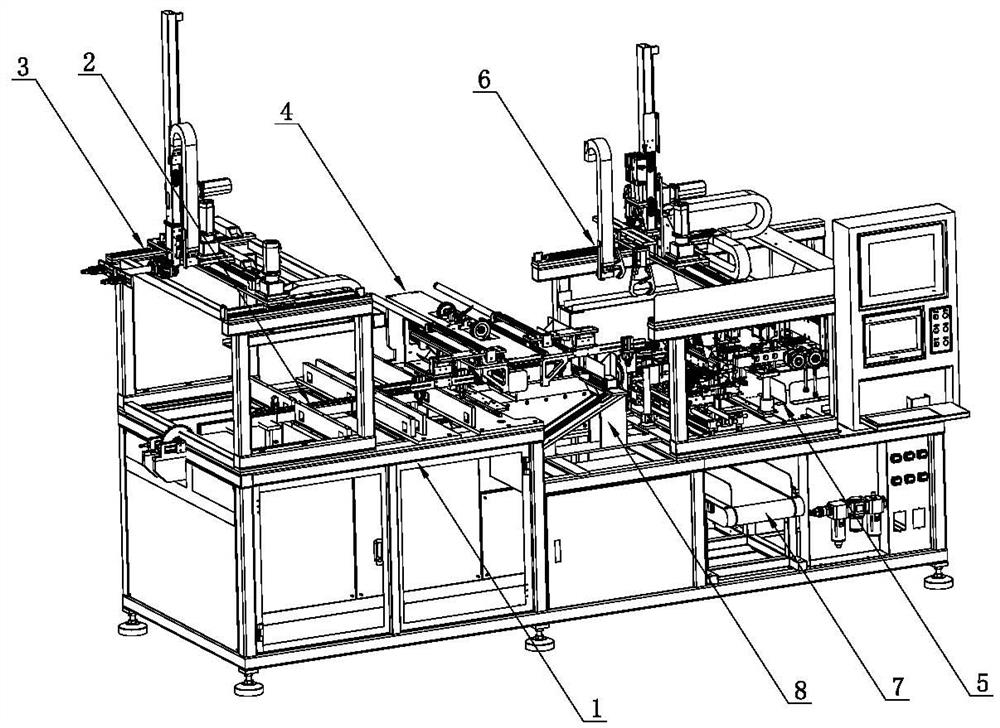

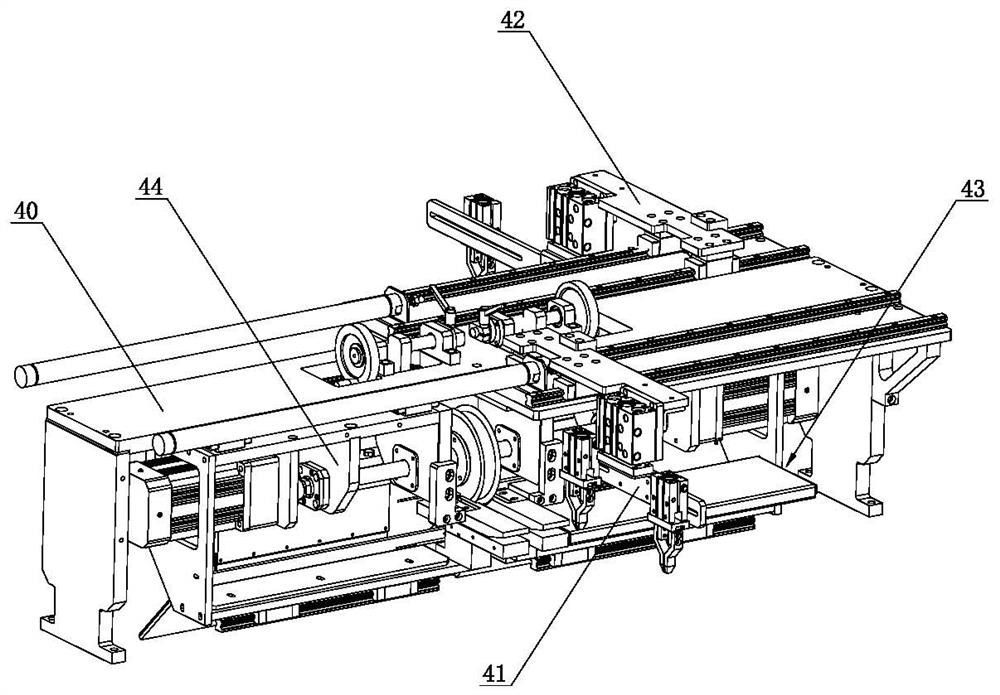

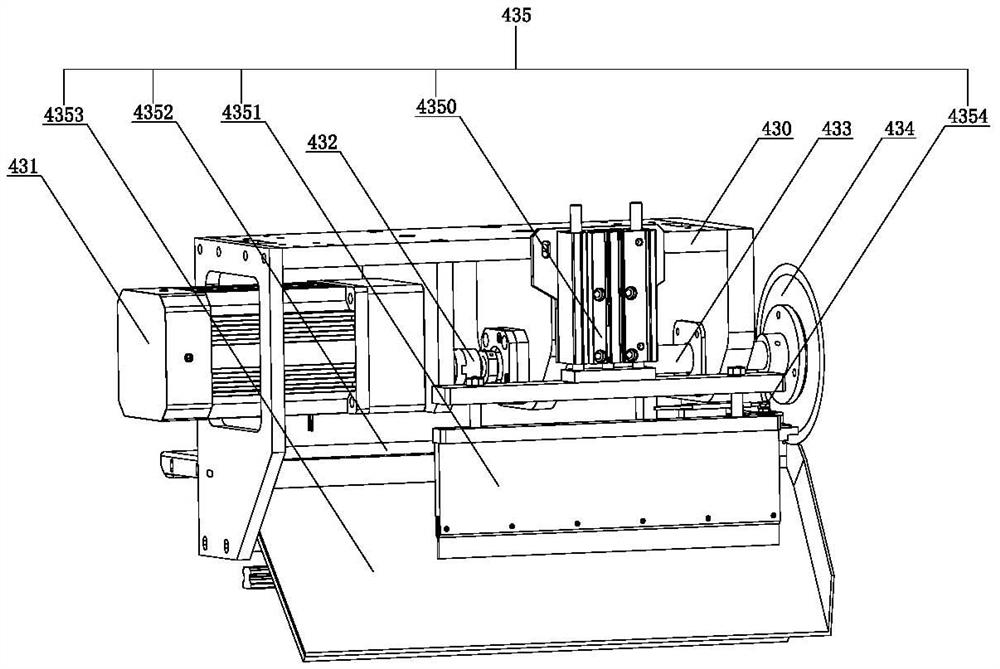

[0062] like Figure 1 to Figure 9 As shown, a fully automatic nylon cable tie cutting and packaging machine of the present invention includes a frame 1, and the frame 1 is laterally provided with a feeding conveyor belt 2 for transporting nozzle pieces connected with a plurality of nylon cable ties, The front end of the feeding conveyor belt 2 is provided with a feeding manipulator 3 for clamping the injection molded nozzle parts and delivering them to the feeding conveyor belt 2, and the rear end of the feeding conveyor belt 2 is provided with a nozzle part and a plurality of nylon cable ties. The cutting mechanism 4 that cuts off the junction between, the rear end of described cutting mechanism 4 is provided with the encapsulation mechanism 5 that is used to encapsulate a plurality of nylon cable ties, and transfer manipulator 6 is arranged between described cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com