Waste strip-packed cigarette processor

A processing machine and carton pack technology, which is applied in the fields of tobacco, packaging, and cigarette manufacturing, can solve the problems that carton packs of cigarettes cannot be processed, and achieve the effects of simple and reasonable structure, reduced labor intensity, and semi-automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

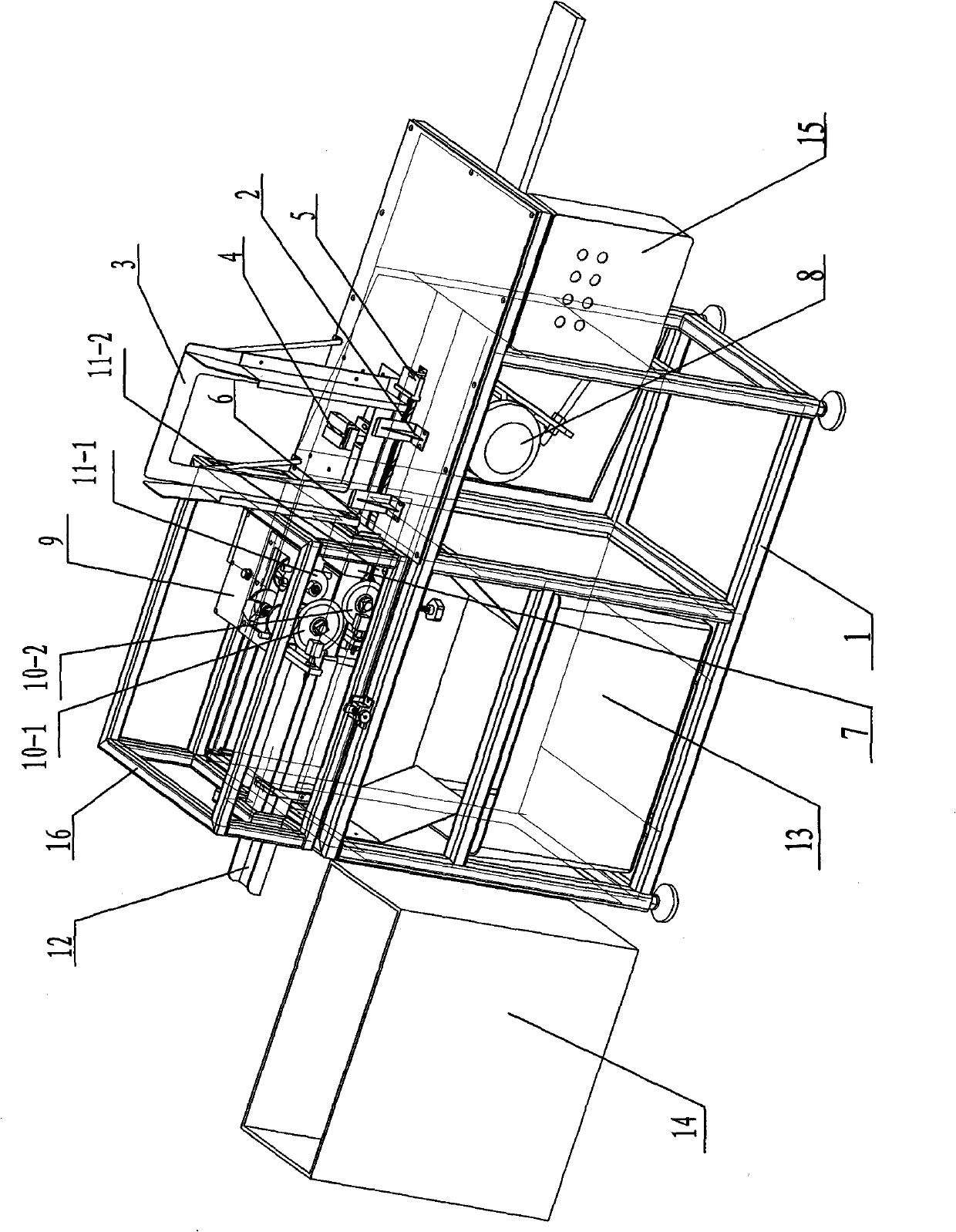

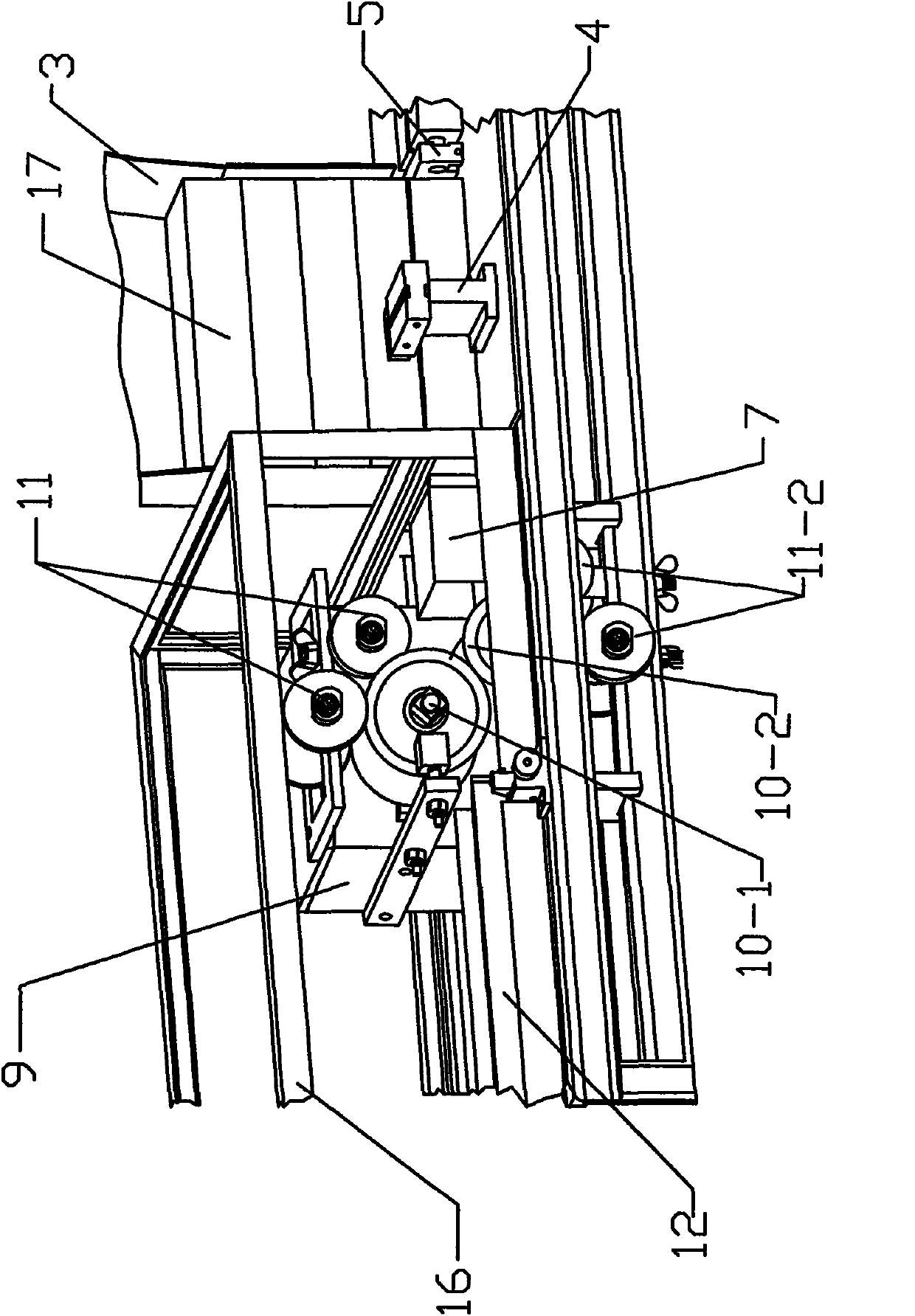

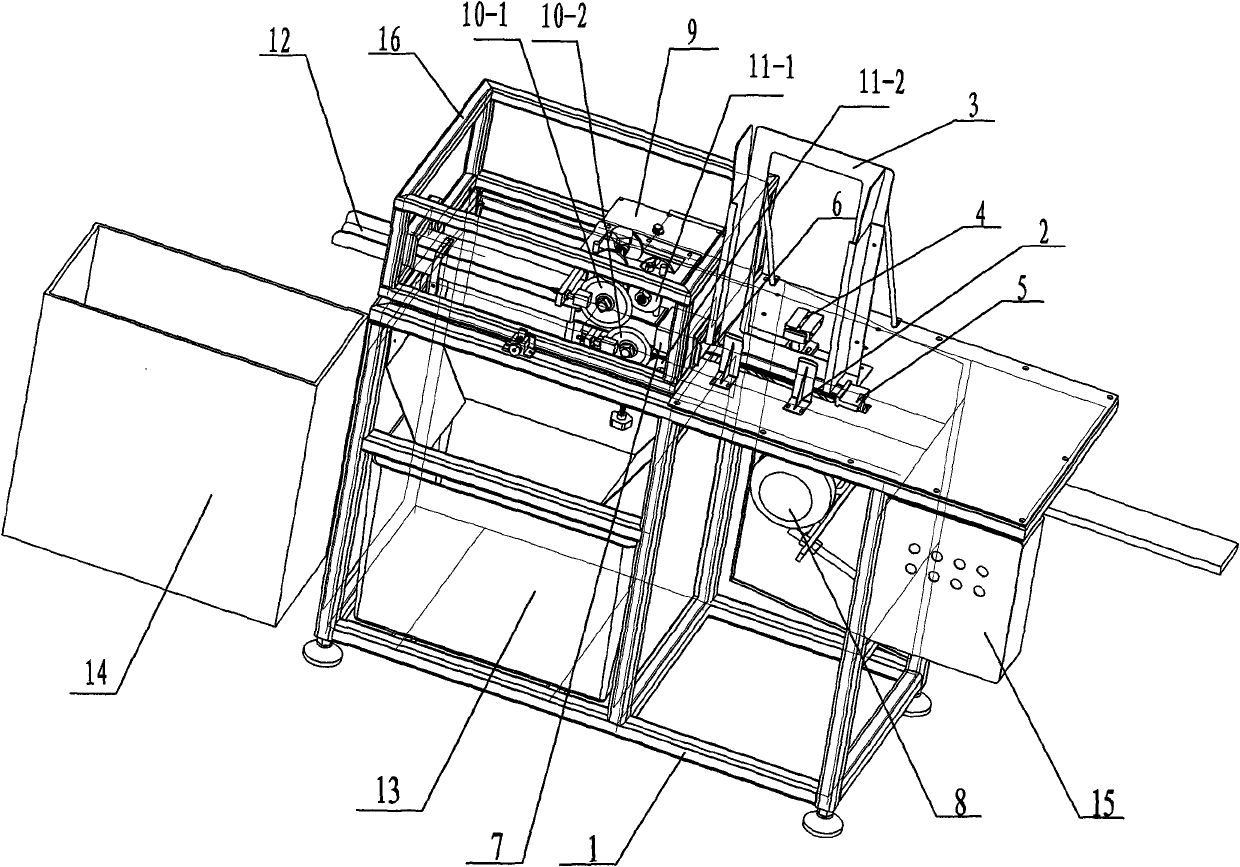

[0016] The present invention will be further described below in conjunction with accompanying drawing. figure 1 Among them, the waste pack cigarette processing machine includes a frame 1 , a motor 8 , a transmission gearbox 9 and an electrical control box 15 , and the input shaft of the transmission gearbox 9 is rotatably connected to the rotating shaft of the motor 8 . Such as figure 2 Shown, the transmission gear box 9 of the present invention is arranged on the middle part of the end face of the frame 1, and the output shaft of the transmission gear box 9 is respectively provided with upper and lower cutters 10-1, 10-2, and upper and lower grinding wheels 11-1, 11 -2, the upper and lower cutters 10-1, 10-2 and the upper and lower sharpening wheels 11-1, 11-2 are composed of two coaxially connected pieces, both on the coaxial upper and lower cutters 10-1, 10-2 is provided with cutting blades at both ends, and a sharpening wheel is provided at both ends of the coaxial upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com