Reinforced crossed shaft universal coupling

A cross-shaft universal and coupling technology, applied in the direction of couplings, elastic couplings, engine components, etc., can solve the problems of poor strength, complicated and difficult maintenance and replacement process, and achieve the effect of convenient phase adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 The base 1 is provided with a shaft sleeve 3 connecting the driving shaft or the driven shaft.

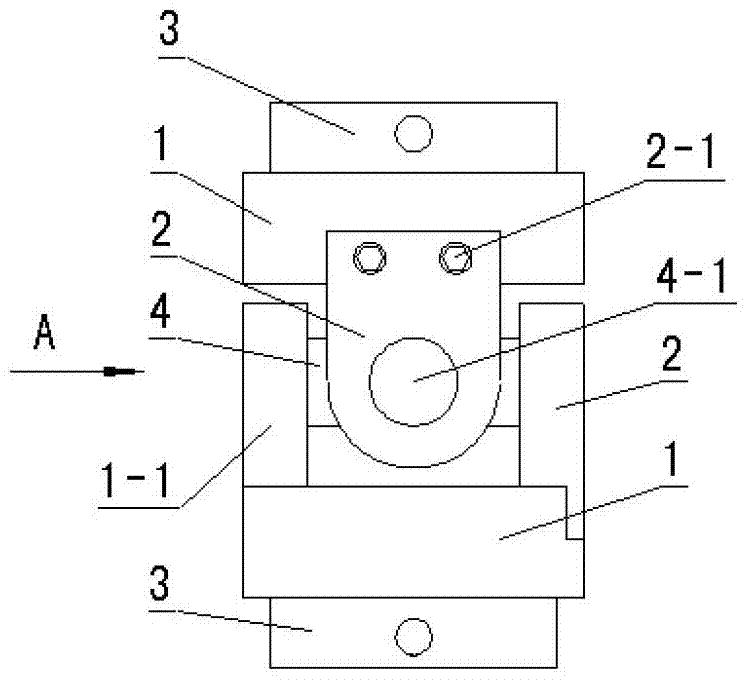

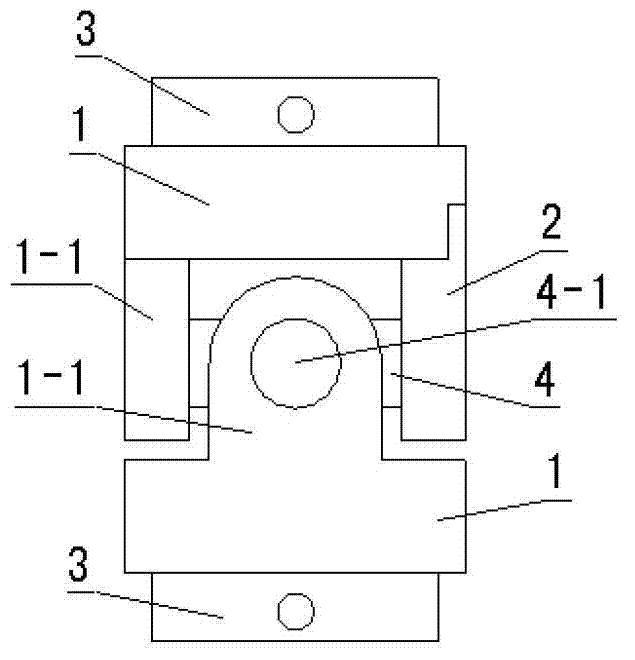

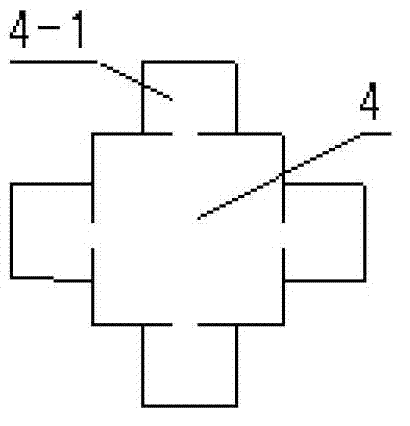

[0023] like figure 1 , 2 , Shown in 3, its symmetrical end shaft 4-1 of the integral intermediate connector 4 that is provided with the vertical intersecting axis is engaged with the shaft holes of the shaft bracket 1-1 of each fork joint and the shaft bracket plate 2 respectively.

[0024] like Figure 4 Shown in Example 2, in figure 1 , 2 3. On the basis of Embodiment 1, the shaft holes 1-1 of each fork joint and the shaft holes of the shaft bracket plate 2 are respectively provided with bearings (not shown) supporting the shafts 4-1 at the ends of the overall intermediate connector 4, Each bearing is provided with a bearing cover 5 with an oil filling hole 5-1 and a circlip 6 for fixing the bearing and its bearing cover.

[0025] like Figure 5 Shown in Example 3, in figure 1 , 2 3. On the basis of Embodiment 1, the bushing 3 of the fork joint base 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com