Strip pack device

a technology of strip pack and packing part, which is applied in the direction of packaging, etc., can solve the problems of affecting the operation of the device, the relation to the conveying part becomes a problem, and the weight of the product cannot be tested before the device, so as to achieve the effect of moving even more smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

Overall Configuration Of Strip Pack Device

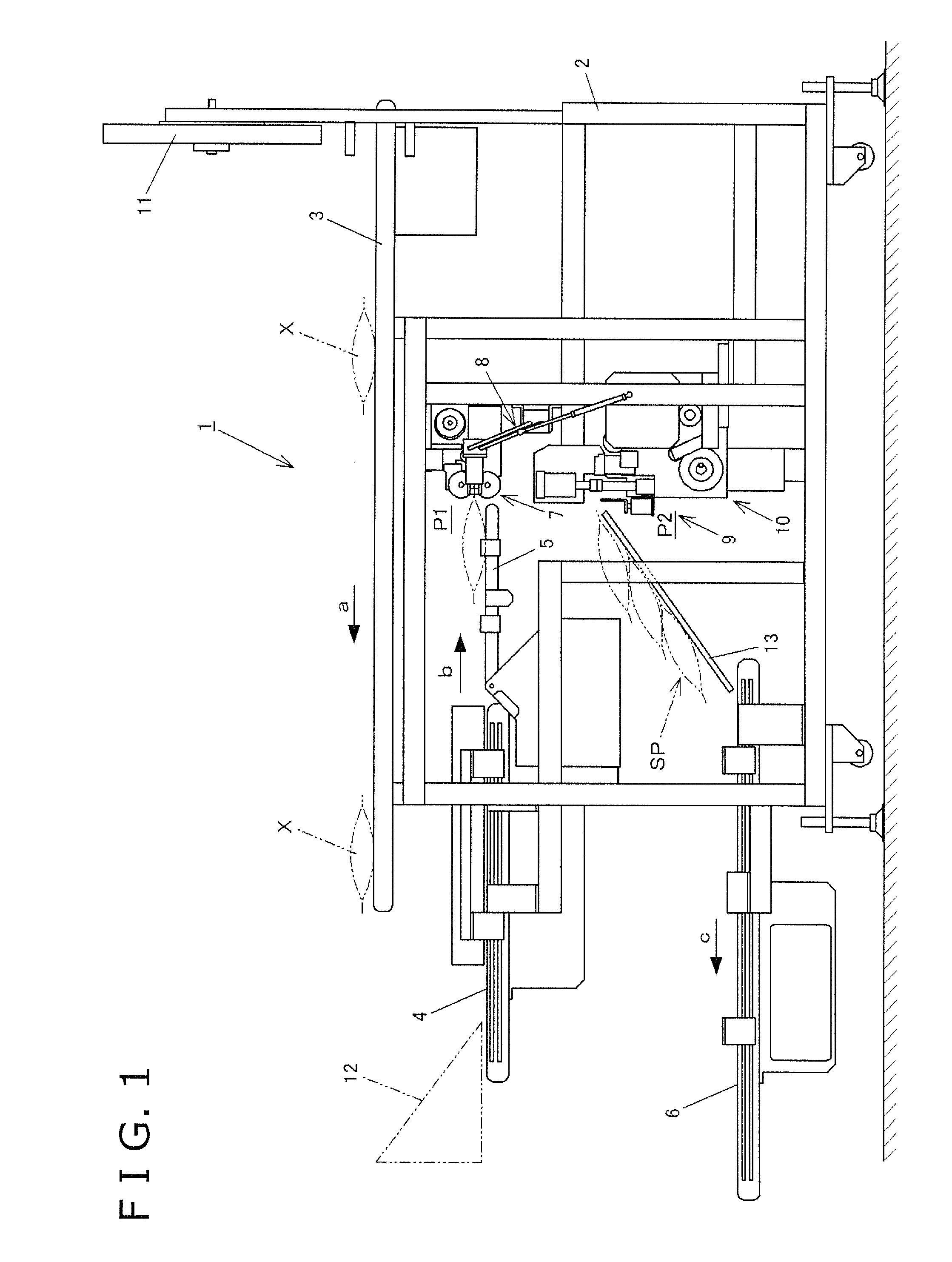

[0034]A strip pack device 1 according to the first embodiment of the present invention comprises a main unit 2, a supply conveyor 3, an induction conveyor 4, a drop conveyor 5, a discharge conveyor 6 (an example of the conveying part), a brush unit 7 (an example of the drawing-in part), grasping units 8 (an example of the moving part), an attachment unit 9 (an example of the attachment part), a tape feed unit 10, a falloff prevention member 12, a cradle 13, and other components, as shown in FIG. 1.

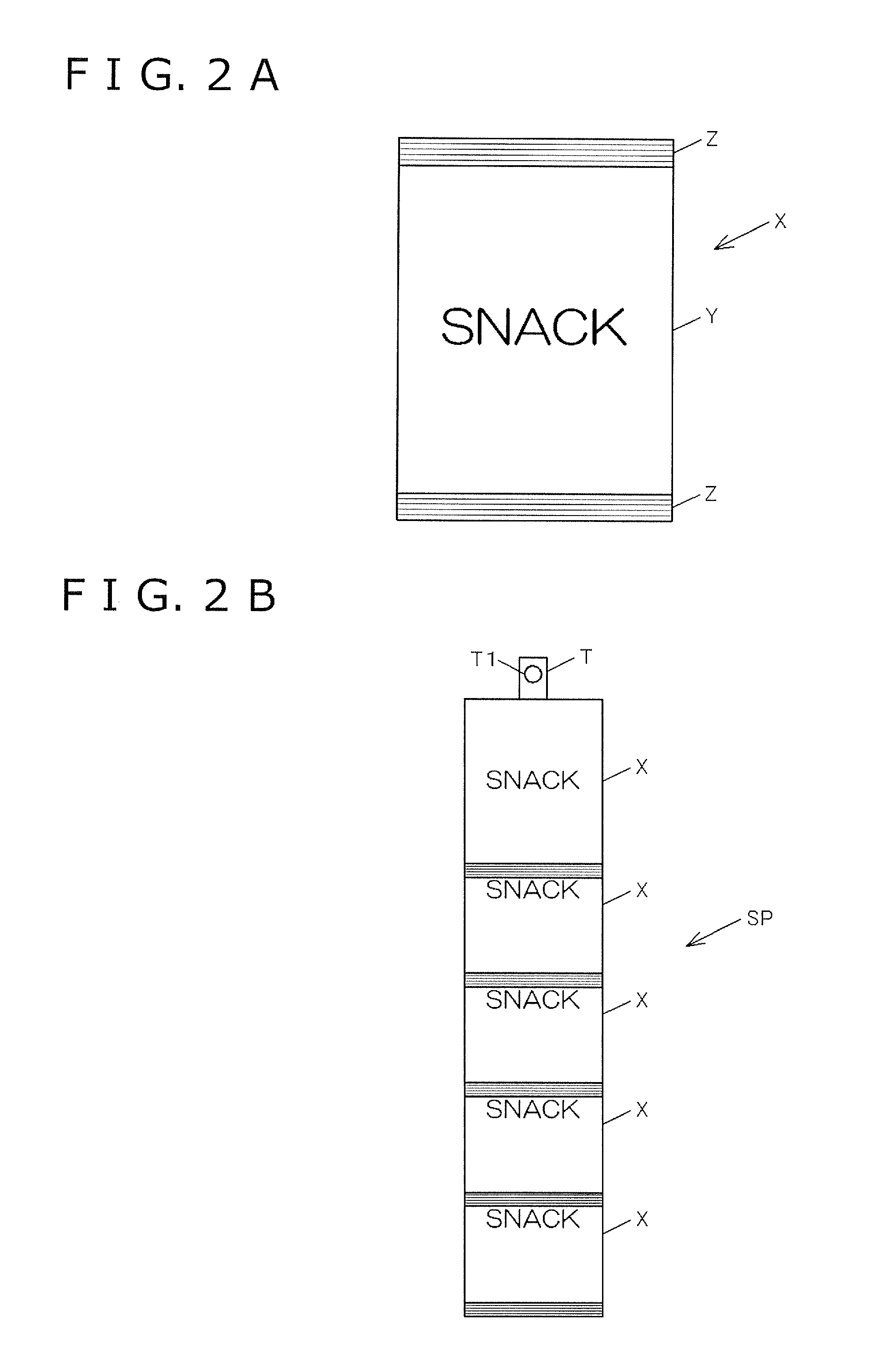

[0035]Bags X filled with, e.g., snack foods or the like are supplied as handled articles to the supply conveyor 3 from an upstream device.

[0036]The induction conveyor 4 guides bags X supplied in the direction of the arrow a by the supply conveyor 3 into the main device 1, as shown by the arrow b.

[0037]The drop conveyor 5 constitutes the terminal end of the induction conveyor 4.

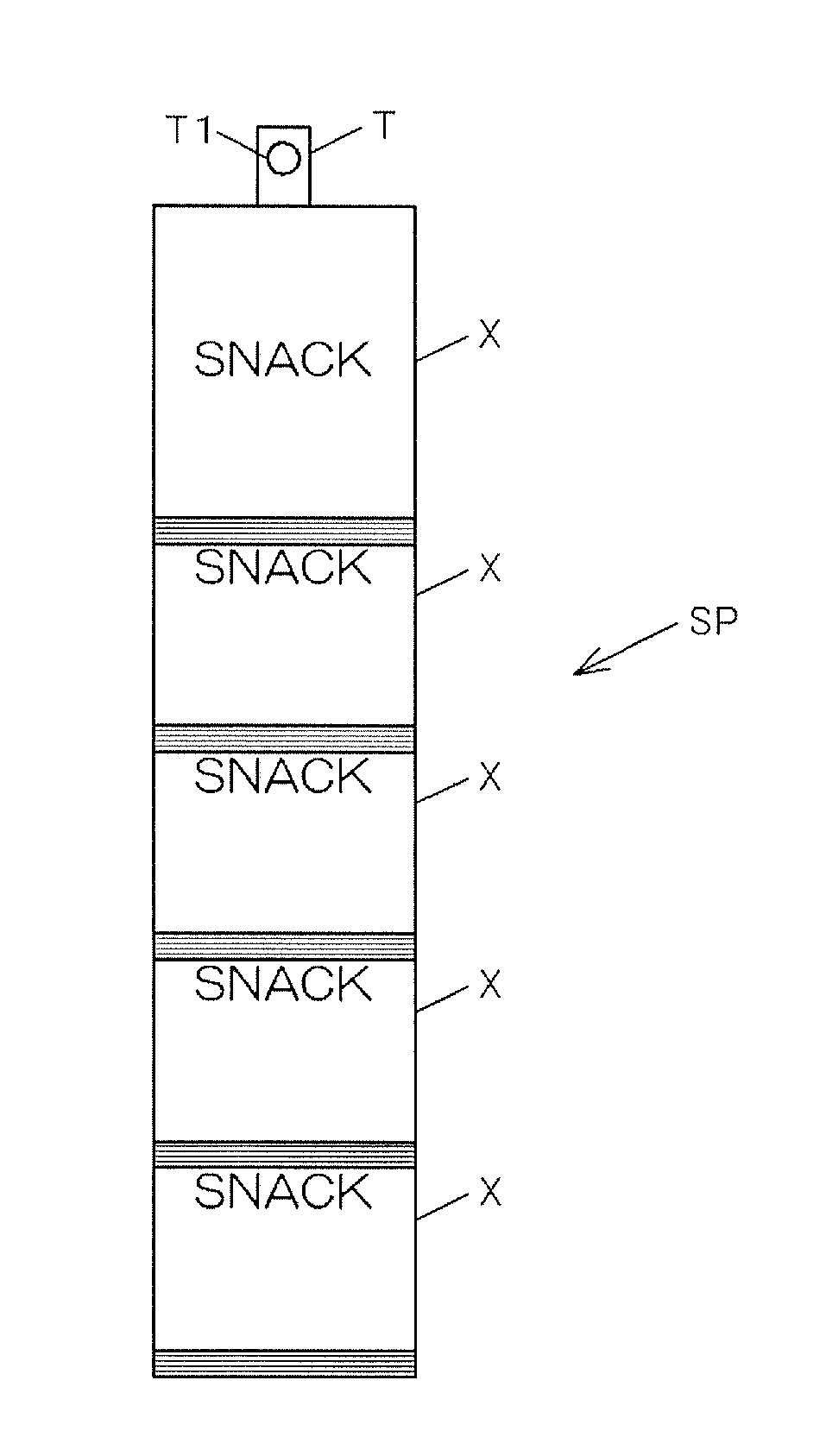

[0038]The discharge conveyor 6 discharges a strip pack SP made of a plur...

second embodiment

[0072]Next, a strip pack device according to the second embodiment of the present invention will be described. Structural elements common to the first embodiment previously described are denoted by the same numerical symbols.

[0073]This strip pack device has the same configuration as the first embodiment except for the grasping units. With these grasping units 108, it is possible to adjust the forward-backward positions of the grip fingers 81, 81 for grasping the sealed parts Z of bags X drawn in by the upper and lower brushes 76, 76 of the brush unit 7, and pneumatic cylinders 188 (an example of the opposite-direction-moving part) are provided for this purpose, as shown in FIG. 8. The grip fingers 81, 81 are attached via hands 82 to the distal ends of rods that reciprocate in the direction of the arrow g, g′ of the pneumatic cylinders 188. The pneumatic cylinders 188 are linked via attachment members 183 to the ends on one side of link members 84, 84, 85, 85 (only one pair on one si...

third embodiment

[0078]Next, a strip pack device according to the third embodiment will be described. Structural elements common to the first embodiment are denoted by the same numerical symbols in this case as well.

[0079]The configuration of this strip pack device is also the same as the first embodiment except for the grasping units. Specifically, the grasping units 208 in this case are disposed farther forward in the conveying direction b than the terminal end of the drop conveyor 5 that pivots around the starting end in the direction of the arrow e, as shown in FIGS. 10 through 12. The grasping units 208 grasp the sealed parts Z in the front of the bags X in the conveying direction from above and below in the front of the conveying direction b, by a pair of upper and lower grip fingers 81, 81, similar to the first embodiment. The grasping units 208 move the grasped bags X from the drawn-in position P1 in the brush unit 7 to the attaching position P2 in the attachment unit 9.

[0080]The grip finger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com