Roller enhancing type strip packing machine

An enhanced, packaging machine technology, applied in packaging, transport packaging, multiple packaging, etc., can solve problems such as insufficient sealing of packaging bags, packaging bag pollution, wire drawing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

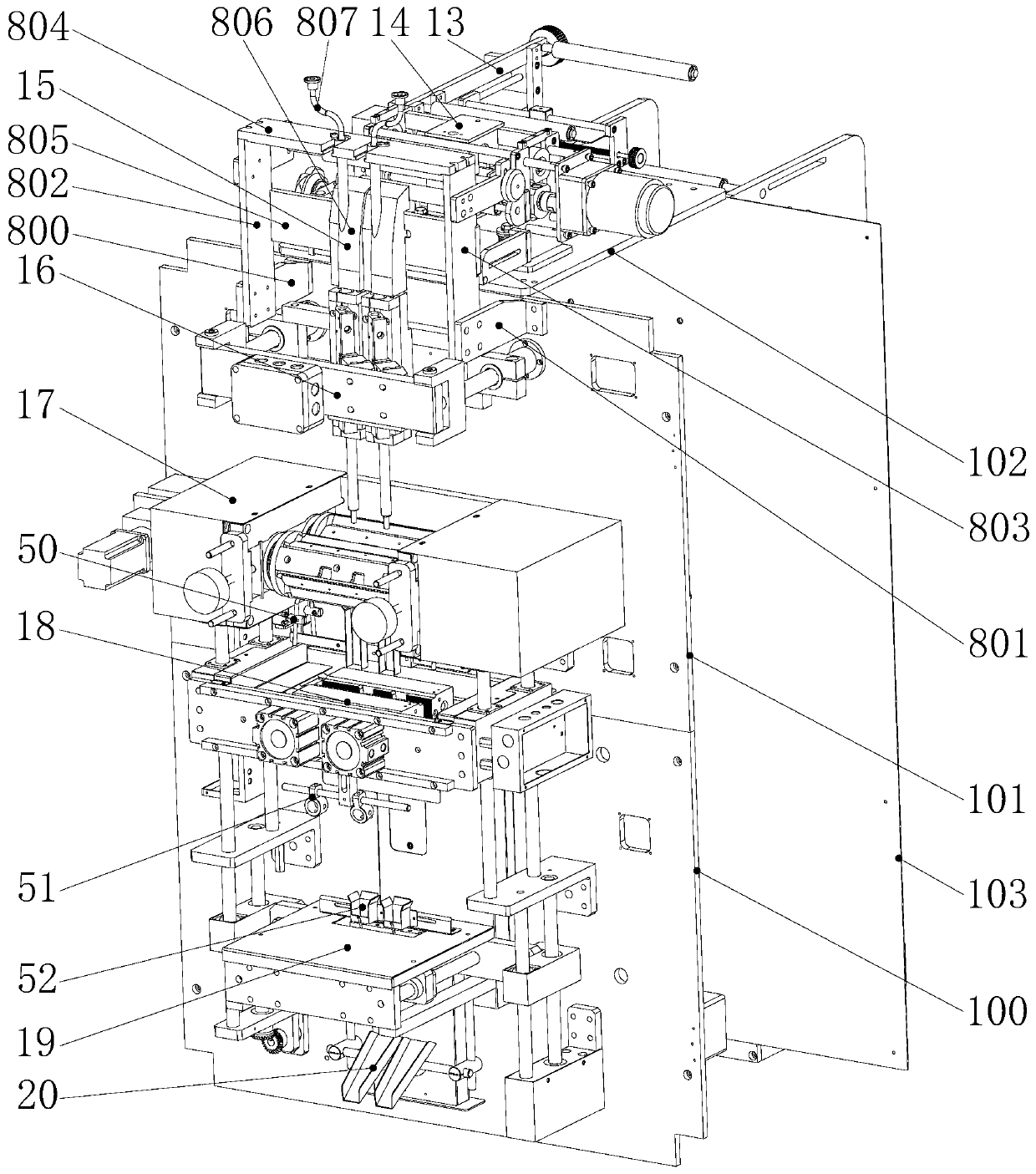

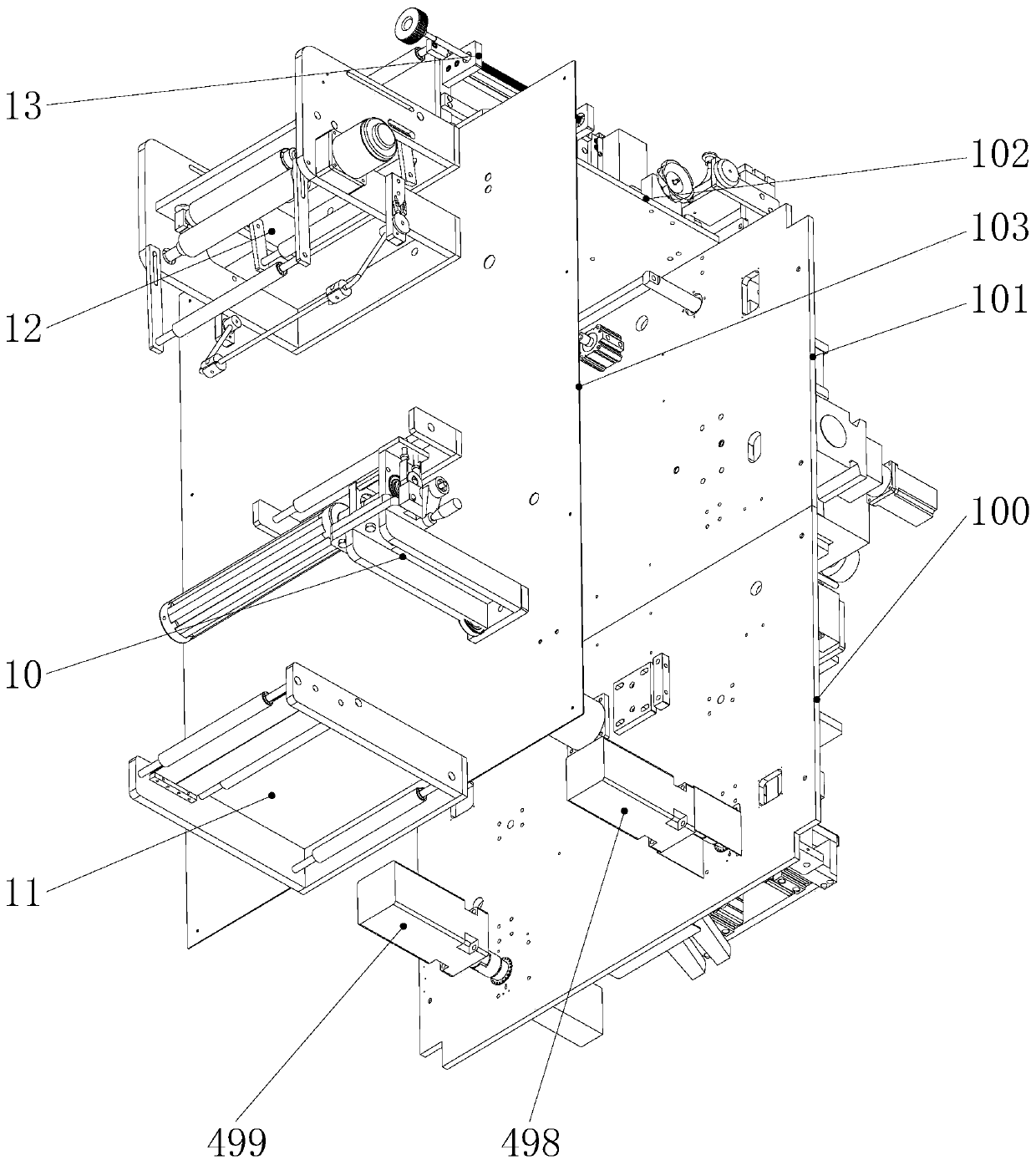

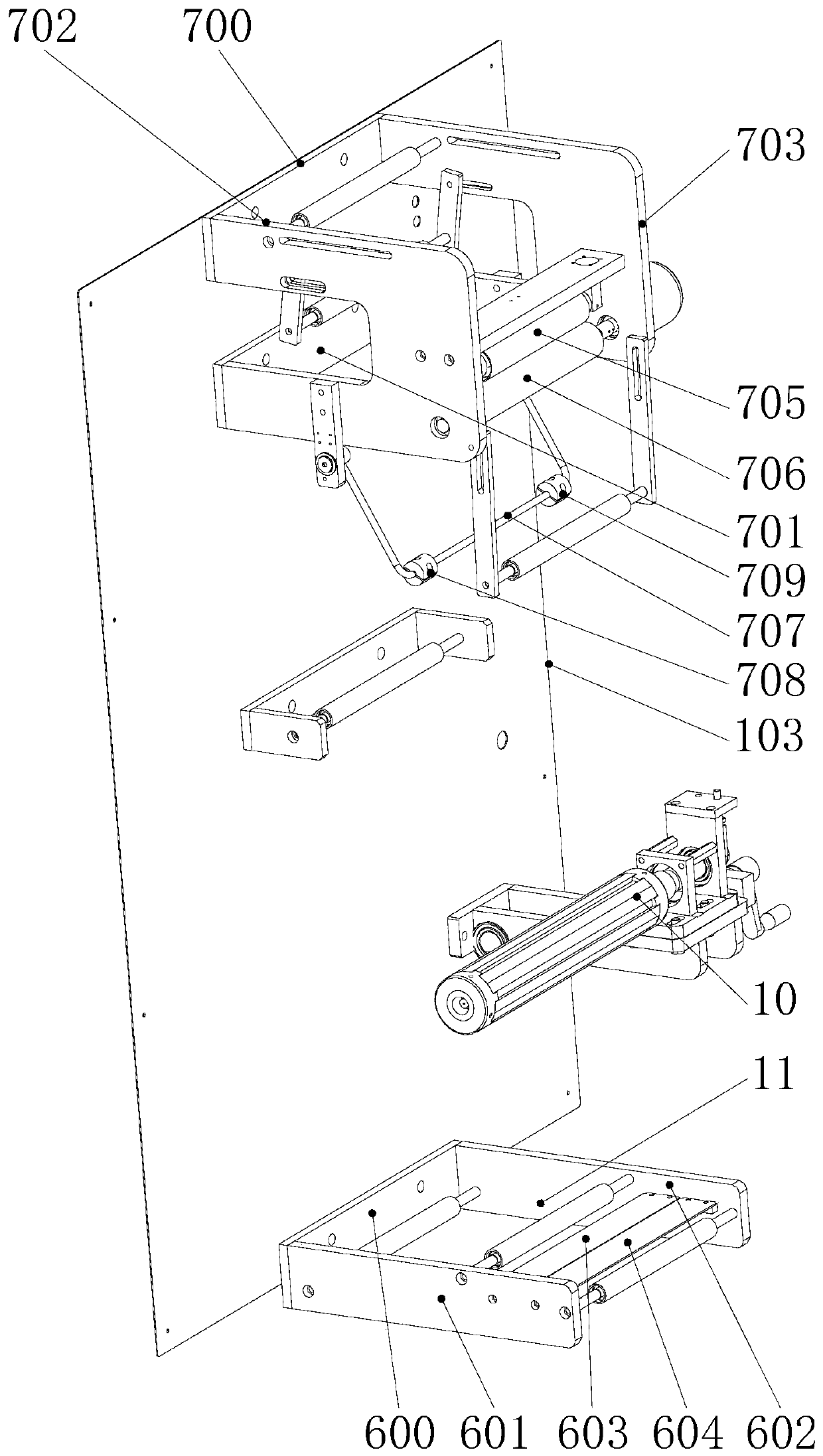

[0035] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

[0036] As shown in the accompanying drawings, the present invention provides a roller-reinforced strip packaging machine, which includes a film roll device 10, a film splicing device 11, a film feeding device 12, a color code adjustment device 13, a center cut The device 14, the former device 15, the longitudinal sealing device 16, the roller device 17, the horizontal sealing device 18, the cutting device 19 and the discharge device 20, the film roll device 10, the film splicing device 11 and the film feeding device 12 are installed on the rear plate 103 The rear side is installed on the column of the machine at the same time. A front base plate arranged parallel to it is arranged in front of the rear plate 103. A top plate 102 is arranged on the top of the rear plate 103 and the front base plate. Due to the requirements of technology and cost, the front base pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com