Strip-pack manufacturing apparatus

a manufacturing apparatus and strip-pack technology, applied in the direction of packaging, etc., can solve the problems of difficult stabilization and positioning of articles, difficult to reliably affix, and reduce the product value from the perspective of appearance, so as to improve the appearance of affixing and reduce the product value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]Selected embodiments of the present invention will now be explained with reference to the drawings. It will be apparent to those skilled in the art from this disclosure that the following descriptions of the embodiments of the present invention are provided for illustration only and not for the purpose of limiting the invention as defined by the appended claims and their equivalents.

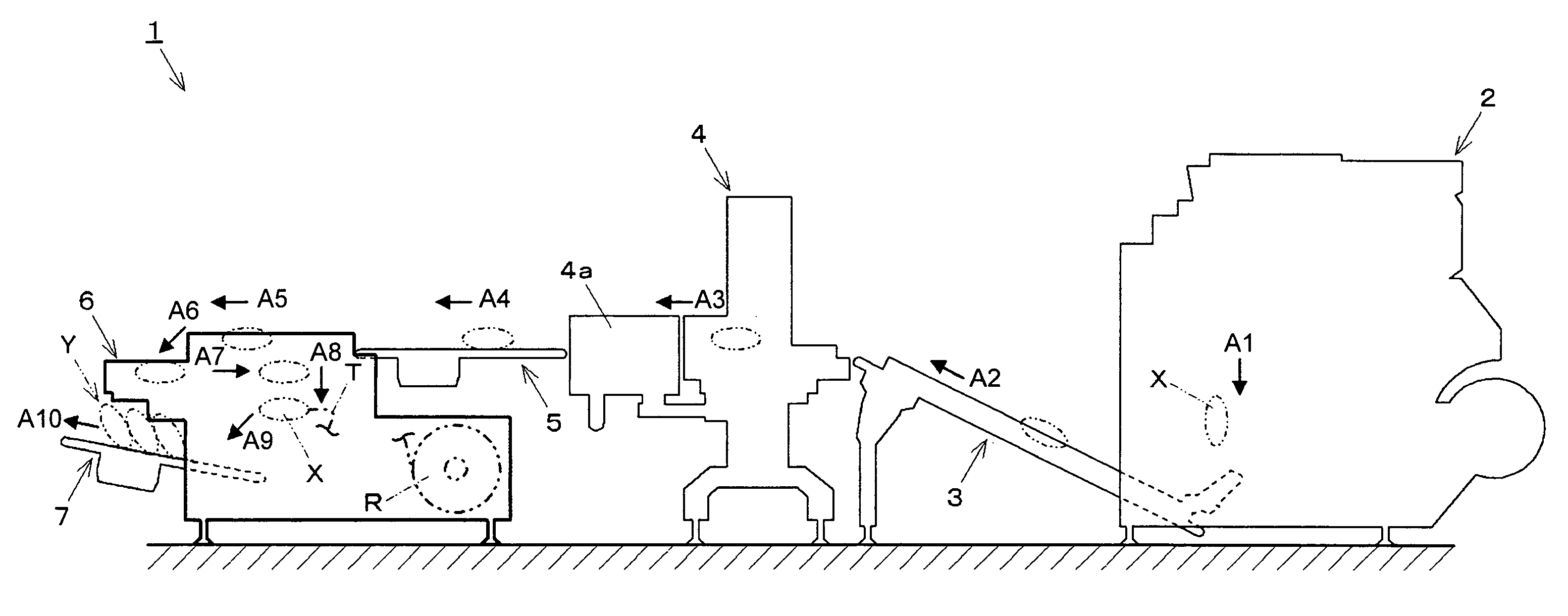

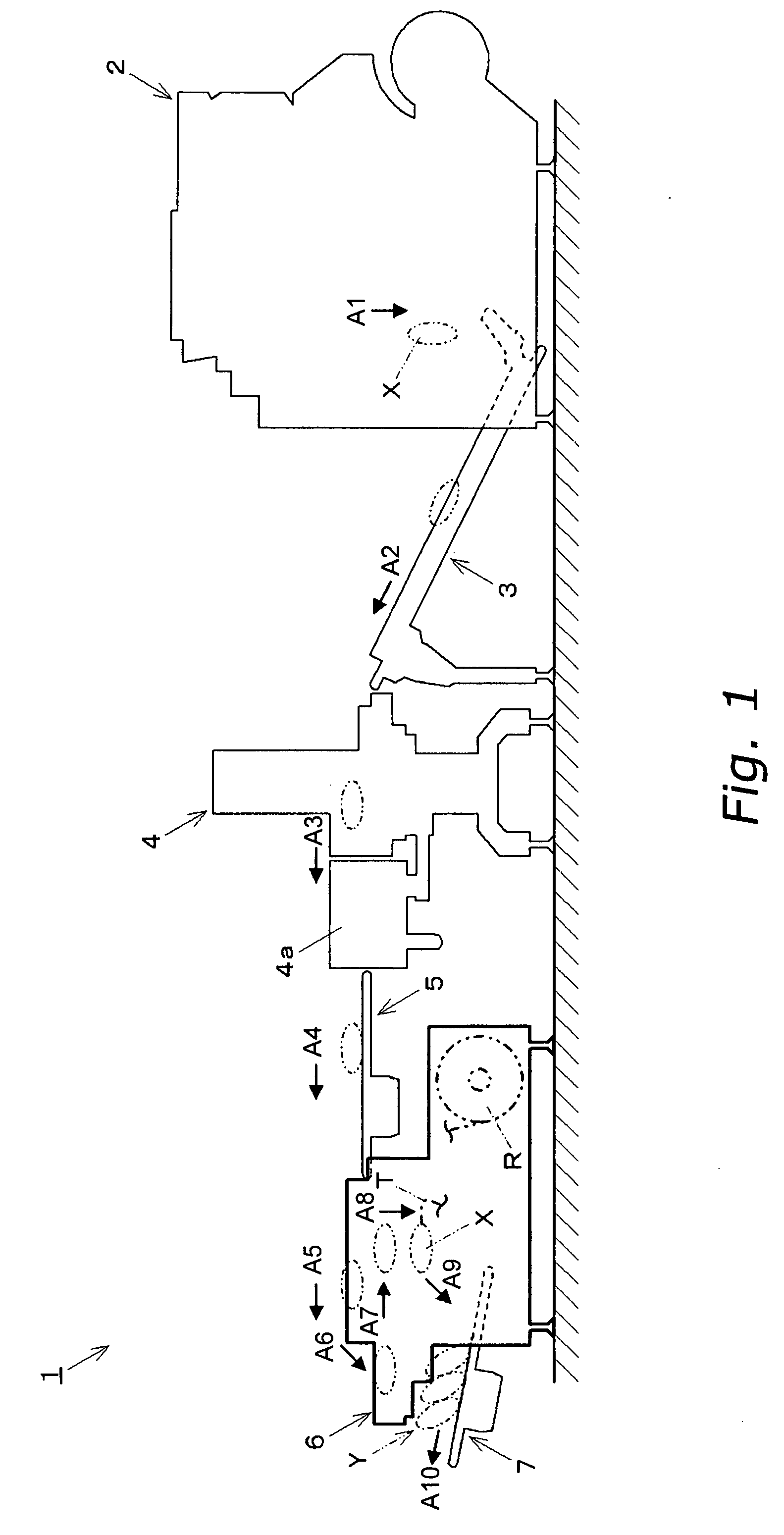

[0041]Referring initially to FIG. 1, a manufacturing system 1 including a string-pack manufacturing apparatus 6 is illustrated in accordance with a preferred embodiment of the present invention.

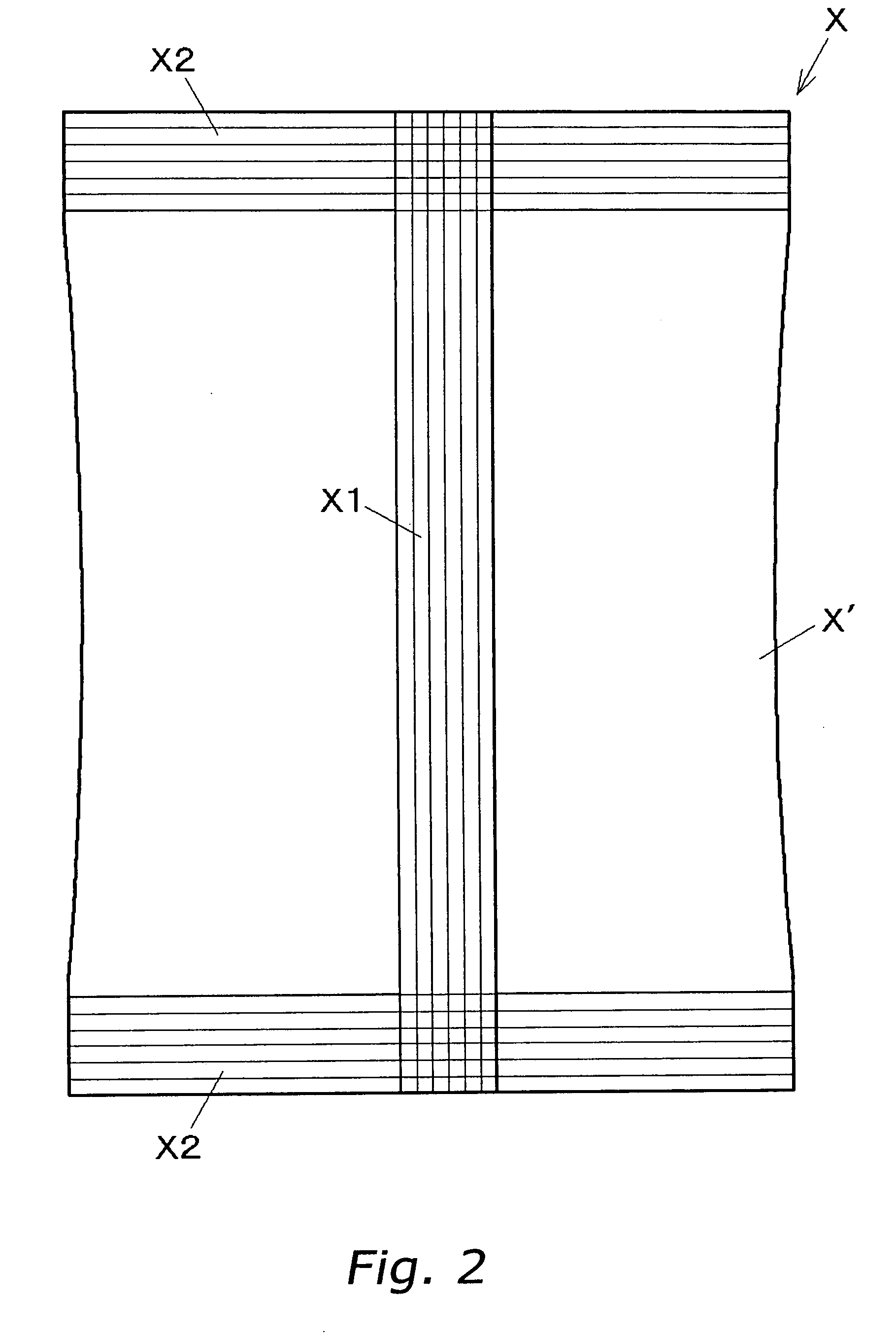

[0042]As shown in FIG. 1, the manufacturing system 1 is configured and arranged to manufacture a plurality of strip-packs Y as products by manufacturing a plurality of bagged articles X that are each filled with contents such as snack food, and then by affixing a prescribed number of the articles X to a strip-shaped tape T, which is fed from a tape roll R. The manufacturing system 1 includes, starting from a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com