Steel strip packer with steel belt stagger cutting function and steel belt packing method

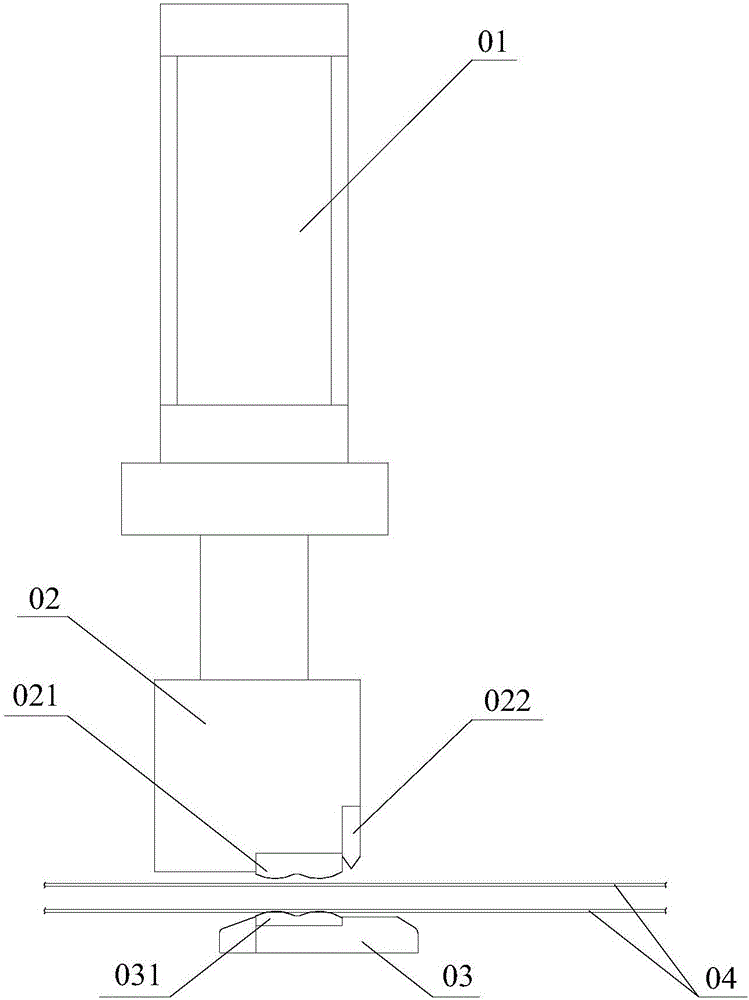

A steel strip and strip plate technology, applied in the field of steel strip balers, can solve problems such as unfavorable service life, aggravated loss of punching blade 022, unfavorable steel strip 04 tightness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] Words such as "first" and "second" mentioned herein are only used to describe two or more components or structures with the same or similar structure, and do not represent a special limitation on the order.

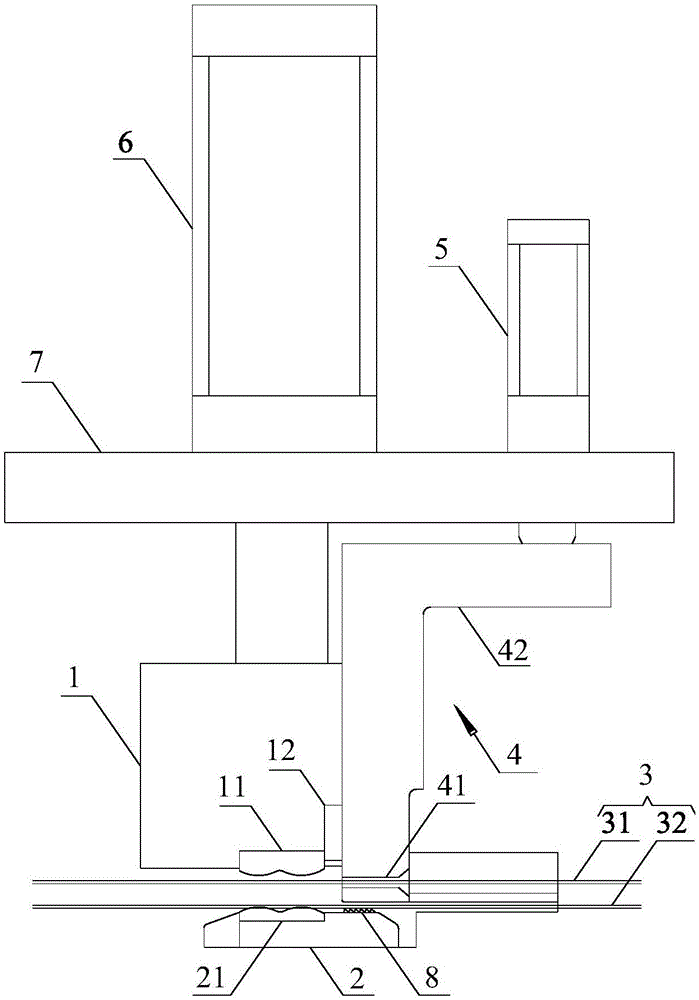

[0036] Please refer to figure 2 , figure 2 It is a structural schematic diagram of a specific embodiment of a steel strip baler capable of staggeredly shearing steel strips provided by the present invention.

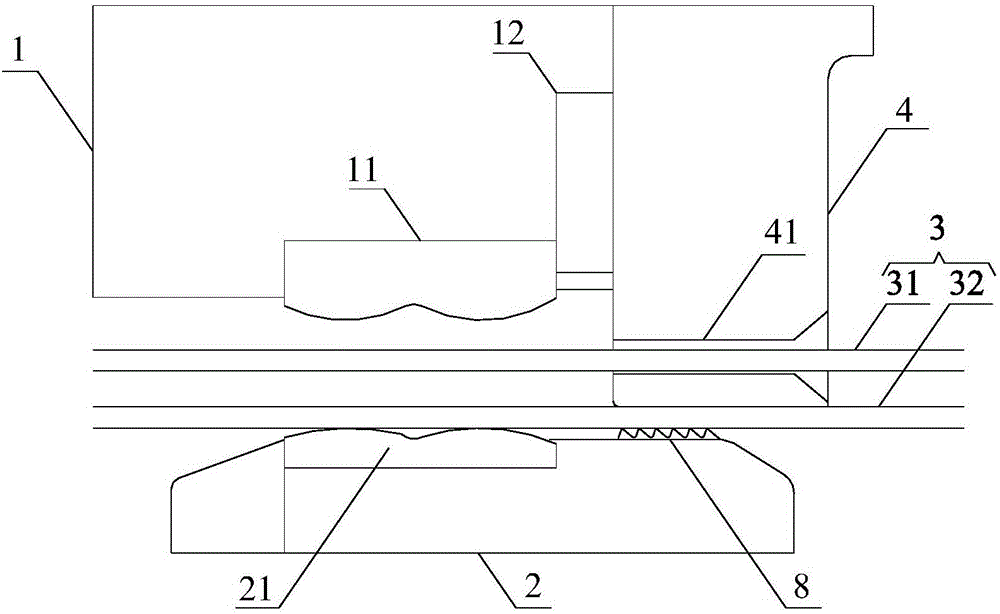

[0037] Such as figure 2 As shown, the present invention provides a steel strapping machine capable of staggered shearing of steel strips, comprising a first knife seat 1, a second knife seat 2 and a leader belt component, the first knife seat 1 can move in the axial direction, the first knife seat 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com