Horizontal plane motion mechanism for towing tank test

A planar motion mechanism and pool ship model technology, which is applied to ship parts, ship construction, ship design, etc., can solve the problems of large hydraulic drive volume, high sealing requirements, and easy pollution of pools, etc., and achieve high positioning accuracy and convenient control , the effect of flexible transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

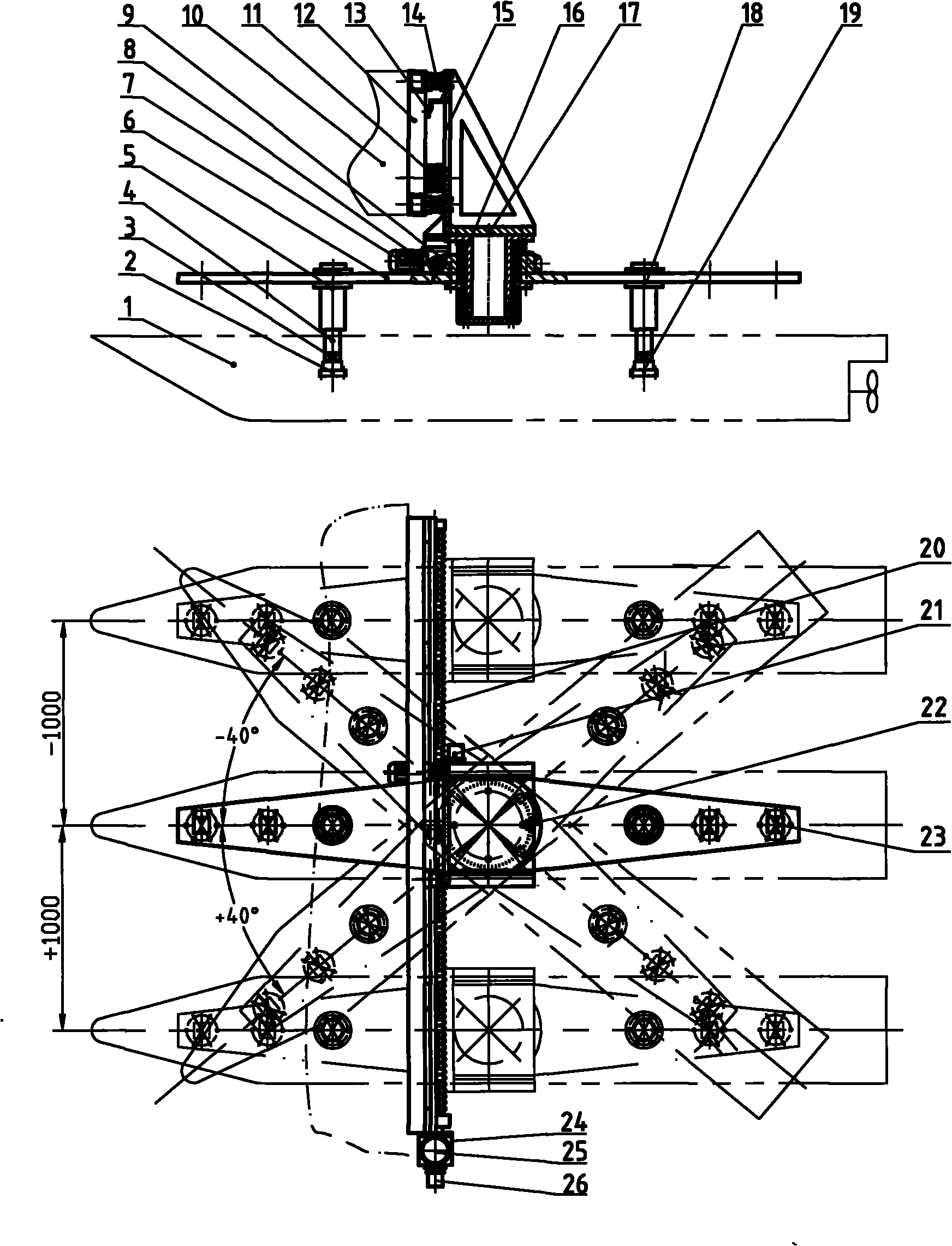

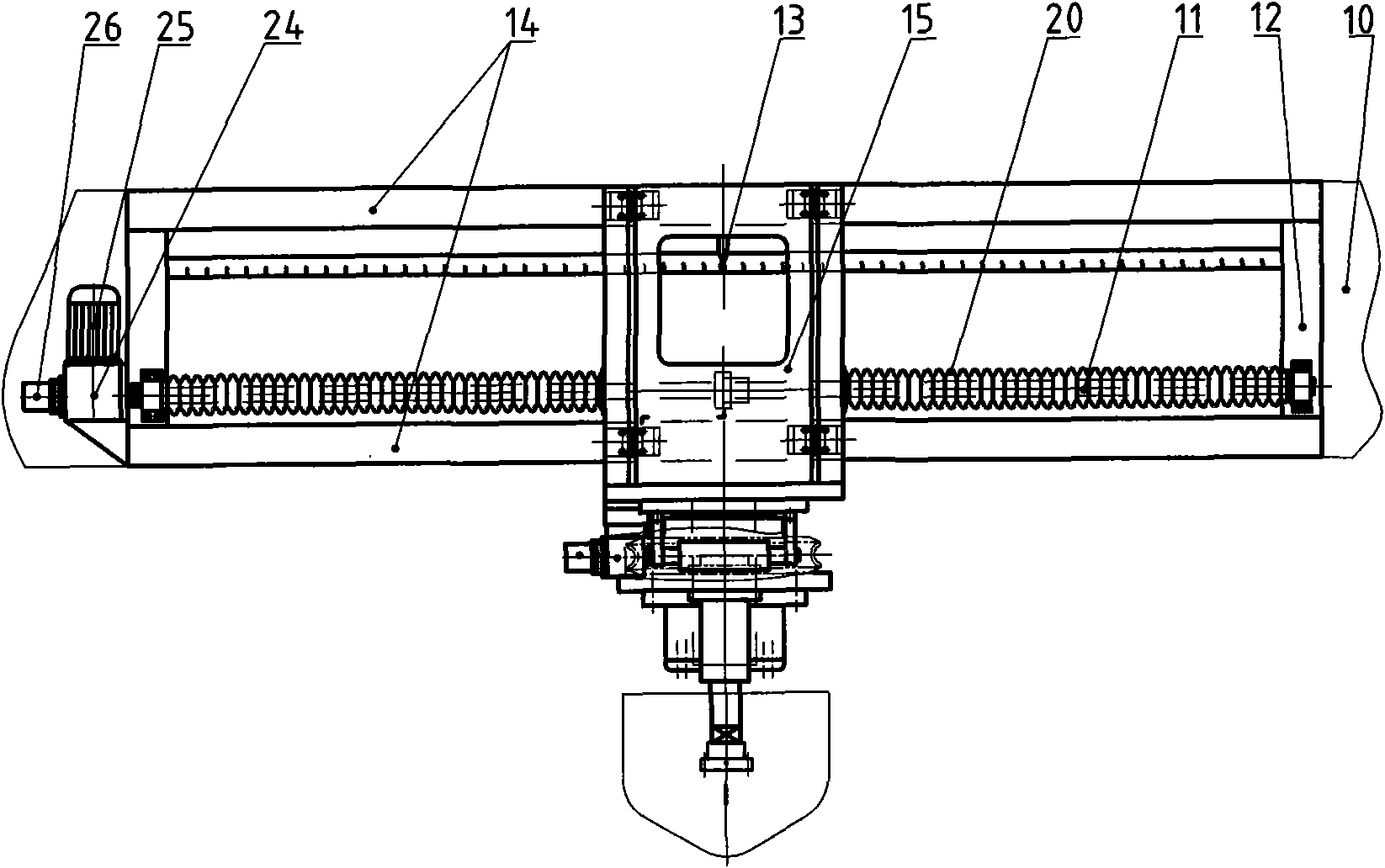

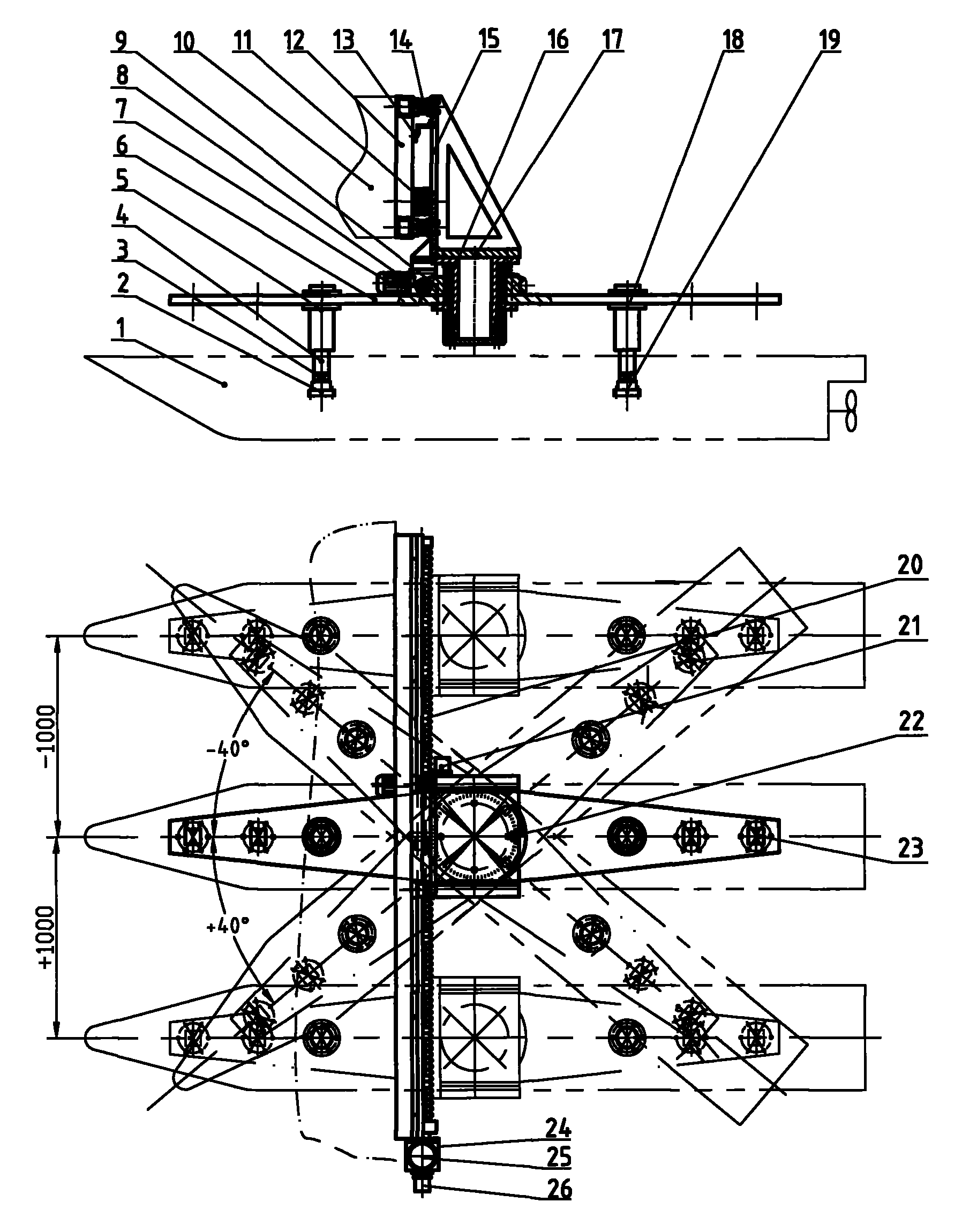

[0014] The planar motion mechanism for tank ship model test of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0015] Such as figure 1 As shown, the water plane plane motion mechanism for the tank ship model test of the present invention includes a sway mechanism frame 12 fixed to the tank ship model trailer 10, a rolling guide rail 14, a sway bracket 15, a ball screw 11, and a screw sheath 20 , sway scale 13, sway servo motor 25, gearbox 24, encoder 26 form sway moving parts. The bearing block 17 connected with the swing bracket 15, the self-lubricating bearing 16, the worm gear 9, the yaw servo motor 7, the gearbox 8, the encoder 21, the yaw scale 22, and the beam 6 form the yaw moving parts. The connecting rod installation holes 23 with different distances are arranged on the beam 6 . There are linear bearings in the front and rear connecting rods 5 and 18, the front and rear connecting rods 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com