Road guardrail cleaning machine

A cleaning machine and cleaning mechanism technology, applied in the field of cleaning machines, can solve the problems of inability to meet cleaning requirements, hidden dangers to personal safety, affecting driving safety, etc., and achieve the effects of eliminating complicated labor, high safety, and high degree of chemistry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

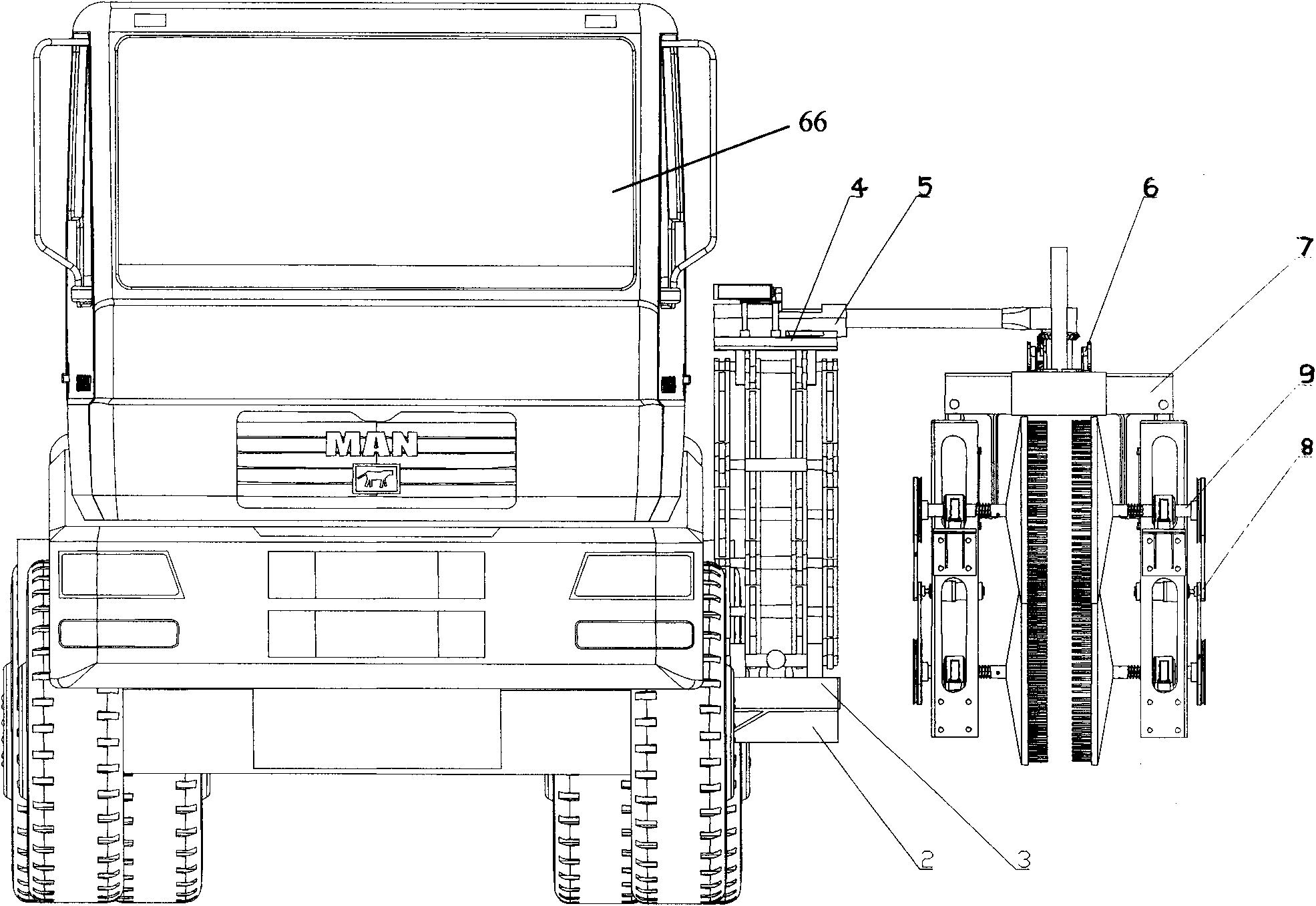

[0028] Below in conjunction with accompanying drawing, the specific structural features of the guardrail cleaning machine provided by the invention are described in detail as follows:

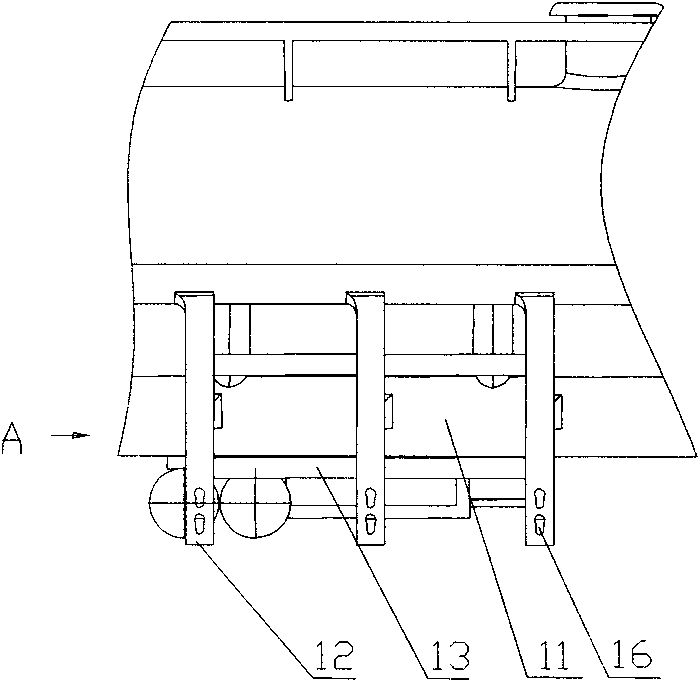

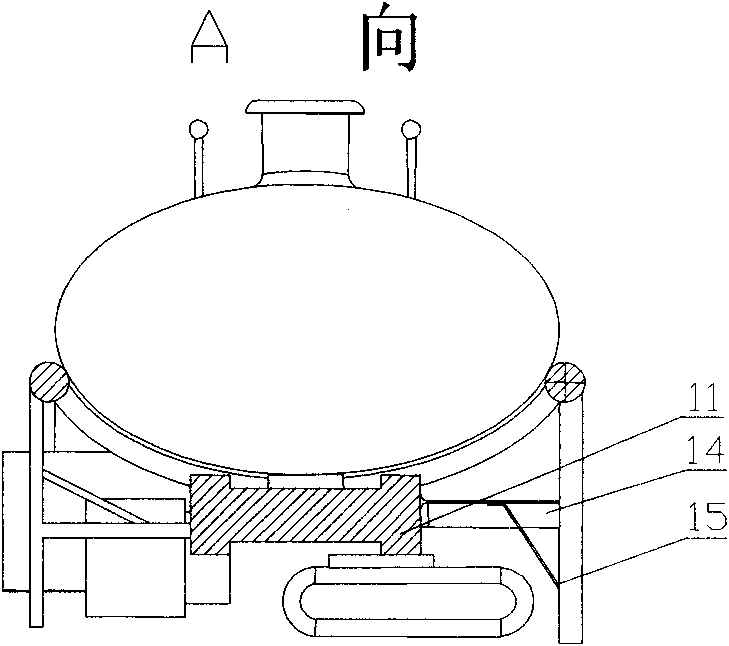

[0029] Such as figure 1 Shown is the front view of the road guardrail cleaning machine. The cleaning machine at least includes a mounting seat fixed on the side of the locomotive 66, a steel frame 1, a hanger 2, a lifting mechanism 3, a rotating mechanism 4, a telescopic mechanism 5, a lifting platform 28, and a turning mechanism. Mechanism 6, gantry clamping mechanism 7, cleaning brush mechanism 8, adapting mechanism 9 and water spray device; Link to each other with the lifting mechanism 3 and the mounting seat, the lifting device 3 base is fixed on the installation platform on the frame of the hanger 2, the lifting mechanism 3 and the rotating mechanism 4 are installed on the lifting platform, such as Figure 6 As shown, the telescopic mechanism 5 is connected with the turning mechanism 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com