Blast tube of tunnel

A technology of blasting tubes and tunnels, applied in the field of blasting tubes, which can solve the problems of high labor intensity of blasting construction personnel, prolonging the operation time of blasting procedures, and difficulty in popularization and application, and achieves the effects of convenient and quick loading, saving explosives, and small damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

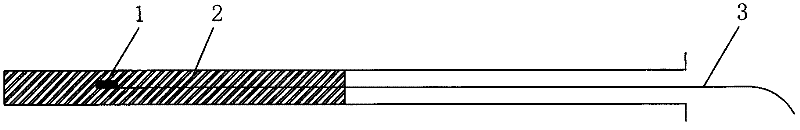

[0014] in figure 1 In the prior art, blast holes are drilled at the construction site, explosives are continuously loaded in the blast holes, the detonating tube is loaded into the explosives, and the detonating index is indexed out of the blast hole. The upper hole of the blast hole is not backfilled and blocked, but directly The detonating tube exploded the explosive in the blasthole.

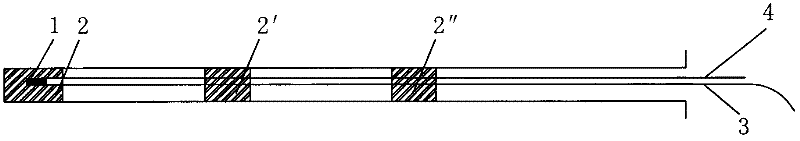

[0015] in figure 2 In the prior art, explosives are spaced in the blast hole, the detonating tube is installed in the explosive and the detonating index is out of the blast hole. The upper hole of the blast hole is not backfilled and blocked, and the detonating tube is directly ignited to make the blast hole. The explosive inside exploded.

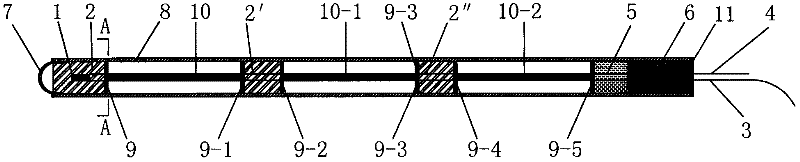

[0016] In the present invention image 3 , Figure 5 In the embodiment, first install and fix the left end cap 7 with the tapered head on the left end of the plastic pipe 8. The first cylindrical explosive 2 is installed in the pipe hole at the left end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com