Unitary breechblock assembly

a breechblock and assembly technology, applied in the field of single-shot break action firearms, can solve the problems of affecting the performance of cartridges, high cost, and breechblock portion of the receiver can become worn by the pivoting motion of the barrel, and achieves the effects of low cost, low cost, and minimal manufacturing cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

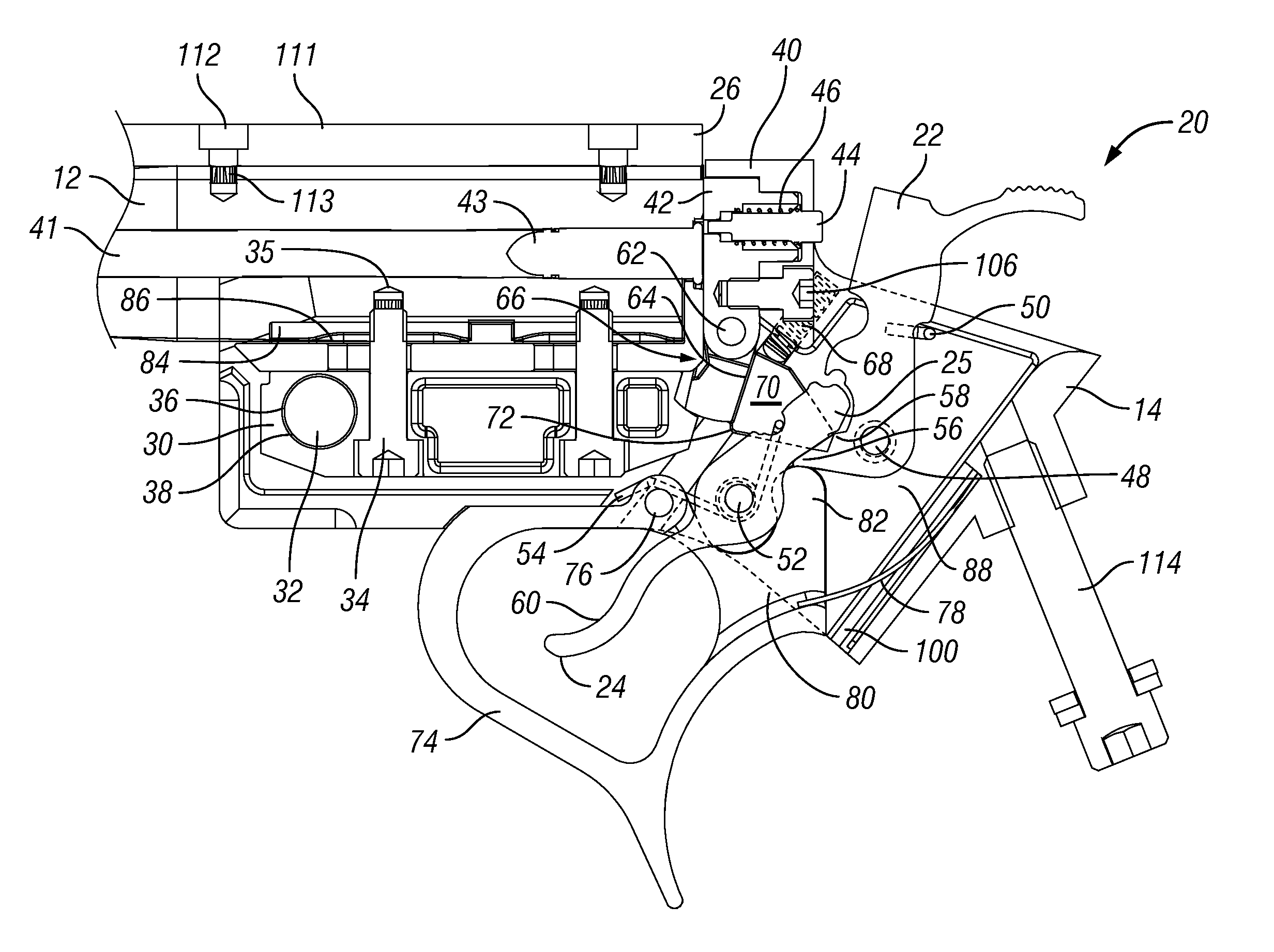

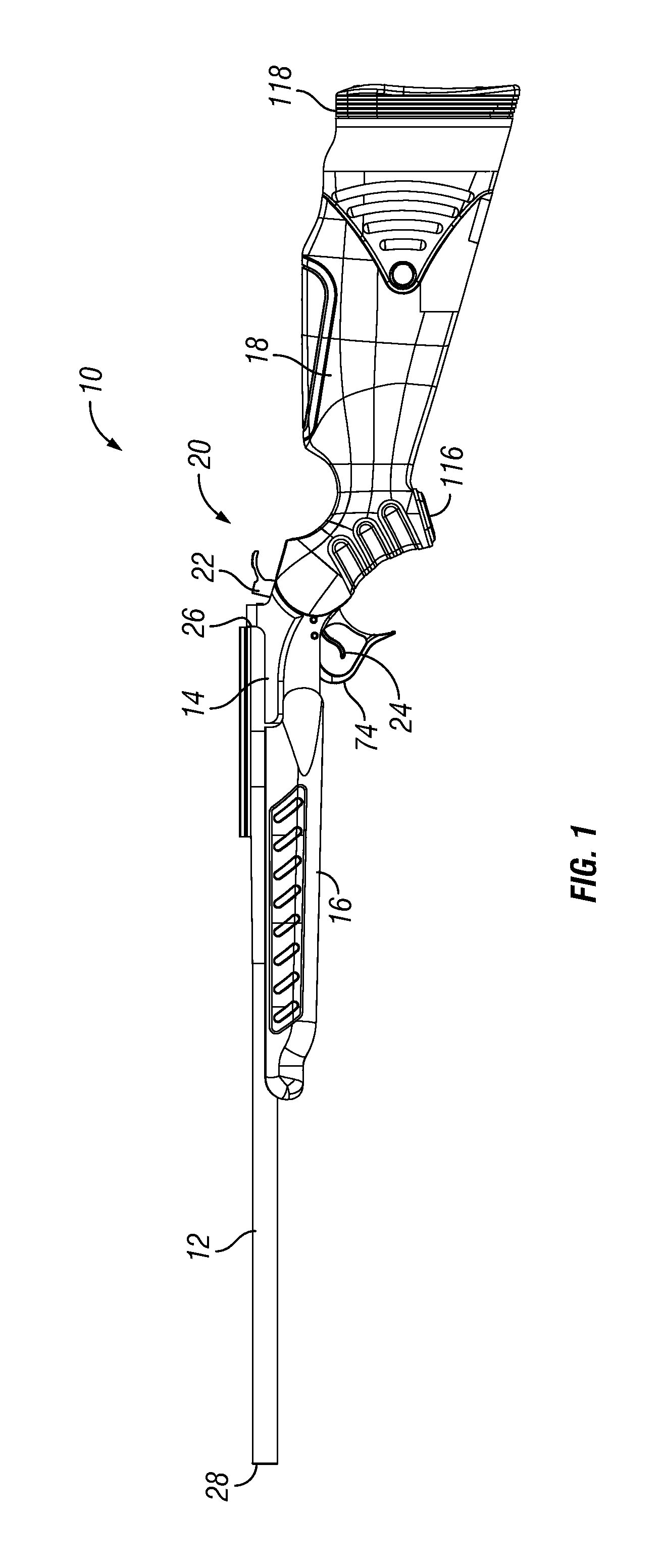

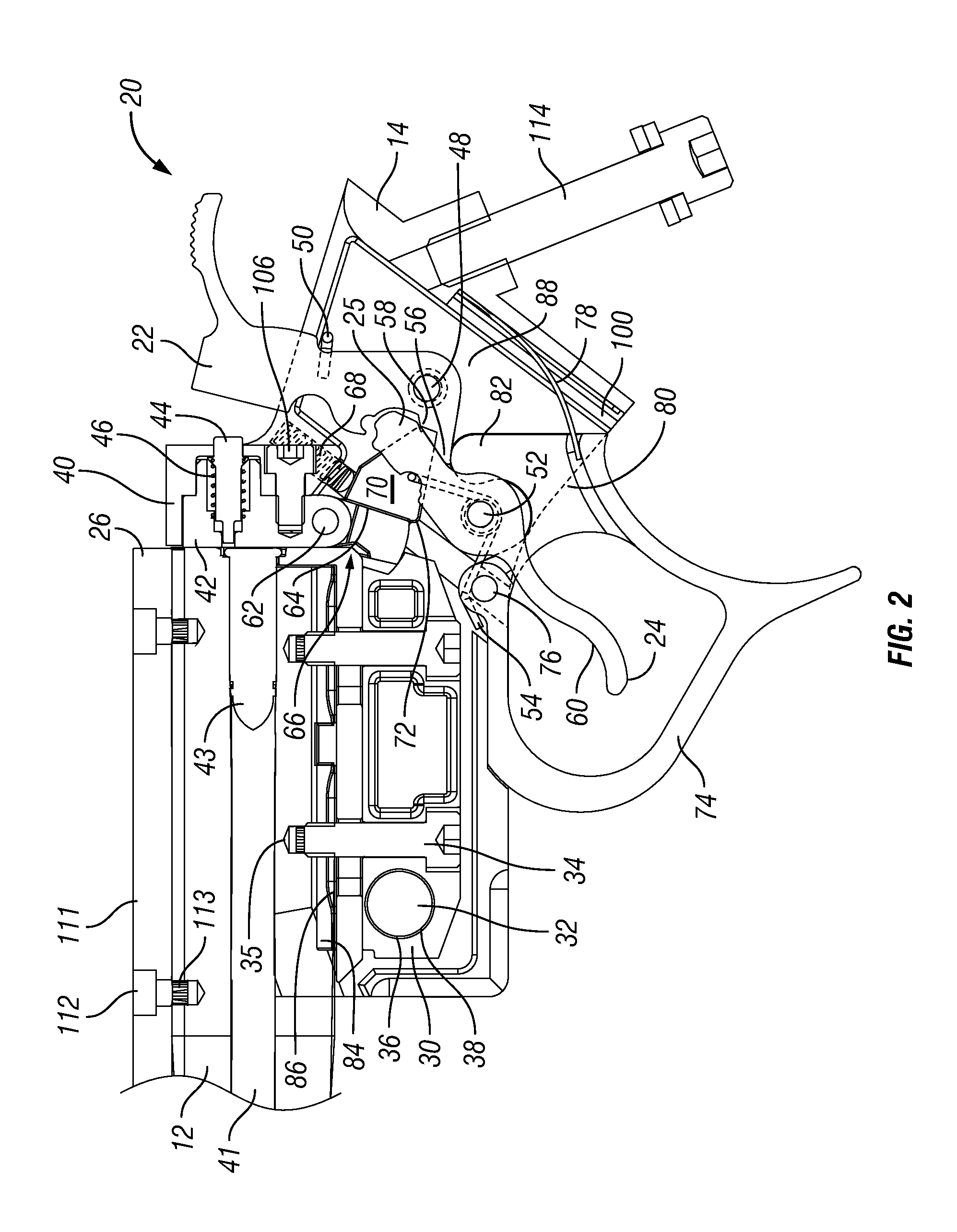

[0022]Referring to FIG. 1, a break action rifle 10 includes a barrel 12, which is pivotally mounted to a receiver 14 that supports a fore end 16 and a stock 18. The receiver also houses a firing mechanism 20, of which a hammer 22 and a trigger 24 are shown in FIG. 1, and a catch mechanism 66 (shown in FIG. 2). The barrel 12 has a breech end 26 and a muzzle end 28.

[0023]Referring to FIG. 2, the barrel 12 is connected to the receiver 14 by way of a barrel tang 30 and a pivot pin 32, located near the barrel breech end 26. The barrel tang 30 is attached to the barrel 12 by bolts 34 threaded into holes 35 tapped into the outer surface of the barrel 12. The barrel tang 30 includes a transverse through hole 36, while the receiver 14 includes transverse holes 38. The pivot pin 32 is inserted through the transverse holes 36, 38 to pivotally mount the barrel 12 to the receiver 14. The barrel 12 is pivotal between a closed position, where the breech end 26 rests against a breech portion 40 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com