Pulsed power supply with parallel high-energy capacitors for electrosparking

A pulse power supply, high-energy technology, applied in the direction of electric processing equipment, metal processing equipment, circuits, etc., can solve the problems of poor discharge uniformity, good thermal conductivity, poor electrical conductivity, etc., and achieve improved power utilization, high instantaneous discharge energy, The effect of improving work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

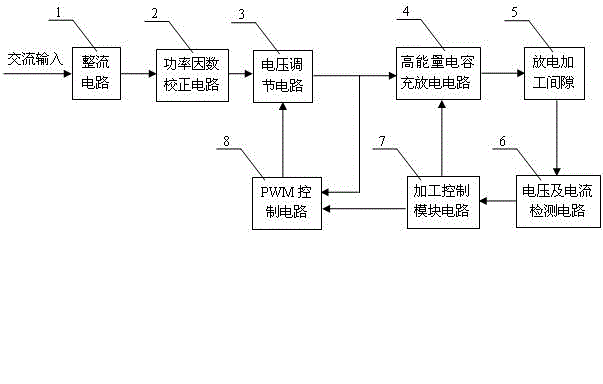

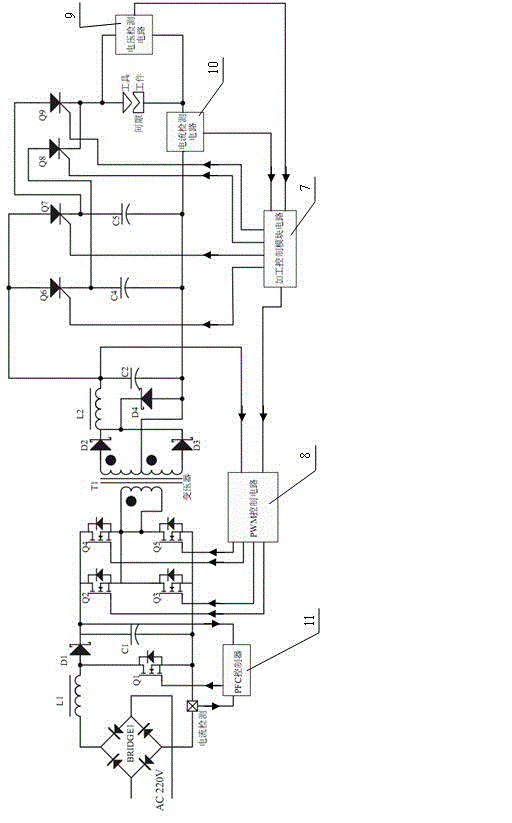

[0018] see figure 1 . The parallel high-energy capacitor EDM pulse power supply of the present invention includes a rectifier circuit 1, a power factor correction circuit 2, a voltage regulation circuit 3, a high-energy capacitor charging and discharging circuit 4, a voltage and current detection circuit 6, a processing control module circuit 7, a PWM control circuit 8. The rectifier circuit 1 converts the alternating current into direct current, and sends it to the power factor correction circuit 2 for power factor correction; the corrected direct current voltage is output to the voltage regulation circuit 3; the voltage regulation circuit 3 automatically adjusts the voltage according to the control command sent by the PWM control circuit 8 , and sent to the high-energy capacitor charging and discharging circuit 4; the high-energy capacitor charging and discharging circuit 4 provides high discharge energy to the discharge machining gap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com