Agitators for wave-making or mixing as for tanks, and pumps and filters

a technology of agitators and pumps, applied in the direction of mixing, rotary stirring mixers, transportation and packaging, etc., can solve the problems of increasing operating costs, reducing system performance, and most of the energy loss in a steady stream

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

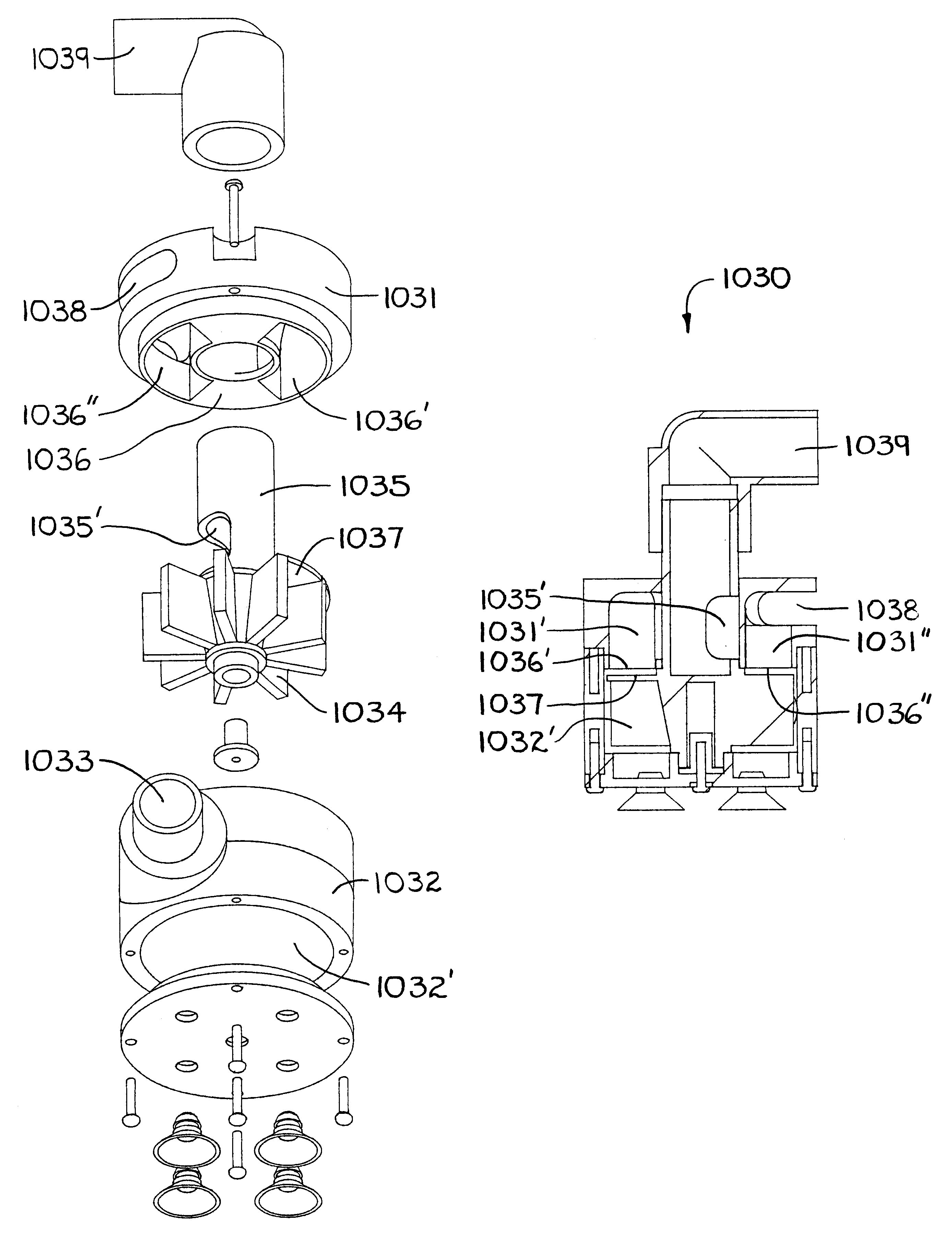

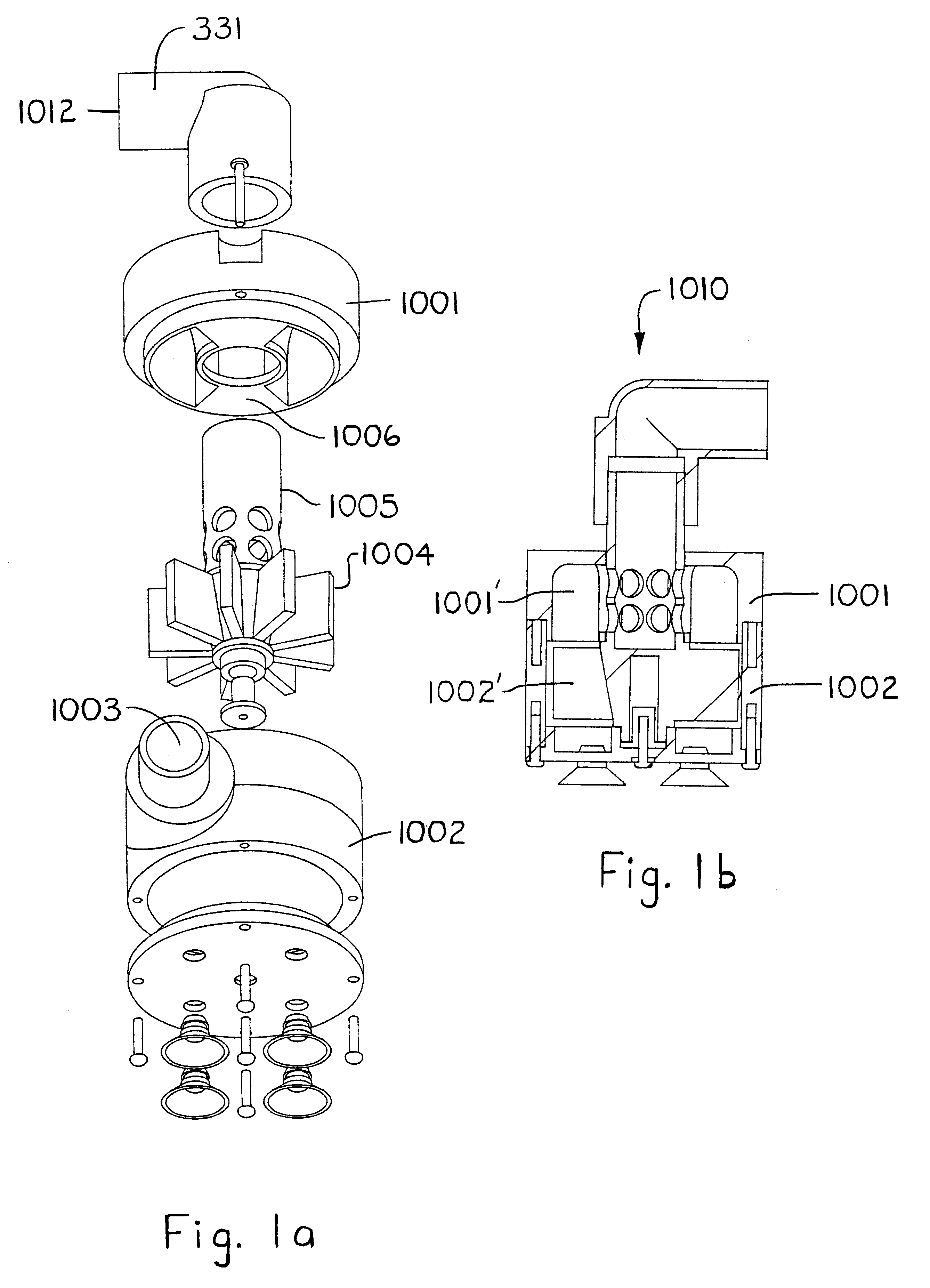

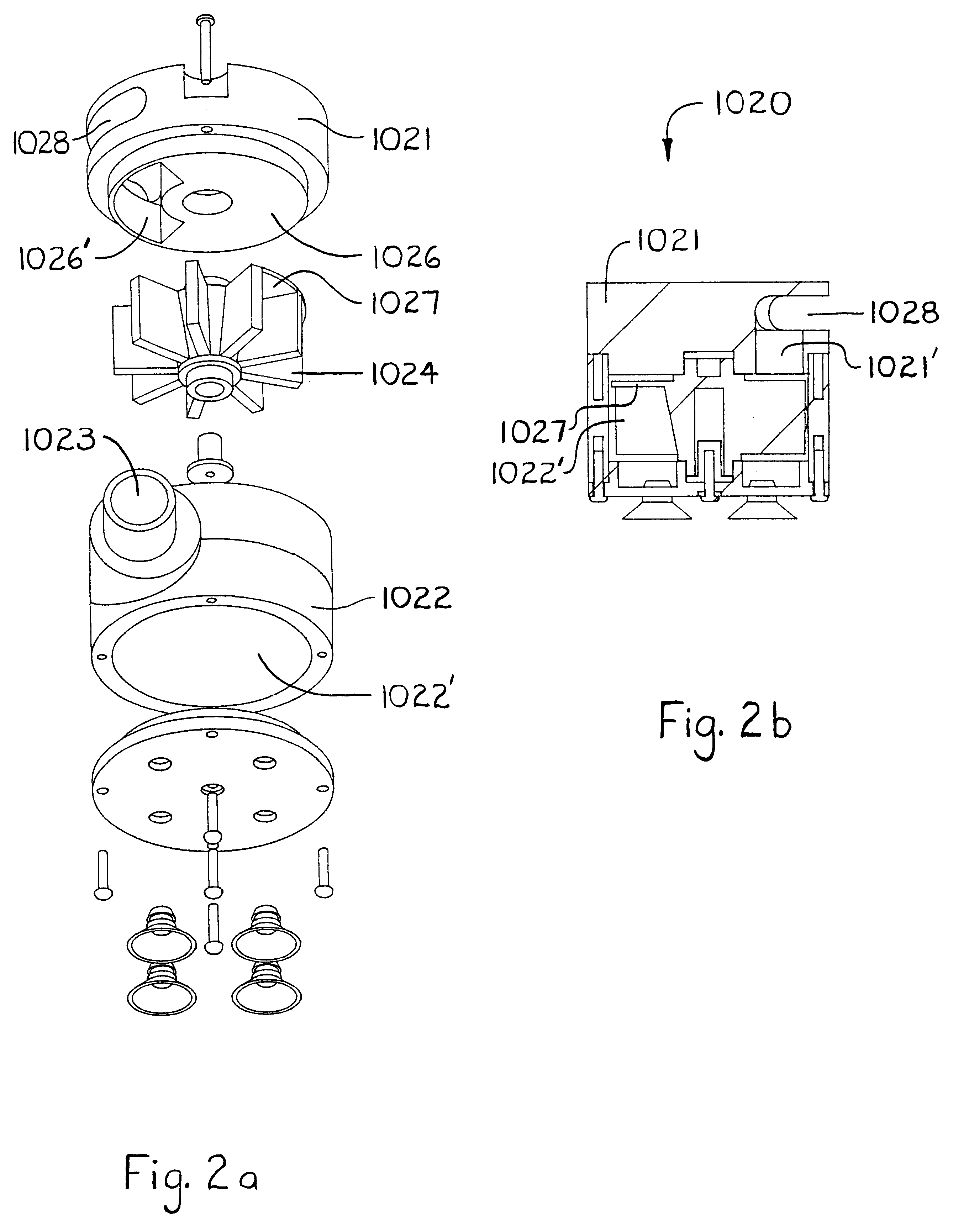

FIGS. 1a and 1b show a rotator 1010 in accordance with the invention. The rotator 1010 includes upper and lower housings 1001 and 1002 which respectively define upper and lower plenums 1001' and 1002'. The lower housing encloses the turbine 1004, which is driven at constant speed by the steady infeed flow entering through the inlet 1003. The turbine 1004 has appended to it a hollow apertured shaft 1005 which extends through the partition wall 1006 between the upper and lower plenums, to couple to a 90.degree.-nozzle forming the discharge port 1012 for this rotator 1010. The 90.degree. discharge port 1012 protrudes out above a top wall of the upper housing 1001. The flowthrough of the infeed stream in the inlet 1003 causes the turbine 1004 to spin. The spinning turbine 1004 spins the directly coupled 90.degree. discharge port 1012 through complete rotations. The infeed stream flows up out of the vanes of the turbine 1004, into the upper plenum 1001', into the lumen of the hollow shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com