Titanium sponge 10-ton reduction-distillation furnace

A technology of sponge titanium and steaming furnace, applied in the field of steaming furnace and sponge titanium recovery, can solve the problems of long welding seam, increase maintenance cost and labor intensity, affect magnesium chloride, etc., and achieve obvious economic effect, good thermal insulation effect and reasonable production capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

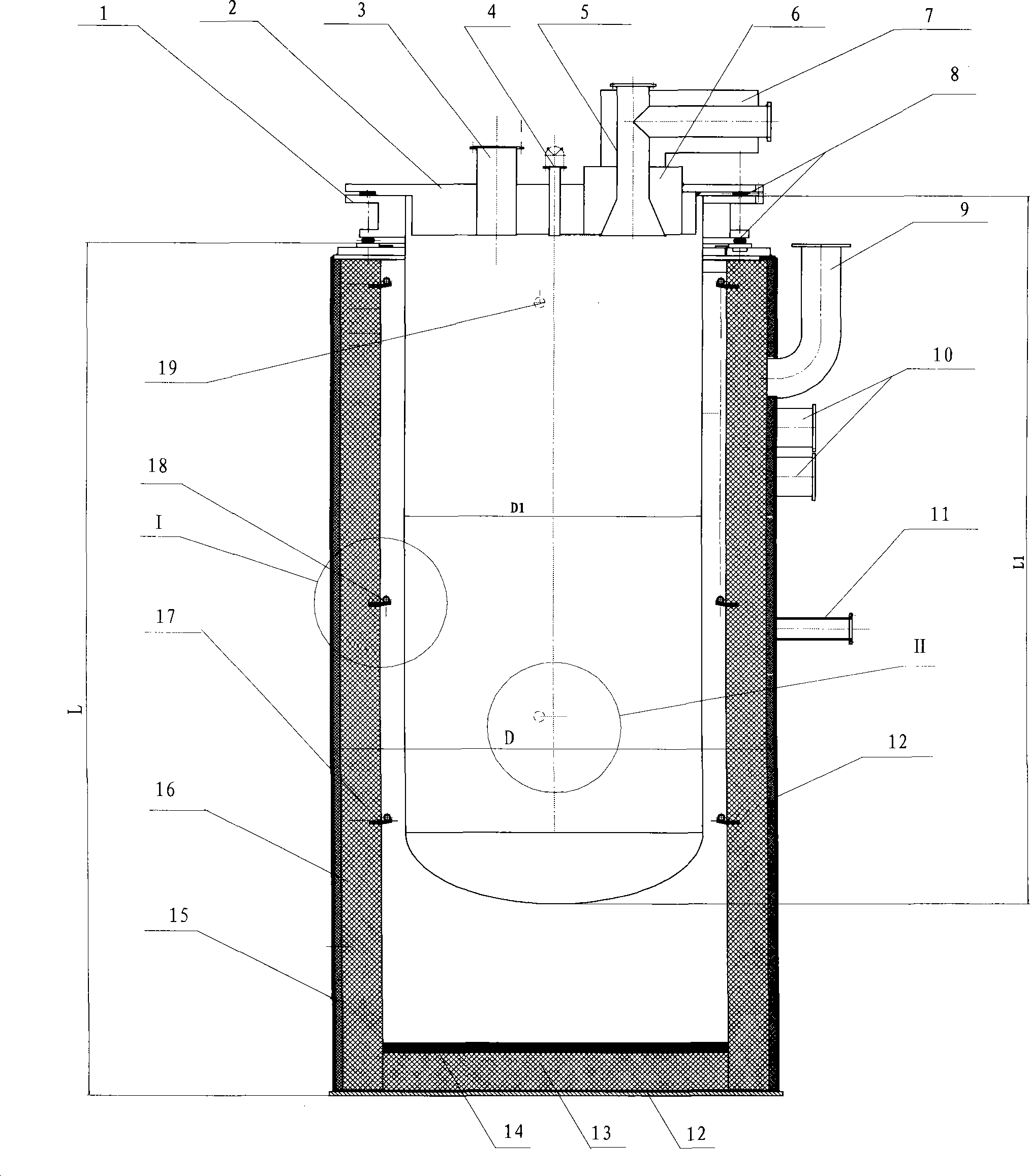

[0020] combine figure 1 , 10 tons of sponge titanium of the present invention combined return-steam furnace mainly is made of U-shaped reactor (1), reaction cover (2), furnace body (16), conductive device (17), wherein U-shaped reactor (1) The ratio of the length to the diameter is 2.43, and the ratio of the length to the diameter of the body of heater (16) is 1.94. The U-shaped reactor (1) is vertically installed in the body of heater (16), and the flange of the U-shaped reactor (1) Carried on the body of furnace (16) and sealed by a sealing ring (8), a reaction cover (2) is added to the upper end of the U-shaped reactor (1).

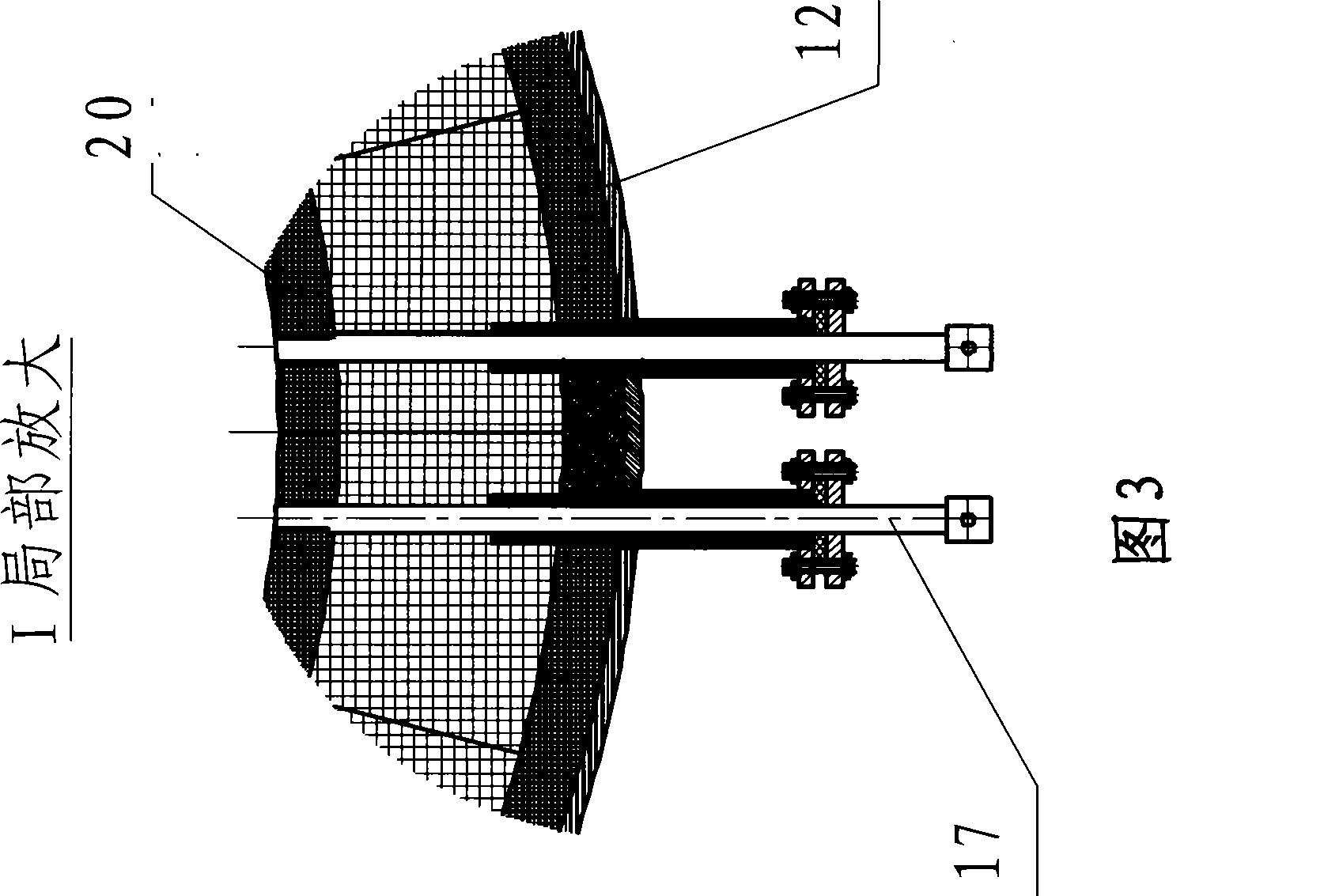

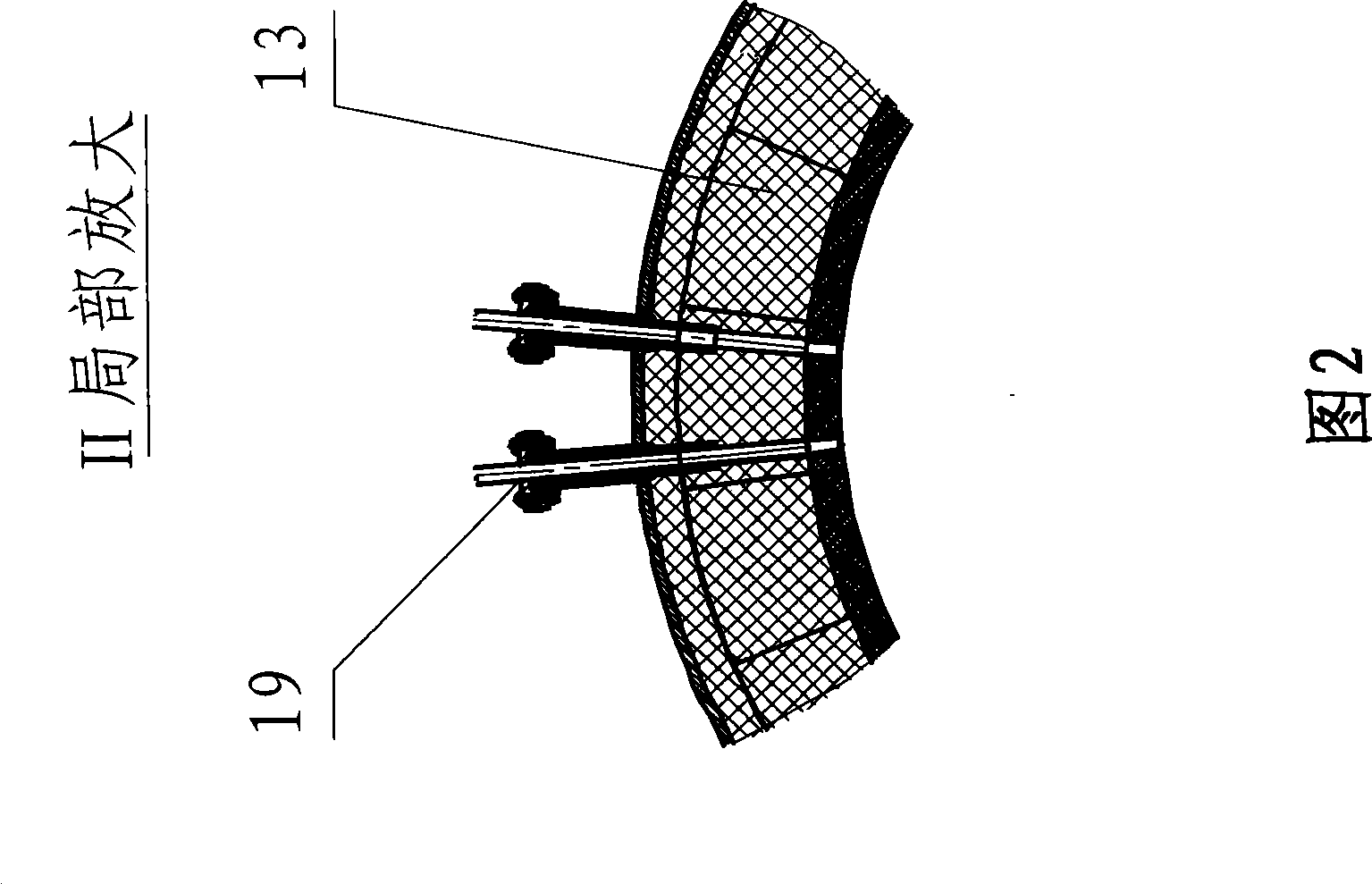

[0021] 10 tons of sponge titanium combined return-steam furnace of the present invention, its body of furnace (16) is made of air outlet pipe (9), air inlet pipe (10), evacuation pipe (11), asbestos board (12), high aluminum light weight Insulation brick (13), heat insulation magnesia brick (14), vacuum fiber block (15), conductive device (17), heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com