Automobile front floor framework

A car front floor and frame technology, applied to vehicle parts, upper structure, upper structure sub-assembly, etc., can solve the problems of driver and front passenger's calf threat, passenger cabin structural deformation, and insufficient overall rigidity, etc., and achieve reduction Compression of living space, improvement of mechanical noise, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

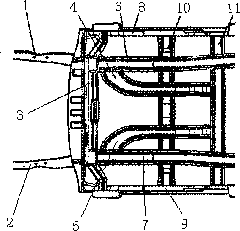

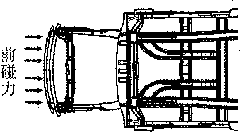

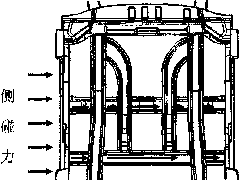

[0016] Such as figure 1 As shown, the front floor frame of the automobile in this embodiment is formed by overlapping the front beam 3, the left longitudinal beam 7, the right longitudinal beam 6, the left door sill inner panel 9, the right door sill inner panel 8 and the rear beam 11 to form a "mesh" shaped frame structure. , the front part of the front beam 3 is overlapped with the left front beam 2 and the right front beam 1, and the key point is that it also includes the left middle beam 5, the right middle beam 4 and the front beam 3 and the rear beam 11. The middle cross beam 10, the front ends of the left middle longitudinal beam 5 and the right middle longitudinal beam 4 are bent into a certain arc, and are respectively lapped on the front ends of the left longitudinal beam 7 and the right longitudinal beam 6, that is, the left longitudinal beam 7 and the right longitudinal beam 6 The position overlapping with the front beam 3, the rear ends of the left middle longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com