Solar facility of high industrial production line of forage grass, vegetable, flower and medical material

A solar energy and production line technology, applied in agricultural machinery and equipment, renewable energy machines, botanical equipment and methods, etc., can solve problems such as low yield, insufficient light, and inability to ensure harvest.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

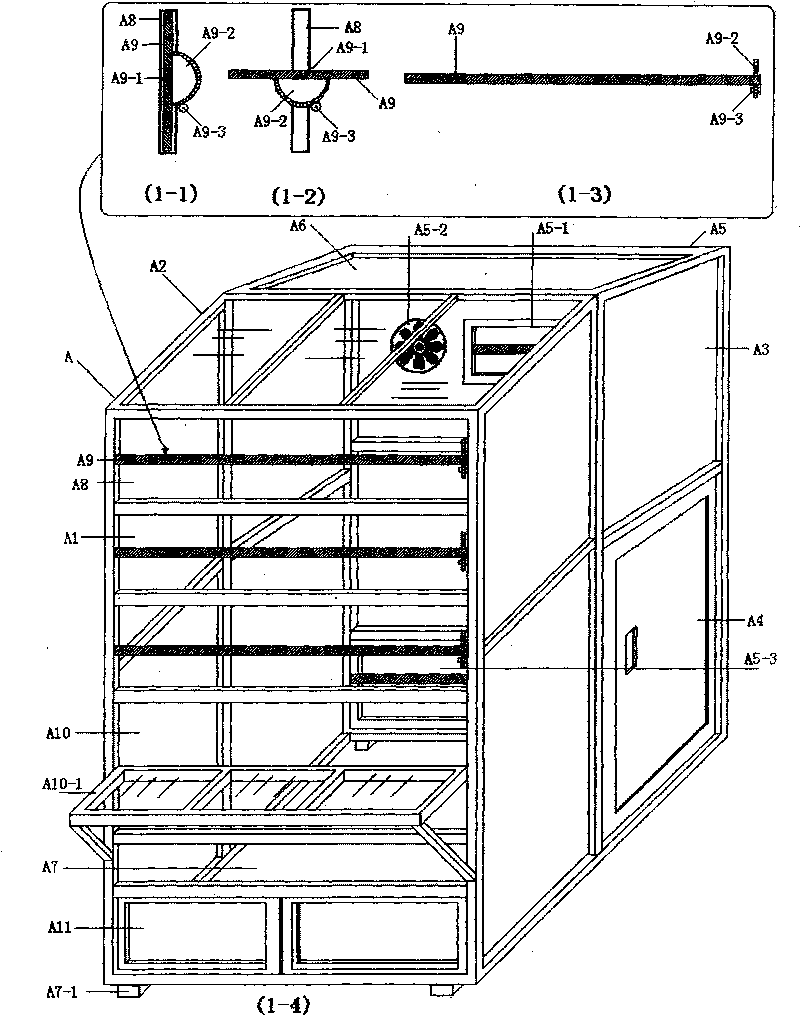

[0049] exist figure 1 Middle: (A) Thermal insulation production room, (A1) Sunny front wall, (A2) Sunny inclined roof, (A3) Thermal insulation right wall, (A4) door, (A5) Backlit back wall, (A5-1) Upper thermal insulation and ventilation Window, (A5-2) Exhaust fan, (A5-3) Lower insulation ventilation window, (A6) Insulation top cover, (A7) Insulation floor, (A7-1) Foot, (A8) Translucent window frame, (A9) ) electric opening and closing window, (A9-1) center shaft, (A9-2) semicircular tooth, (A9-3) window DC brushless motor, (A10) cultivation tray harvesting window, (A10-1) cultivation tray platform, (A11) Edible mushroom harvest window.

[0050] In the figure: (A2) sunlight slanted roof connected sequentially by (A1) sunlight front wall, (A3) heat preservation right wall and (A4) door connected with interior and (A5) backlight rear wall connected with interior (A5) -1) Thermal insulation ventilation window and (A5-2) exhaust fan are connected with (A5-3) lower thermal insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com