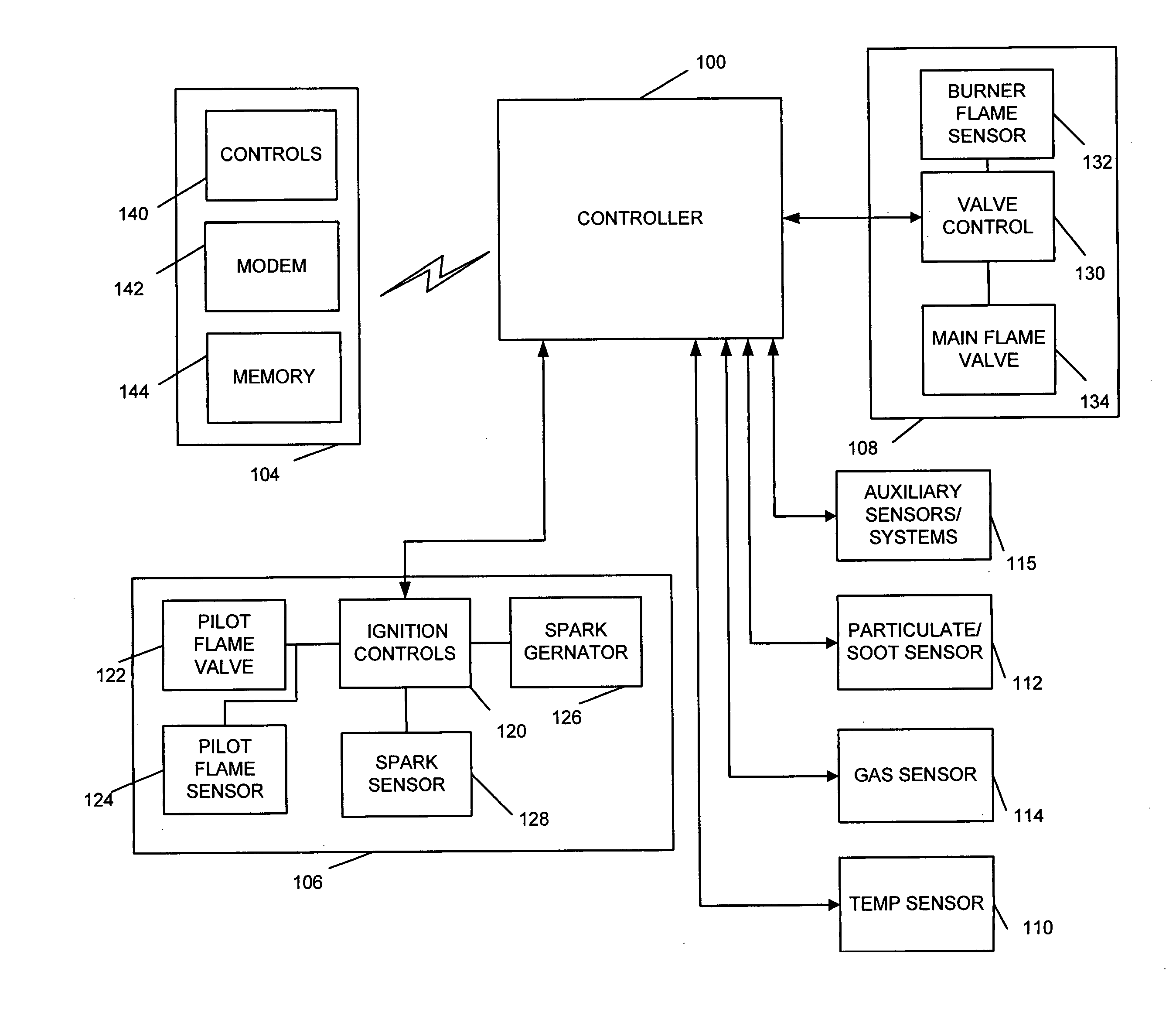

Gas fireplace monitoring and control system

a technology for monitoring and controlling systems and gas fireplaces, applied in the direction of gaseous heating fuel, stoves or ranges, ways, etc., can solve problems such as safety and maintenance problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

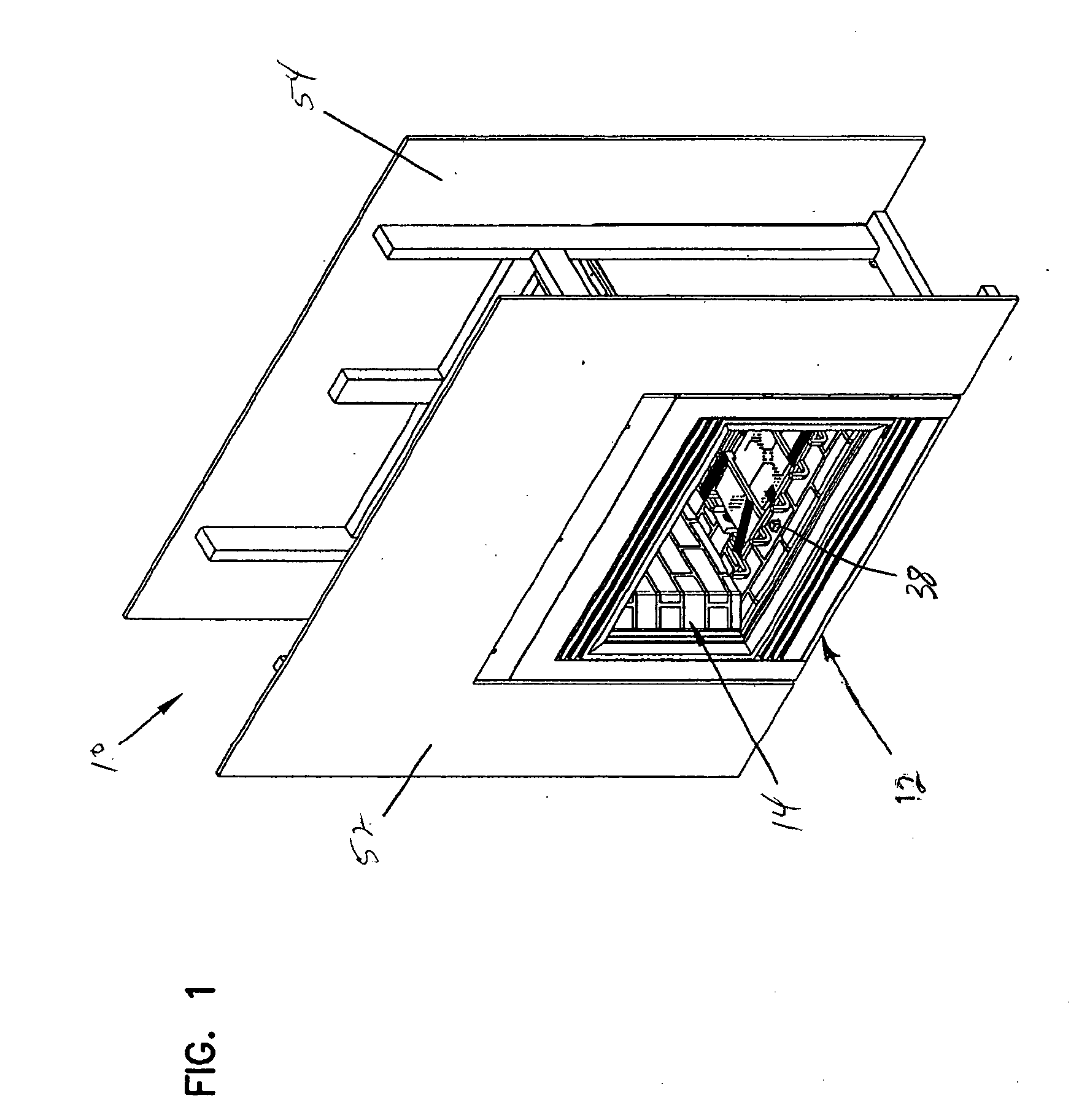

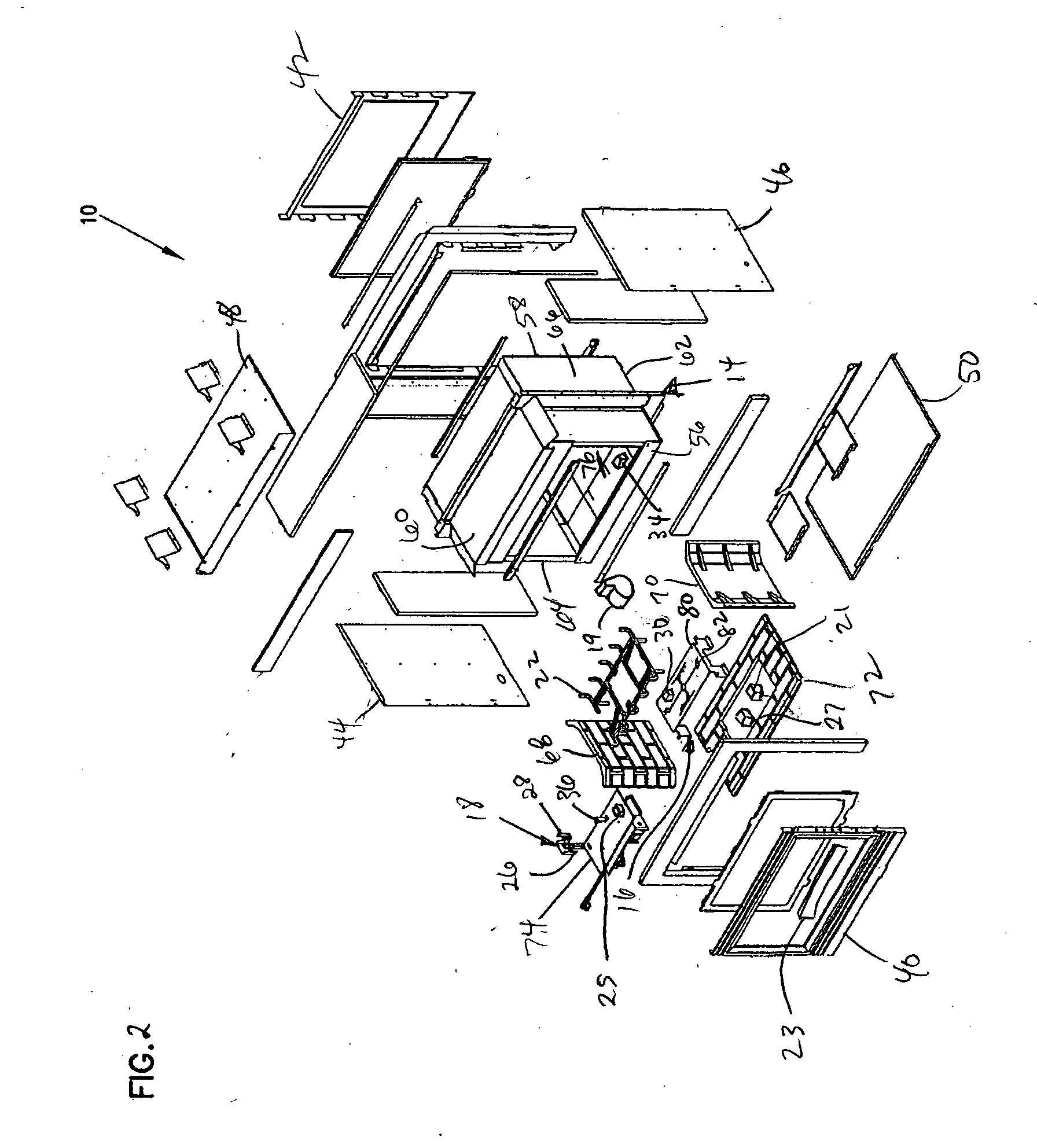

Image

Examples

example 1

[0057] 1. A fault is tripped on the controller by the fireplace actions. [0058] 2. The controller checks the telephone line to see if it is being used, and if so waits a set amount of time after it is not used before dialing. [0059] 3. If / when the line is not in use, the controller performs any action necessary to reach an outside line. [0060] 4. The controller then dials the designated phone number to reach the remotely located computer system. [0061] 5. The receiving computer system picks up and waits for ready to send code from the fireplace controller. [0062] 6. The receiving computer system hears a “ready to send” code and transmits “ready to receive” code. [0063] 7. After hearing the ready to receive code, the fireplace controller sends the serial number with a coded signal indicating the fault code and other information about the fireplace. [0064] 8. When the transmission of information is completed, the fireplace controller will then wait until it hears the received successf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com