Patents

Literature

216results about "Detergent preparation by chemical means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

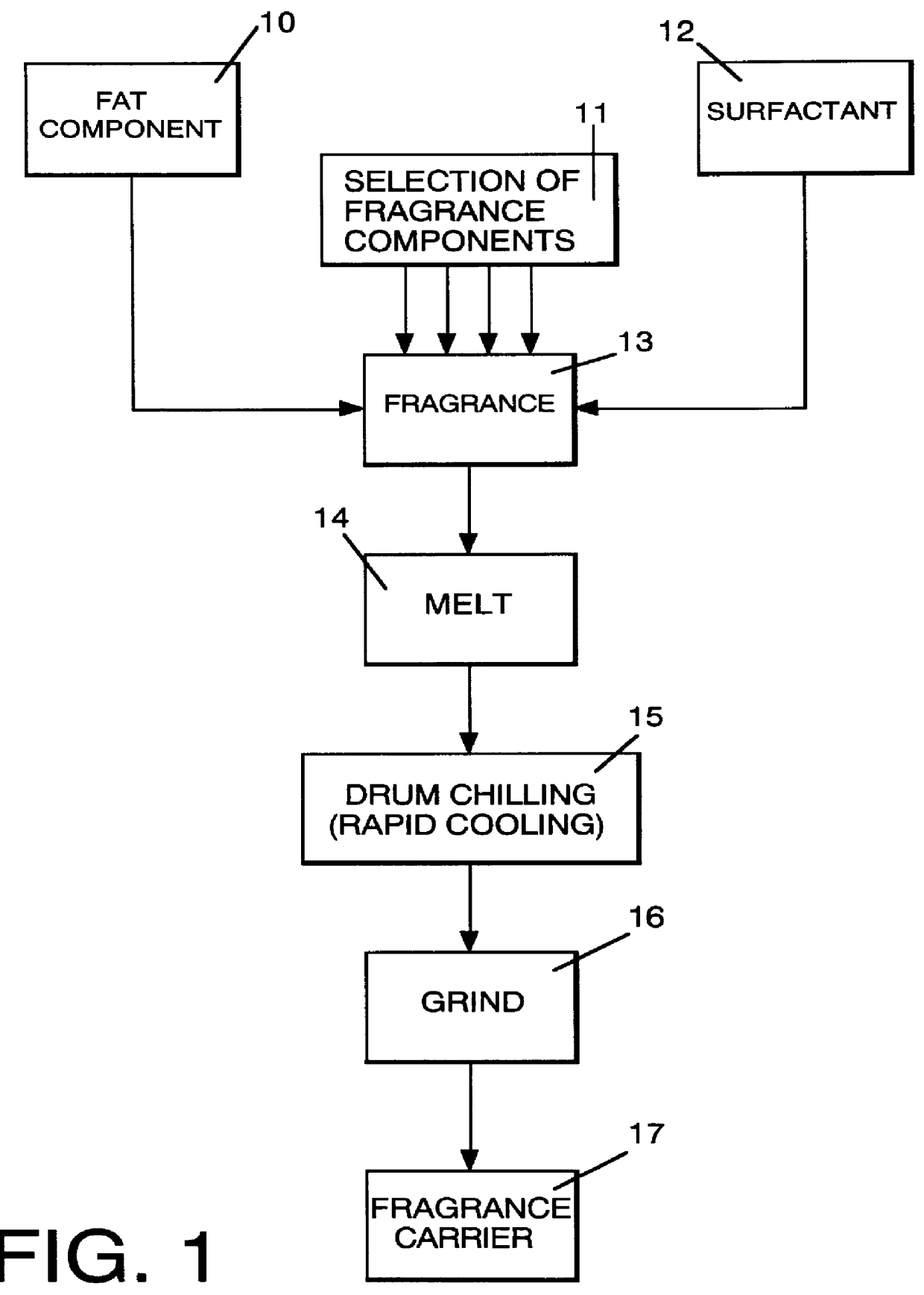

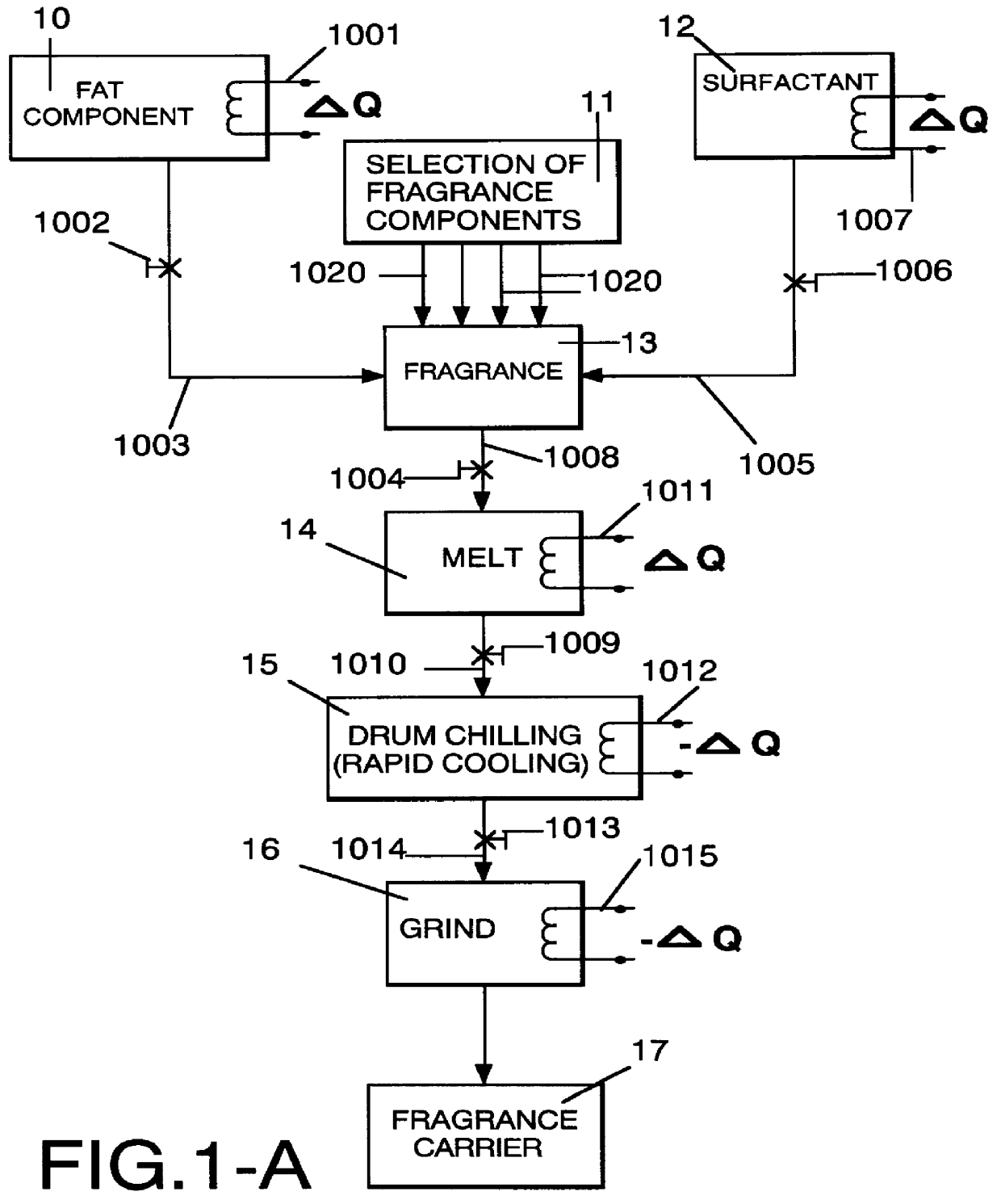

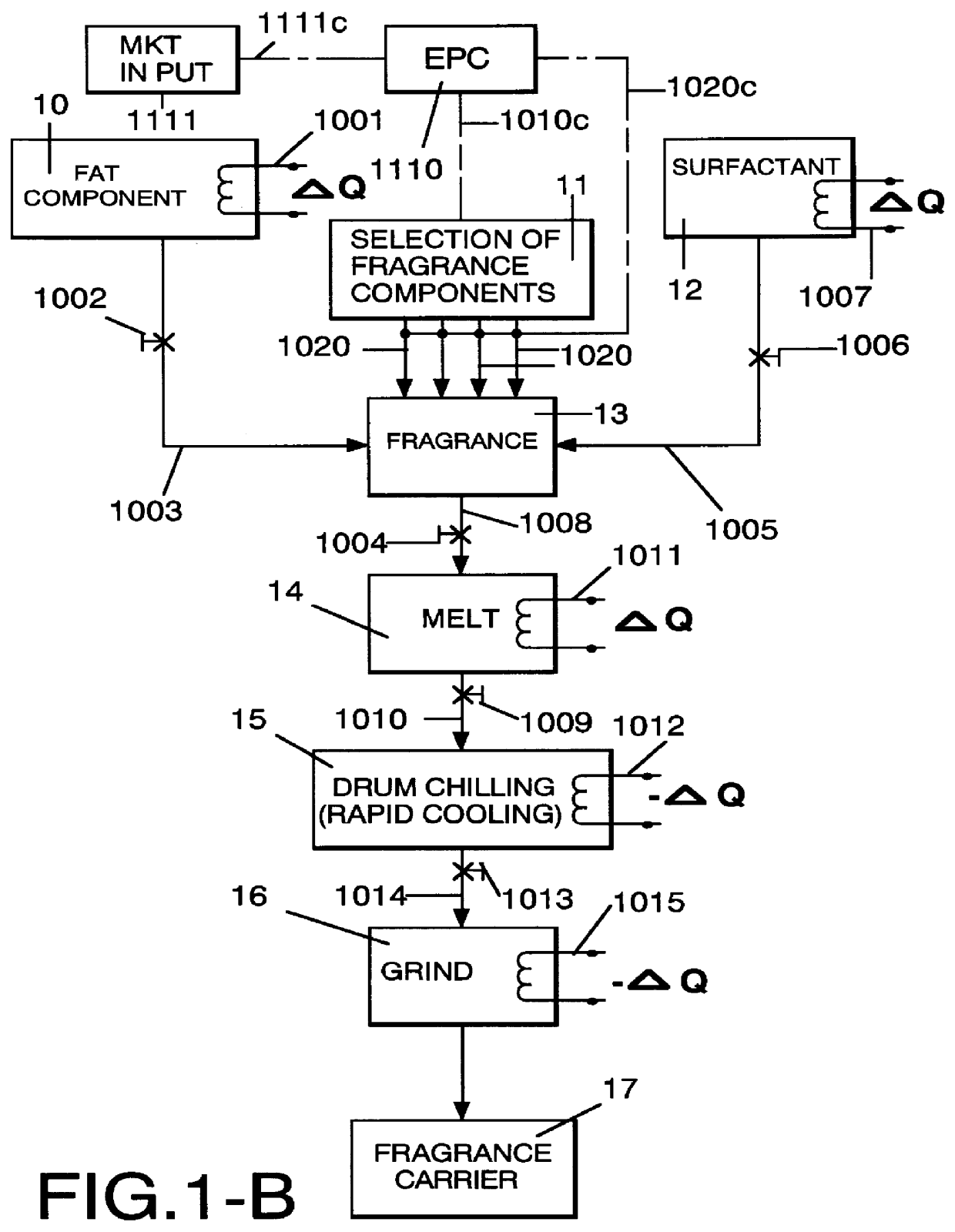

Method employing drum chilling and apparatus therefor for producing fragrance-containing long lasting solid particle

InactiveUS6051540AImproved substantivityMaximum flexibilityNon-ionic surface-active compoundsGaseous substancesDesiccantSolid particle

A method and apparatus is disclosed for producing a fragrance-containing solid particle, capable of controllably releasing the fragrance to the environment in which the particle is contained for incorporation into laundry detergents, fabric softener compositions and drier-added fabric softener articles.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

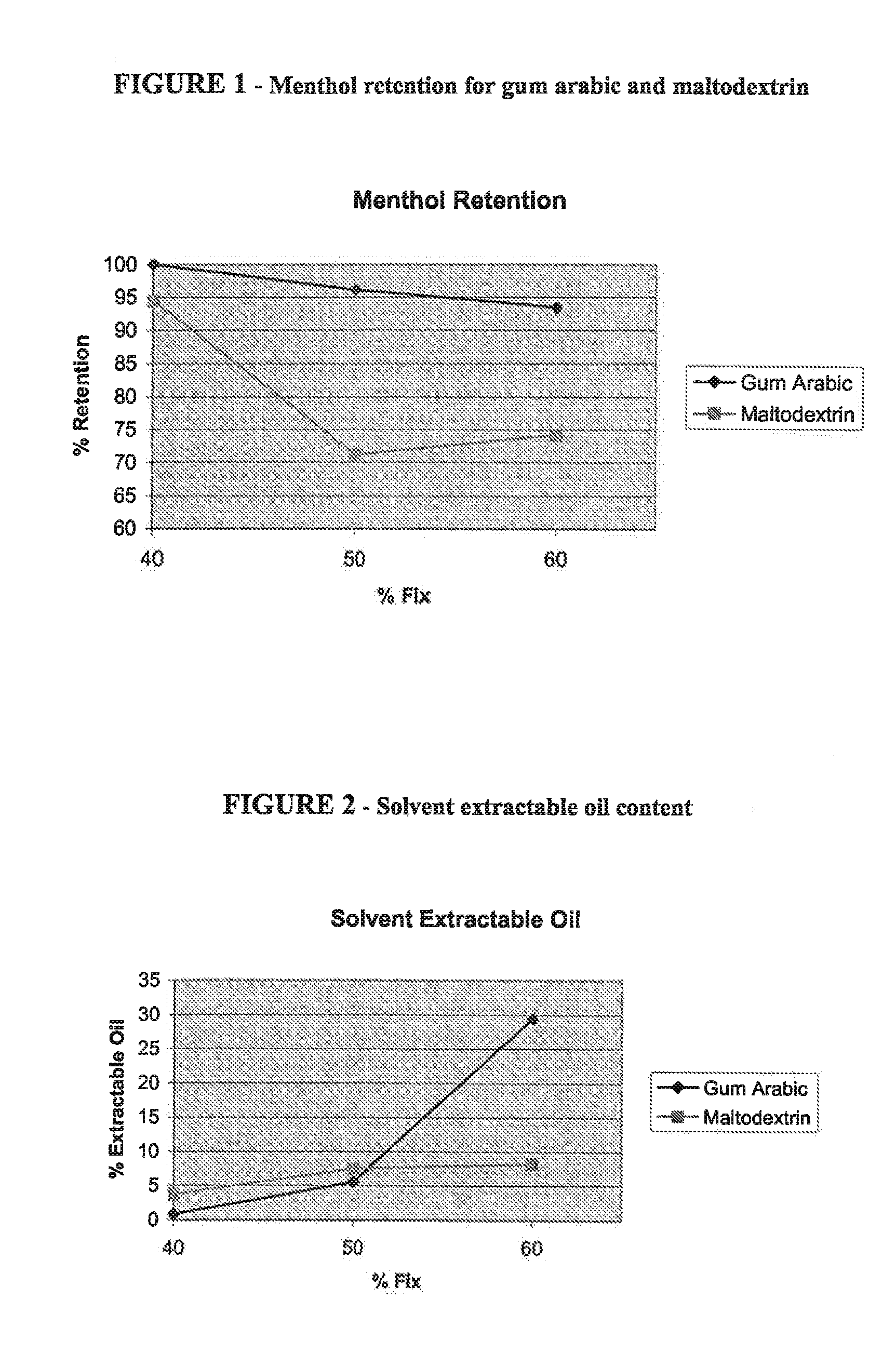

Spray-Dried Compositions and Their Uses

InactiveUS20140056836A1Minimize impactCosmetic preparationsSurface-active detergent compositionsMentholBULK ACTIVE INGREDIENT

The present invention relates to spray dried compositions of one or more active ingredients dispersed in a carrier of gum Arabic in admixture with a non-ionic surfactant. The compositions are particularly useful for the encapsulation of menthol and can be used to prepare chewing gums and compressed tablets.

Owner:FIRMENICH SA

Article for use in washing in sheet form

InactiveUS6818606B1Improve solubilityDetergent preparation by chemical meansDetergent powders/flakes/sheetsSolubilityWater soluble

Owner:KAO CORP

Process for the production of detergent granules

InactiveUS7053038B2Fine granularityPreventing aggregation and cakingInorganic/elemental detergent compounding agentsPigmenting treatmentCarbonationSURFACTANT BLEND

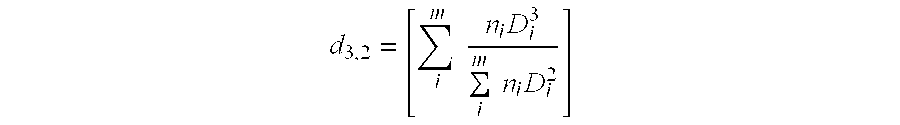

A low shear mechanical granulation process for the production of detergent granules, the process comprising contacting an acid precursor of an anionic surfactant, a non-surfactant acid and a solid carbonated neutralising agent wherein the solid carbonated neutralizing agent has a d3,2 average particle size no more than 90 μm, preferably no more than 80 μm, more preferably no more than 70 μm, still more preferably no more than 60 μm, yet more preferably no more than 50 μm and especially no more than 40 μm.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Spray dried enzyme product

InactiveUS6924133B1Simple and cost-effective processMaintain good propertiesPowder deliveryOrganic detergent compounding agentsSolid particleFermentation broth

The invention relates to a particle comprising an enzyme and a biomass, to a process for preparing a particle comprising spray drying an enzyme and biomass containing fermentation broth starting material, to obtain a solid particle comprising an enzyme and a biomass and to a process for preparing an enzyme containing particle comprising spray drying an aqueous enzyme containing liquid starting material to obtain a spray dried first enzyme containing particle and subsequently subjecting the first dry particle to a process selected from granulation and coating and combinations thereof to obtain a second dry enzyme containing particle.

Owner:NOVOZYMES AS

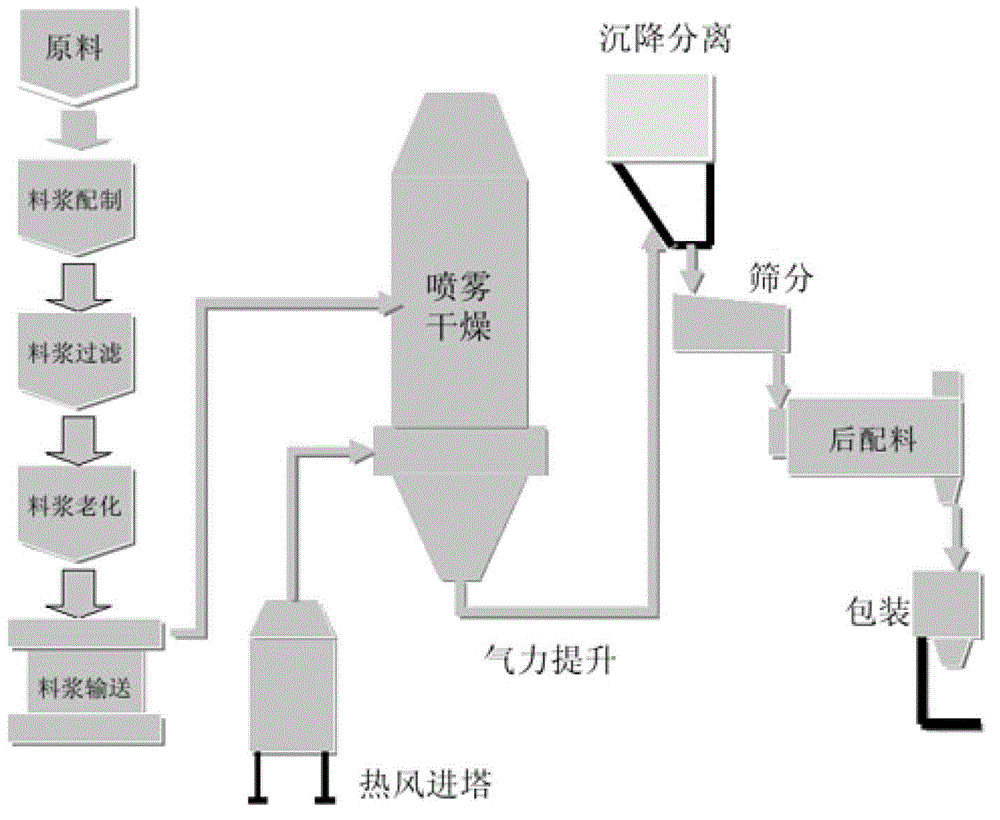

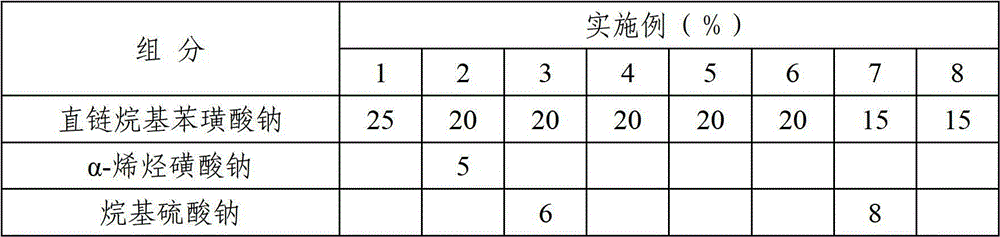

Neutral washing powder and preparation method thereof

ActiveCN102876489AStrong decontaminationImprove liquidityOrganic detergent compounding agentsNon-ionic surface-active compoundsOrganic acidSolubility

The invention provides a neutral washing powder with a new compound formula. The washing powder contains neutralizing agents and powder spraying and forming auxiliaries, namely organic acids and does not contain such alkaline materials as sodium silicate and sodium carbonate. The washing powder can effectively protect fabric fibers, care clothes, is truly inirritative in hand washing, has good dissolubility, is quickly dissolved under low temperature and adopts the spray drying production process. The specific feeding sequence is adopted during slurry mixing, so that the washing powder particles with moderate strength and good flowability can be produced with the formulas under the conditions of high active agent system and absence of powder spraying skeleton sodium silicate materials. The washing powder has strong detergency under neutral condition and achieves the effect of washing and caring unification.

Owner:NICE GROUP

Spray dried powdered detergents with perfume-containing capsules

The present invention relates to a process for the manufacture of a spray dried powder comprising:(a) forming a warm, stirred aqueous slurry comprising: inorganic salts, at least one binding agent and 0.001 to 20% by weight of capsules based on the weight of spray dried powder, said capsules containing benefit agents including at least perfume, and(b) spray drying the resultant slurry to form a spray dried powder, said capsules being such that:1) more than 40% of the benefit agents remain encapsulated 60 minutes after dispersion thereof at 70° C. in the slurry as defined in the “slurry survival test” in a sealed vessel without agitation; and2) more than 30% of the benefit agents added for 15 minutes to an ambient slurry as defined in the “spray dry test” survive spray drying through a laboratory scale spray drier.

Owner:TAKASAGO INTERNATIONAL CORPORATION

Calcium hypochlorite/scale inhibitor/residue disperser triblend

InactiveUS7410938B2Reduced scale depositsObstruct passagewayInorganic/elemental detergent compounding agentsDetergent bleaching agentsPhosphateCalcium hypochlorite

A solid calcium hypochlorite composition comprising a mixture of: solid calcium hypochlorite; a scale-inhibiting effective amount of a primarily scale-inhibiting alkali metal phosphate; and an effective residue-dispersing amount of primarily residue-dispersing alkali metal phosphate.

Owner:INNOVATIVE WATER CARE LLC

Detergent composition

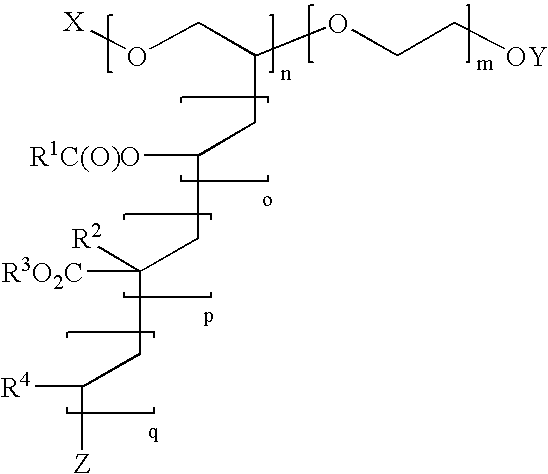

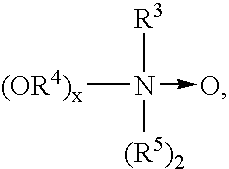

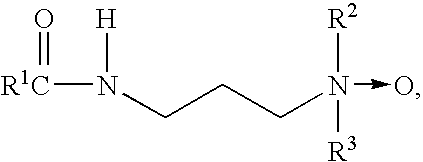

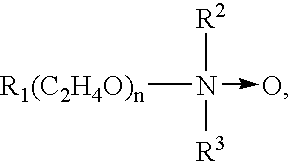

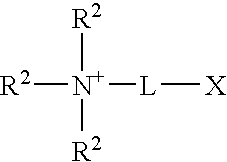

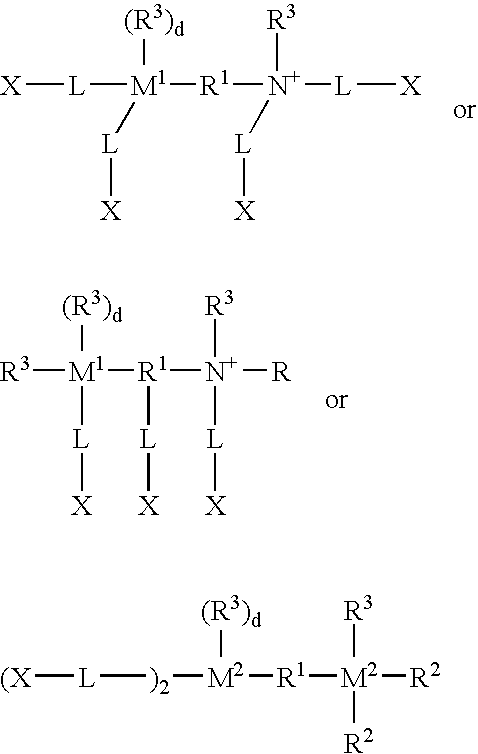

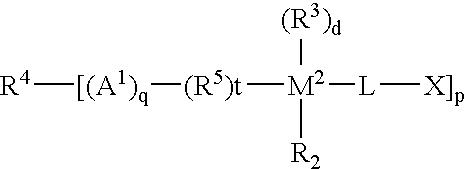

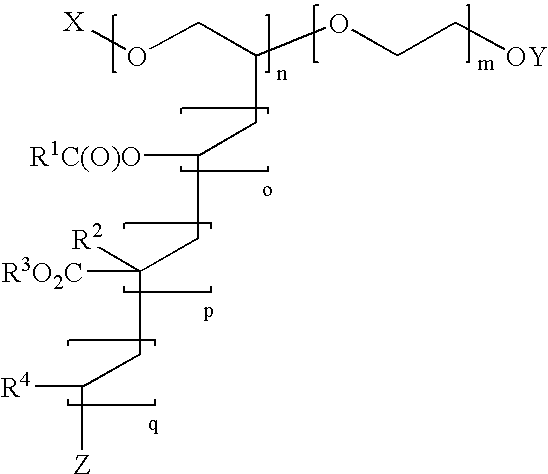

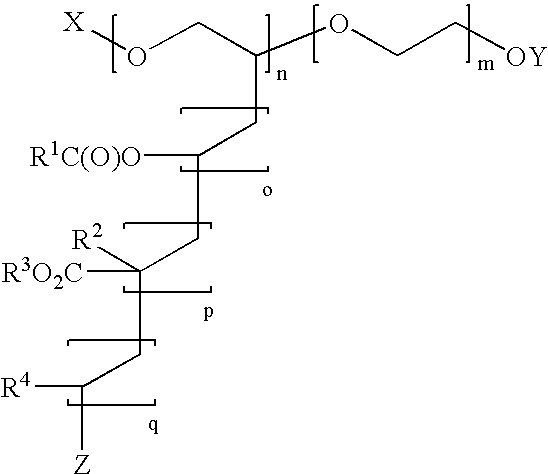

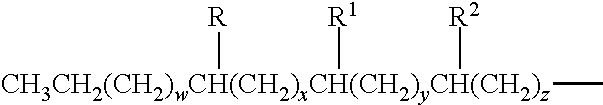

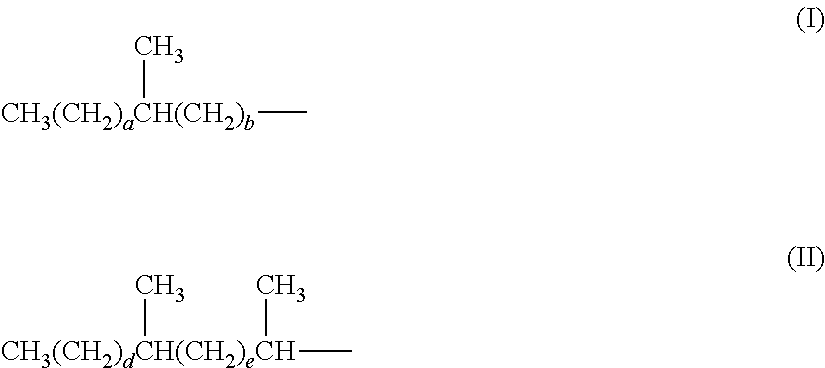

InactiveUS20070281879A1Speed up the processReduce liquid viscosityOrganic detergent compounding agentsDrying soapPendant groupSpray drying

A detergent auxiliary composition comprising from 0.001 wt % to 99 wt % cleaning polymer having a hydrophilic backbone and at least one hydrophobic pendant group, and an adjunct ingredient in which the hydrophilic backbone constitutes less than 50%, preferably less than 45% by weight of the polymer. The detergent auxiliary composition may be, for example a spray-dried particle or an agglomerate. Also described are detergent compositions comprising the detergent auxiliary composition.

Owner:THE PROCTER & GAMBLE COMPANY

Process for forming a low density detergent granule

ActiveUS20060069007A1Lower levelHigh strengthInorganic/elemental detergent compounding agentsDetergent preparation by chemical meansHydrotropePhosphate

A process for forming a low density detergent granule has the steps of providing from about 0.1% to about 6% of a hydrotrope, providing from about 22% to about 50% crutcher mix moisture, providing from about 0.2% to about 8% of a water-soluble polymer with a molecular weight of at least about 10,000 g / mol, providing from about 2% to about 20% sodium silicate having a SiO2:NaO ratio of at least about 2r, and the balance of adjunct crutcher ingredients, mixing the hydrotrope, crutcher mix moisture, polymer, silicate, and adjunct crutcher ingredients in a crutcher to form a slurry, injecting a gas into the slurry at a pressure of from about 6,000 kPa to about 13,000 kPa, and at a rate of from about 0.01% to about 0.25% and forming the slurry into a detergent granule. The slurry is substantially free of zeolite builder and phosphate builder and the crutcher temperature is maintained at from about 40° C. to about 95° C.

Owner:THE PROCTER & GAMBLE COMPANY

Spray drying

InactiveUS20070149423A1Organic detergent compounding agentsDrying soapInorganic saltsLaboratory scale

The present invention relates to a process for the manufacture of a spray dried powder comprising: (a) forming a warm, stirred aqueous slurry comprising: inorganic salts, at least one binding agent and 0.001 to 20% by weight of capsules based on the weight of spray dried powder, said capsules containing benefit agents including at least perfume, and (b) spray drying the resultant slurry to form a spray dried powder, said capsules being such that: 1) more than 40% of the benefit agents remain encapsulated 60 minutes after dispersion thereof at 70° C. in the slurry as defined in the “slurry survival test” in a sealed vessel without agitation; and 2) more than 30% of the benefit agents added for 15 minutes to an ambient slurry as defined in the “spray dry test” survive spray drying through a laboratory scale spray drier.

Owner:TAKASAGO INTERNATIONAL CORPORATION

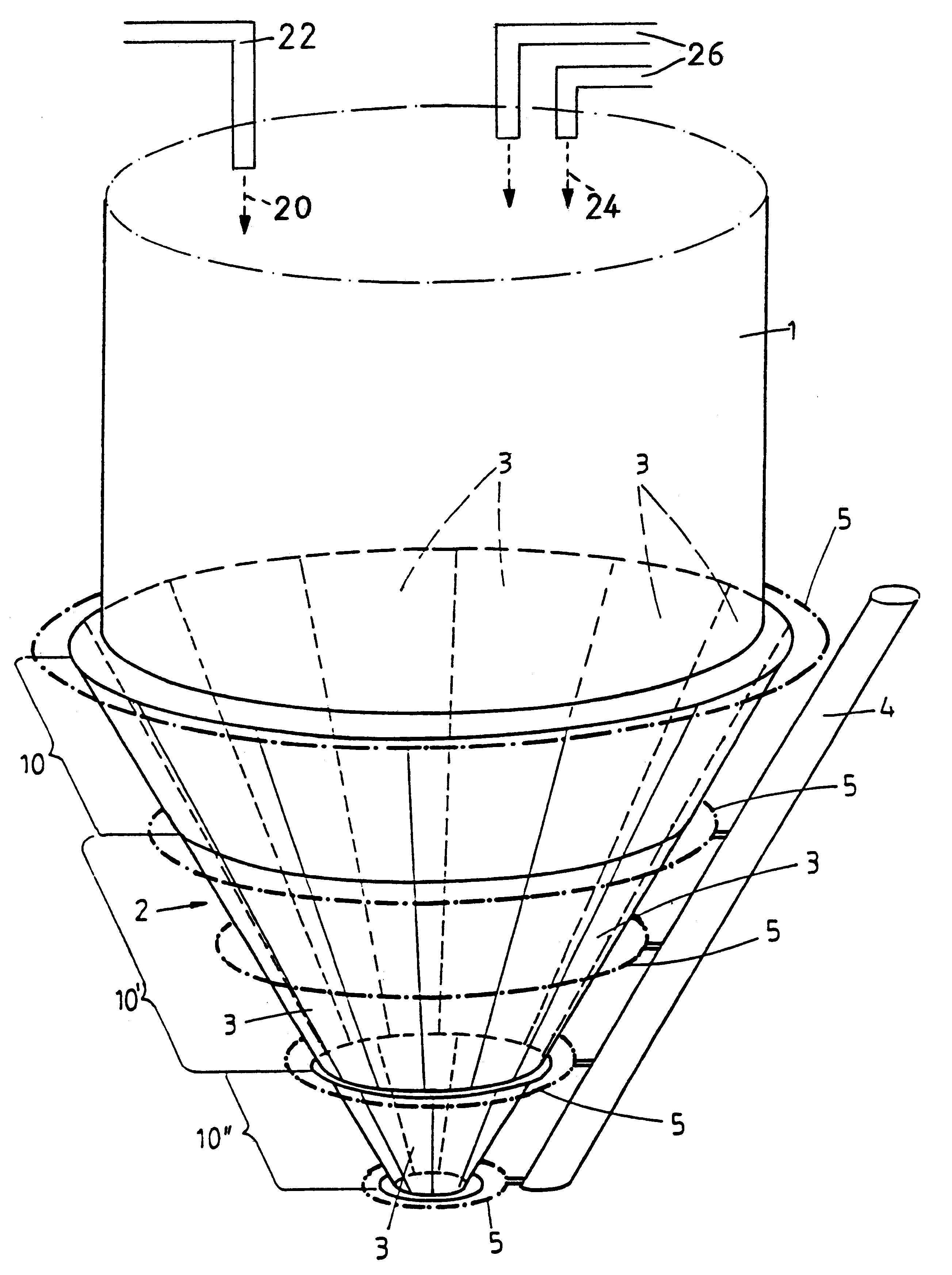

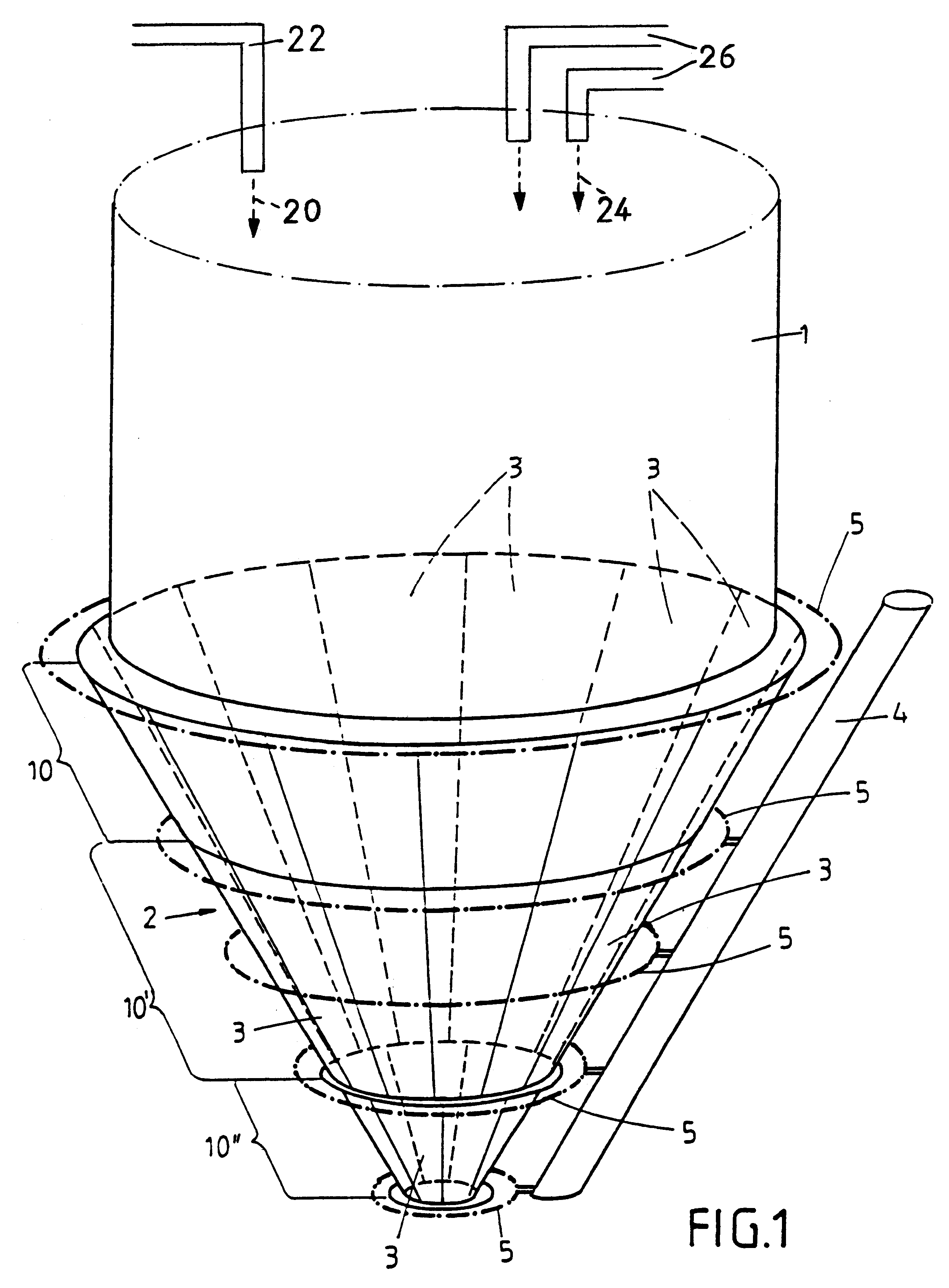

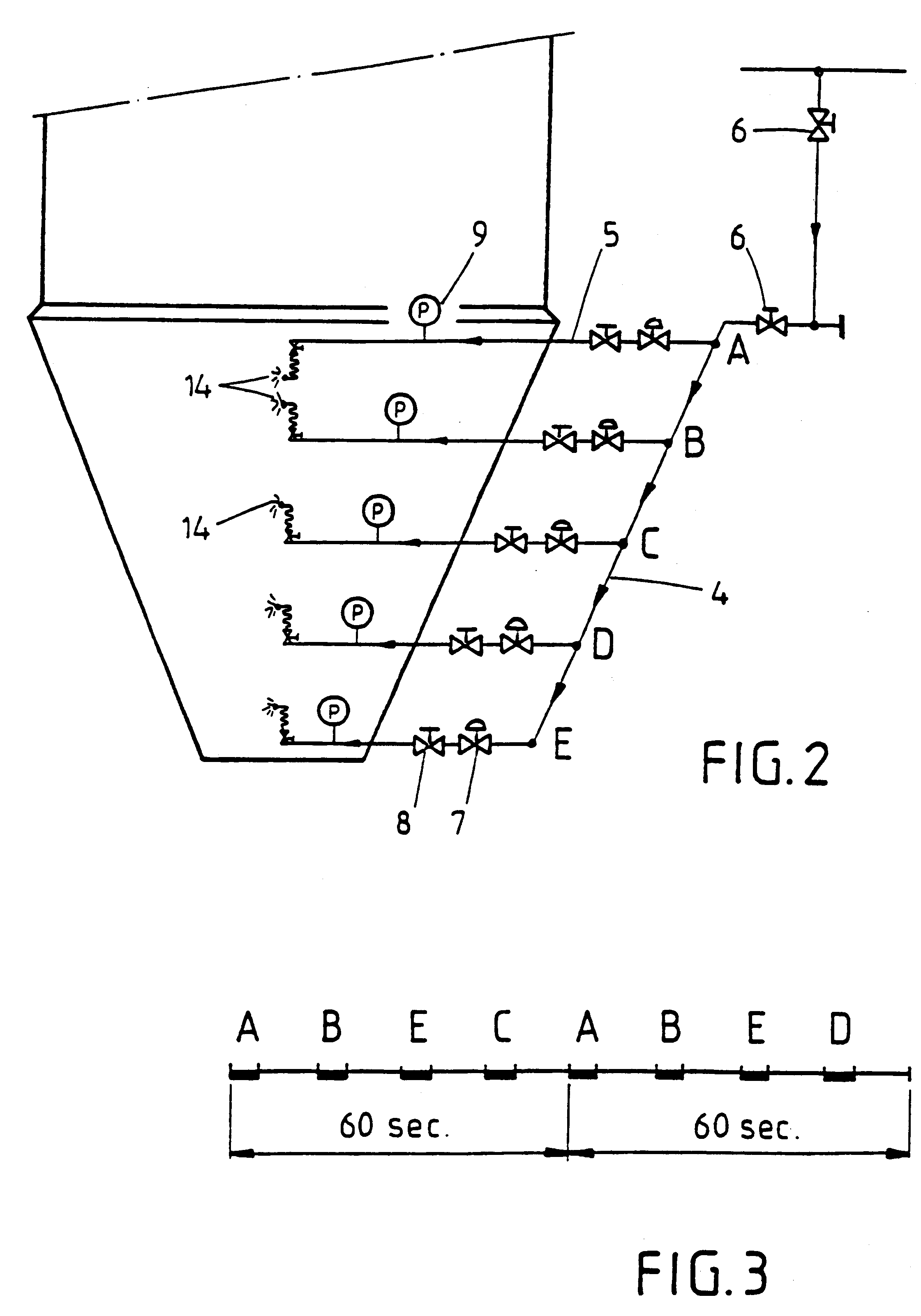

Apparatus and method for a spray dryer

InactiveUS6237247B1Easy to cleanImprove performanceDrying solid materials with heatDetergent preparation by chemical meansEngineeringProduct gas

A spray dryer apparatus and method suitable for the production of detergents, cleaners and components thereof wherein the inner wall of the drying chamber is provided with an air-permeable textile material lining at a distance from the inner wall, and at least one outlet for compressed gas is provided between the inner wall and the textile material lining whereby adherence of sticky deposits on the inner wall of the drying chamber is avoided or reduced.

Owner:HENKEL KGAA +1

Spray-drying process

The present invention relates to a process for preparing a spray-dried powder comprising (i) anionic detersive surfactant; (ii) from 0 wt % to 10 wt % zeolite builder; (iii) from 0 wt % to 10 wt % phosphate builder; and (iv) optionally from 0 wt % to 15 wt % silicate salt; wherein the process comprises the steps of: (a) forming an alkaline slurry in a mixer, the slurry comprising: (v) from 0 wt % to 15 wt % anionic detersive surfactant; (vi) from 0 wt % to 35 wt % water; and (b) transferring the alkaline slurry from the mixer through at least one pump to a spray pressure nozzle; (c) contacting an acid anionic detersive surfactant precursor to the alkaline slurry after the mixer and before the spray pressure nozzle to form a mixture; (d) spraying the mixture through the spray pressure nozzle into a spray-drying tower; (e) spray-drying the mixture to form a spray-dried powder; and (f) optionally, contacting an alkalinity source with the alkaline slurry and / or the acid anionic detersive surfactant precursor, and / or the mixture.

Owner:THE PROCTER & GAMBLE COMPANY

Processes for the preparation of low dust, limited particle size distribution, surfactant granules

InactiveUS6881359B2High dissolution rateDrying using combination processesSurface-active detergent compositionsDesiccantSURFACTANT BLEND

Processes for preparing surfactant granules, wherein the processes comprise: (a) passing a water-containing surfactant preparation through a casting plate, wherein the casting plate vibrates, such that droplets of the preparation are formed; and (b) contacting the droplets with a gaseous drying agent; are described.

Owner:COGNIS DEUT GMBH & CO KG

Encapsulates

Owner:PROCTER & GAMBLE INTERNATIONAL OPERATIONS SA

Detergent particles

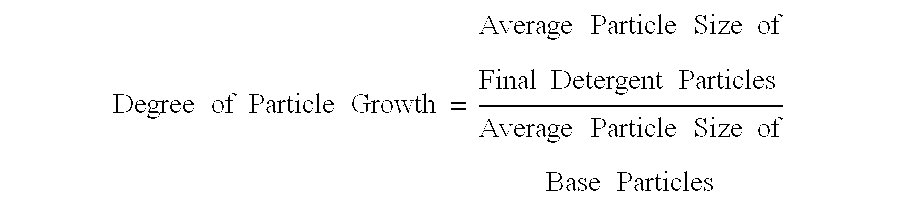

InactiveUS20050256023A1Organic detergent compounding agentsDetergent preparation by chemical meansActive agentPhysical chemistry

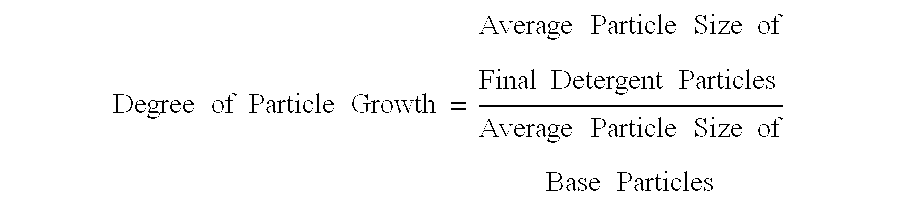

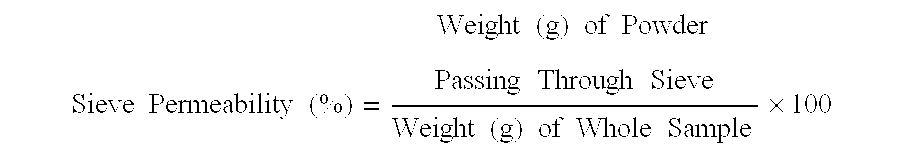

Detergent particles obtained by a process comprising the step of dryneutralizing base particles comprising a water-soluble solid alkali inorganic substance (A) with a liquid acid precursor (B) of a non-soap anionic surfactant, wherein the base particles are obtained by a spray-drying method, and wherein the base particles contain the component (A) in an amount of equal to or greater than 4 times the amount equivalent for neutralizing the component (B) and have an average particle size of from 150 to 400 μm; base particles having an average particle size of from 150 to 400 μm, comprising 20 to 80% by weight of a water-soluble solid alkali inorganic substance; a process for preparing detergent particles comprising the steps of (a) preparing a slurry comprising a water-soluble solid alkali inorganic substance (A) in an amount equal to or greater than 4 times the amount equivalent for neutralizing a liquid acid precursor (B) of a non-soap anionic surfactant to be added in step (c); (b) spray-drying the slurry obtained in step (a) to give base particles; and (c) mixing the liquid acid precursor (B) with the base particles obtained in step (b) and dry-neutralizing the resulting mixture; and a detergent composition comprising the detergent particles as defined above. The detergent particles can be used for laundry detergents, dishwashing detergents and the like.

Owner:KAO CORP

Detergent particles

InactiveUS20050101503A1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSlurryCaking

The present invention relates to a method for making a laundry detergent particle comprising from 10 to 60 wt % (anhydrous basis) zeolite, from 12 to 75 wt % polycarboxylate polymer, and optional additional ingredients to 100% by weight, said method comprising preparing an aqueous slurry comprising zeolite, and polycarboxylate polymer and optional additional ingredients and spray drying the slurry. The weight ratio of zeolite (anhydrous basis) to polycarboxylate polymer in the slurry is from 4:1 to 1:2. The particles have been found to reduce caking of detergent product whilst providing improved cleaning compared with the addition of the polycarboxylate polymer as a separate granule. The invention also includes detergent compositions comprising such particles. The particles may be incorporated into a finished detergent composition as part of an agglomerate or extrudate.

Owner:THE PROCTER & GAMBLE COMPANY

Low Built, Anionic Detersive Surfactant-Containing Spray-Dried Powder that Additionally Comprises Clay

InactiveUS20090325844A1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPhosphateLotion

Owner:THE PROCTER & GAMBLE COMPANY

Solid laundry detergent composition comprising anionic detersive surfactant and calcium-augmented technology

InactiveUS7910533B2Inorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsParticulatesLotion

The present invention relates to a solid laundry detergent composition in particulate form, comprising: (a) anionic detersive surfactant; (b) a calcium-augmented technology; (c) from 0% to less than 5%, by weight of the composition, of zeolite builder; (d) from 0% to less than 5%, by weight of the composition, of phosphate builder and (e) optionally, from 0% to less than 5%, by weight of the composition, of silicate salt.

Owner:PROCTER & GAMBLE CO

Detergent composition

InactiveUS7465701B2Speed up the processReduce liquid viscosityOrganic detergent compounding agentsDrying soapPendant groupPolymer chemistry

A detergent auxiliary composition comprising from 0.001 wt % to 99 wt % cleaning polymer having a hydrophilic backbone and at least one hydrophobic pendant group, and an adjunct ingredient in which the hydrophilic backbone constitutes less than 50%, preferably less than 45% by weight of the polymer. The detergent auxiliary composition may be, for example a spray-dried particle or an agglomerate. Also described are detergent compositions comprising the detergent auxiliary composition.

Owner:PROCTER & GAMBLE CO

Detergent Composition

InactiveUS20110257066A1Good physical propertiesImprove drying efficiencyInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSlurrySpray drying

Preparation of solid free flowing detergent composition by spray drying a chemically simple slurry as well as compositions comprising chemically simple spray dried particles

Owner:THE PROCTER & GAMBLE COMPANY

Detergent compositions

InactiveUS6936577B2Extension of timeLarge particle sizeInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsParticulatesDissolution

A particulate laundry detergent composition which comprises a detergent base powder comprising surfactant and builder and, as separate particulate components:(a) an alkali metal carbonate salt selected from carbonate, bicarbonate, sesquicarbonate and combinations thereof; and(b) a water-soluble organic acid which, when reacted with (a) in the presence of water, generates carbon dioxide gas;wherein the alkali metal carbonate salt, when taken separately, has a 90% dissolution time of less than 15 seconds, preferably less than 10 seconds, more preferably less than 7 seconds; and the water-soluble organic acid has a d50 particle size which is in the range of from 150 to 1500 microns. The alkali metal carbonate salt preferably has an average bulk density of at most 1000 g / l, preferably at most 800 g / l, more preferably at most 600 g / l. The alkali metal carbonate salt preferably has a d50 particle size of at most 250 microns, preferably from 1 to 200 microns, more preferably from 10 to 150 microns. The alkali metal carbonate salt is preferably sodium and / or potassium carbonate.

Owner:HENKEL IP & HOLDING GMBH

Method of making granular detergent compositions comprising amphiphilic graft copolymers

InactiveUS20110152160A1Organic detergent compounding agentsDetergent materialsOrganic chemistryCopolymer

A process of making a granular detergent composition comprising amphiphilic graft copolymer. The granular detergent composition may have an L-3b value of at least about 73.5.

Owner:THE PROCTER & GAMBLE COMPANY

Absorptive particles

InactiveUS20080293609A1Good effectAchieve effectInorganic/elemental detergent compounding agentsNon-surface-active detergent compositionsChemistry

Owner:HENKEL KGAA

Spray-Drying Process

InactiveUS20110147962A1Surface-active detergent compositionsDetergent preparation by chemical meansSpray nozzleSlurry

A process for preparing a spray-dried detergent powder having (i) detersive surfactant; and (ii) other detergent ingredients; wherein the process comprises the steps of: (a) forming an aqueous detergent slurry in a mixer; (b) transferring the aqueous detergent slurry from the mixer through at least one pump to a spray nozzle; (c) contacting alkoxylated anionic detersive surfactant and / or acid precursor thereof to the aqueous detergent slurry after the mixer and before the spray nozzle to form a mixture; (d) spraying the mixture through the spray nozzle into a spray-drying tower; and (e) spray-drying the mixture to form a spray-dried powder.

Owner:THE PROCTER & GAMBLE COMPANY

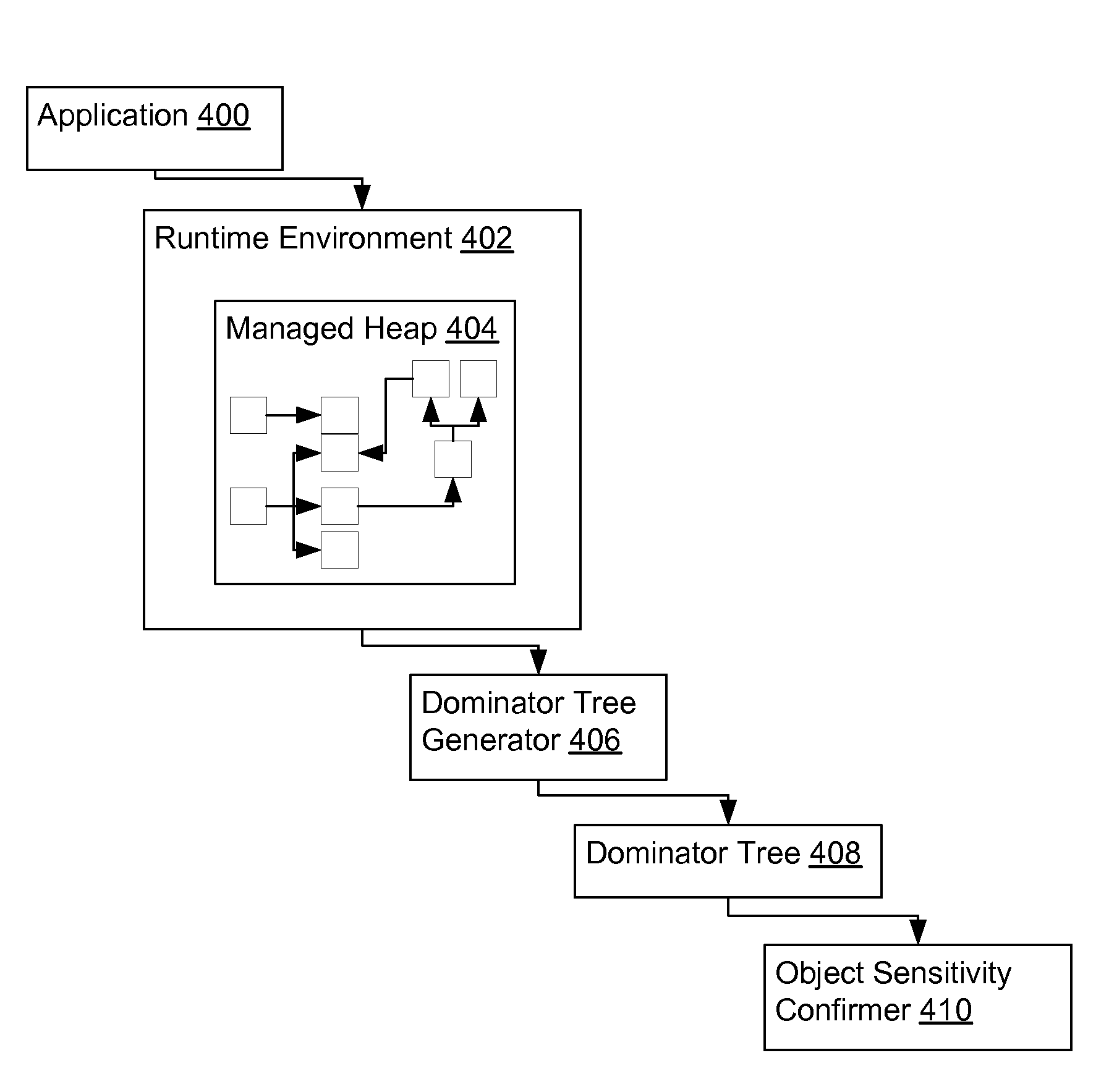

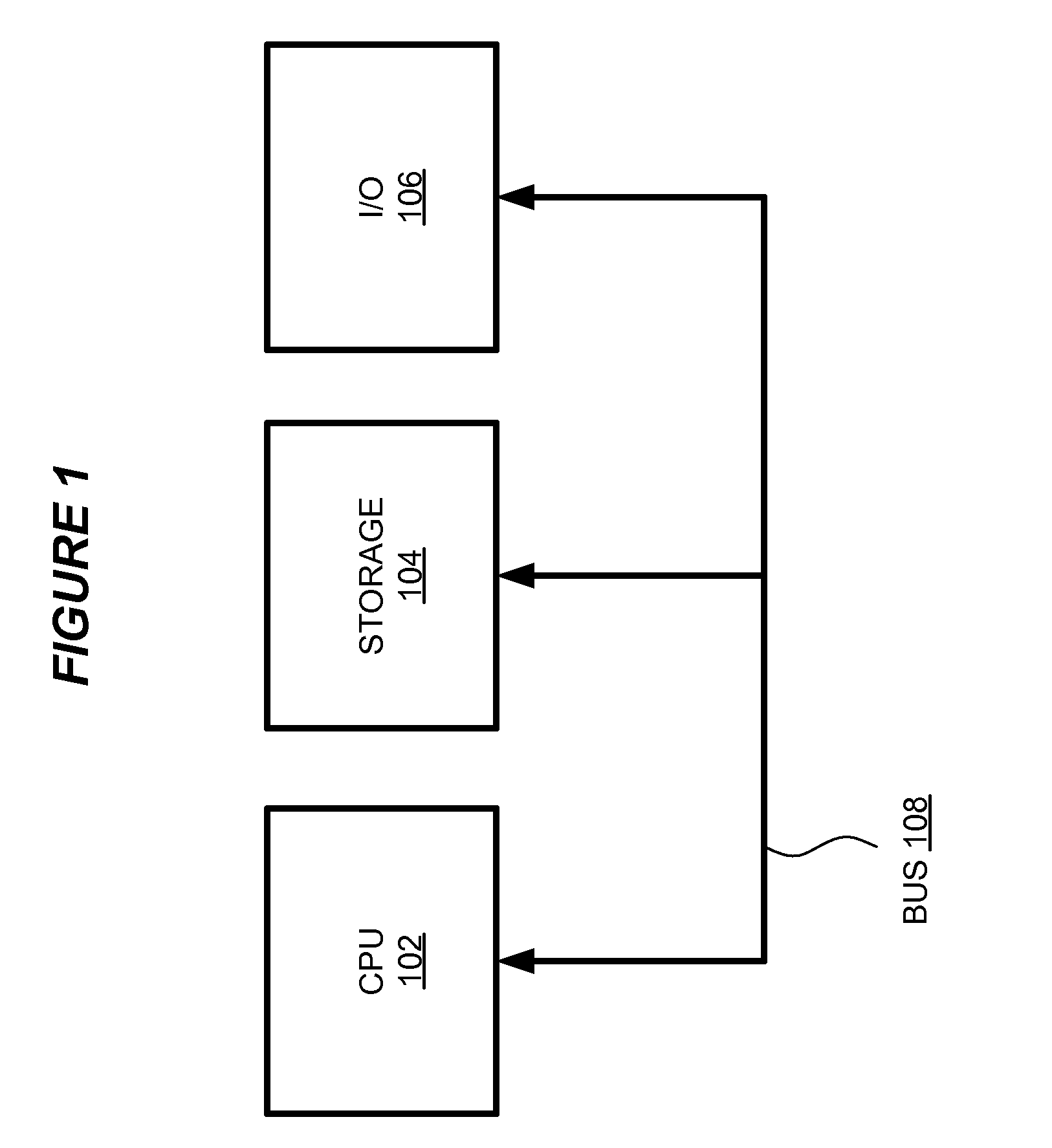

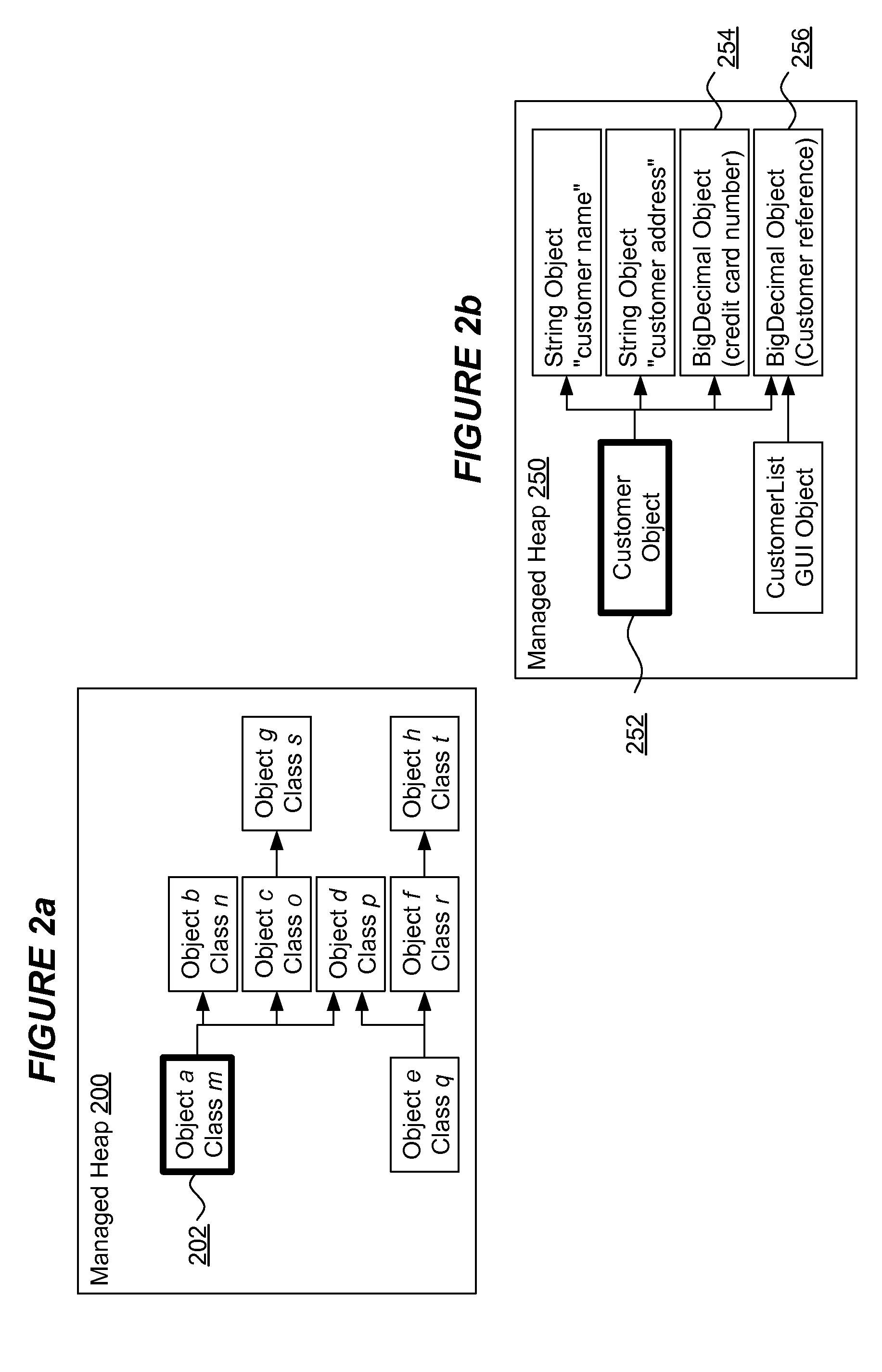

Confirming the sensitivity of a data object in a managed object heap

InactiveUS20110153689A1Surface-active detergent compositionsDetergent preparation by chemical meansManagement objectManaged object

A method, system and computer program product for confirming the sensitivity of a data object in a managed object heap software runtime environment based on a determination that the object is accessible only via other objects known to be sensitive.

Owner:IBM CORP

Process for producing granules for surfactant support

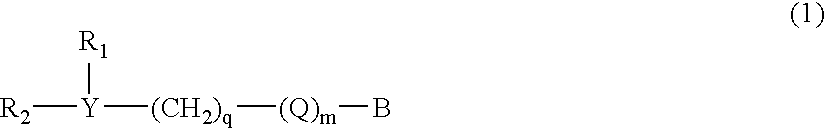

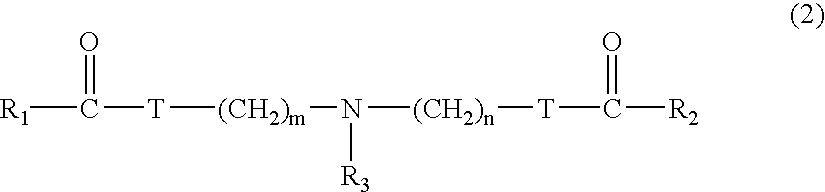

InactiveUS20030004086A1Increase exchange speedImprove support capabilitiesInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsHueOrganic chemistry

To provide particles for supporting a surfactant which are excellent in the supporting ability (supporting capacity / supporting strength) of the liquid surfactant composition and a process for preparing the same; detergent particles prepared by using the particles for supporting a surfactant; and a detergent composition comprising the detergent particles. According to the present invention, there are provided particles for supporting a surfactant having excellent supporting abilities (supporting capacity / supporting strength) of a surfactant composition; detergent particles having high quality and high deterging performance, and further having excellent hue; and a detergent composition comprising the detergent particles.

Owner:KAO CORP

Process for preparing detergent particles

InactiveUS7446085B2Organic detergent compounding agentsDetergent preparation by chemical meansActive agentEngineering

Detergent particles obtained by a process comprising the step of dryneutralizing base particles comprising a water-soluble solid alkali inorganic substance (A) with a liquid acid precursor (B) of a non-soap anionic surfactant, wherein the base particles are obtained by a spray-drying method, and wherein the base particles contain the component (A) in an amount of equal to or greater than 4 times the amount equivalent for neutralizing the component (B) and have an average particle size of from 150 to 400 μm; base particles having an average particle size of from 150 to 400 μm, comprising 20 to 80% by weight of a water-soluble solid alkali inorganic substance; a process for preparing detergent particles comprising the steps of (a) preparing a slurry comprising a water-soluble solid alkali inorganic substance (A) in an amount equal to or greater than 4 times the amount equivalent for neutralizing a liquid acid precursor (B) of a non-soap anionic surfactant to be added in step (c); (b) spray-drying the slurry obtained in step (a) to give base particles; and (c) mixing the liquid acid precursor (B) with the base particles obtained in step (b) and dry-neutralizing the resulting mixture; and a detergent composition comprising the detergent particles as defined above. The detergent particles can be used for laundry detergents, dishwashing detergents and the like.

Owner:KAO CORP

Oil containing starch granules for delivering benefit-additives to a substrate

ActiveUS7279454B2Cationic surface-active compoundsOrganic detergent compounding agentsAdditive ingredientOrganic compound

An oil containing starch granule is provided comprising:(a) a starch to form an effective matrix for said granule;(b) a perfume oil comprising ingredients having a calculated Clog P of at least 3;(c) an effective amount of an organic compound as herein described for inhibiting the migration of said oil to the surface of said starch granule.

Owner:COLGATE PALMOLIVE CO

Spray-Drying Process

ActiveUS20110146099A1Organic detergent compounding agentsDrying solid materials with heatSpray nozzleSlurry

A process for preparing a spray-dried detergent powder having: (i) detersive surfactant; and (ii) other detergent ingredients; wherein the process includes the steps of: (a) forming an aqueous detergent slurry in a mixer; (b) transferring the aqueous detergent slurry from the mixer to a pipe leading through a first pump and then through a second pump to a spray nozzle; (c) contacting a detergent ingredient to the aqueous detergent slurry in the pipe after the first pump and before the second pump to form a mixture; (d) spraying the mixture through the spray nozzle into a spray-drying tower; and (e) spray-drying the mixture to form a spray-dried powder, wherein the pressure drop between (i) the pressure in the pipe at the outlet of the first pump to (ii) the pressure in the pipe at the inlet to the second pump is less than 8×105 Pa.

Owner:THE PROCTER & GAMBLE COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com