Neutral washing powder and preparation method thereof

A neutral washing powder and active agent technology, applied in the field of daily chemical industry, can solve the problems of difficult dissolution, hand injury, and clothing injury, and achieve the effect of good solubility, high cleaning power, and stain removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention. Unless otherwise specified, the technical means used in the examples are conventional means well known to those skilled in the art, and the raw materials used are all commercially available products.

[0029] The percentage sign "%" involved in the following examples refers to weight percentage unless otherwise specified.

[0030] Embodiment neutral washing powder and preparation thereof

[0031] 1.1 Composition and preparation of neutral washing powder

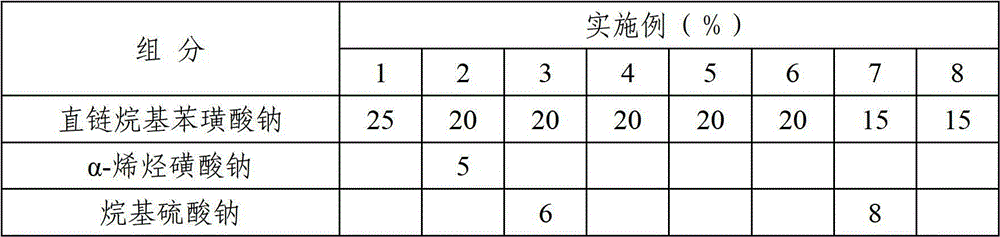

[0032] The formula of table 1 neutral washing powder

[0033]

[0034]

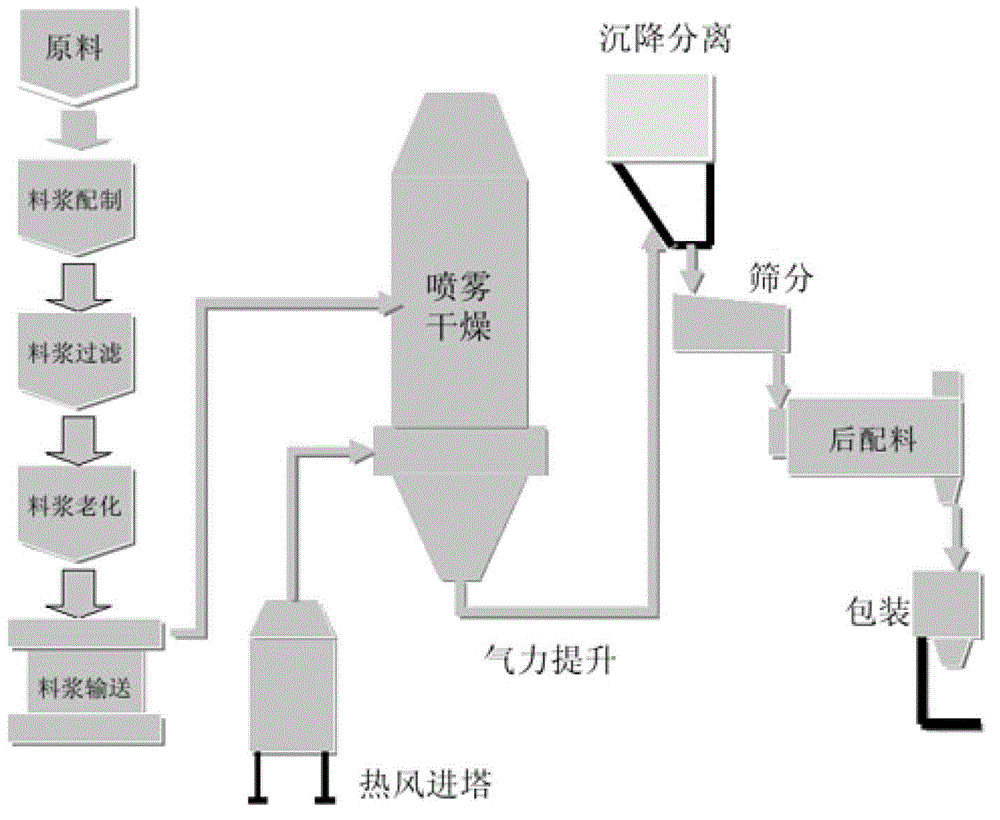

[0035] The preparation method comprises the steps of:

[0036] 1) Add water, anionic surfactant, polycarboxylate, sodium carboxymethyl cellulose, organic acid, sodium p-toluenesulfonate, whitening agent, 4A zeolite and sodium sulfate in sequence in proportion, and mix to make 60% For slurry with ~75% soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com