Novel and efficient electrostatic pre-coalescence method and device applied to dehydration and desalt of crude oil

A crude oil dehydration and crude oil technology, which is applied in the direction of electric/magnetic dehydration/demulsification, liquid separation by electricity, etc., can solve the problem of low gas content adaptability of W/O type crude oil emulsion, failure to use small water particles in dispersed phase Coalescing demulsification mechanism, difficult to deal with high viscosity crude oil emulsion and other problems, to achieve the effect of complete coalescence growth, reducing gravity settling time, improving stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further detailed description will be given below in conjunction with the accompanying drawings.

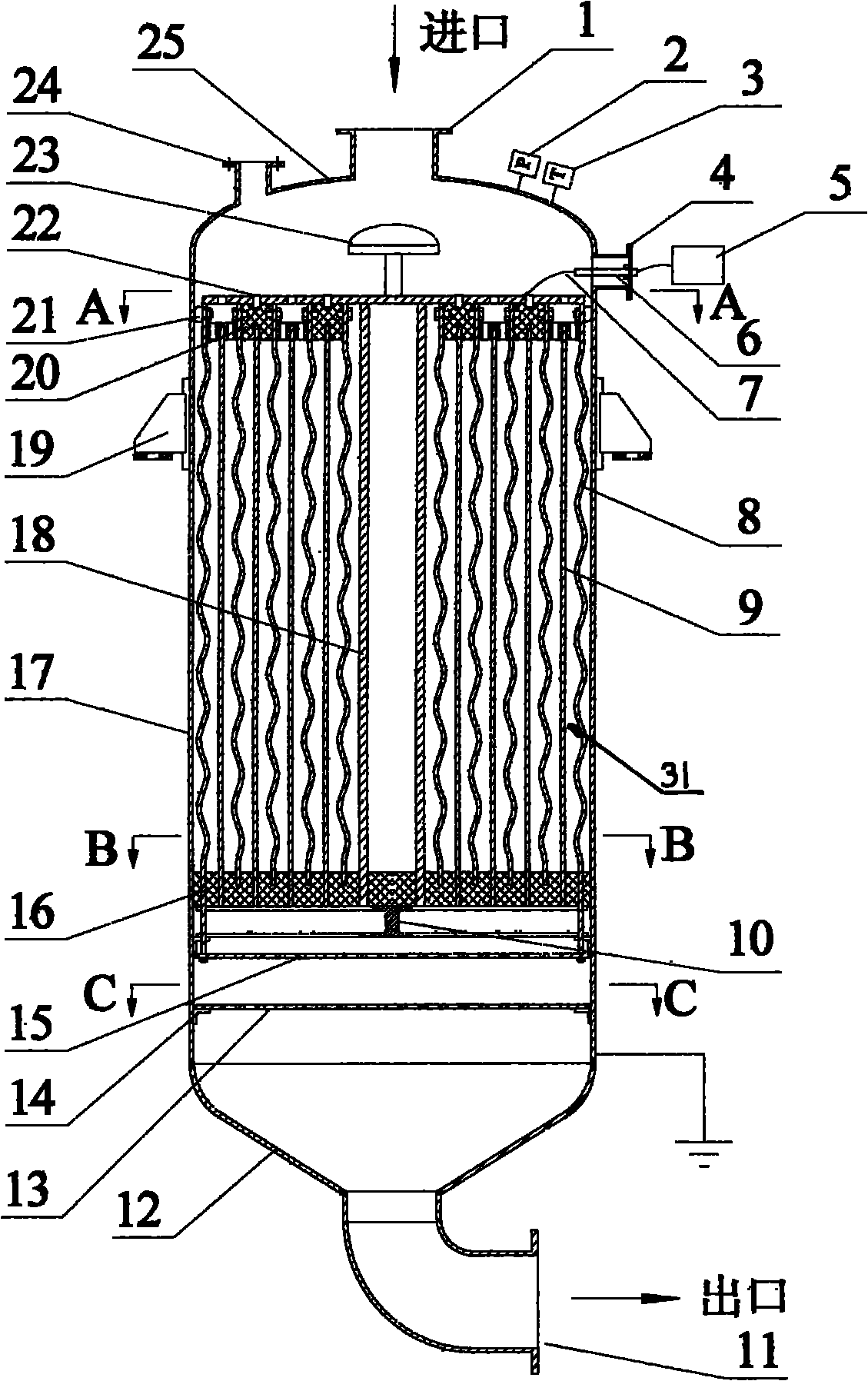

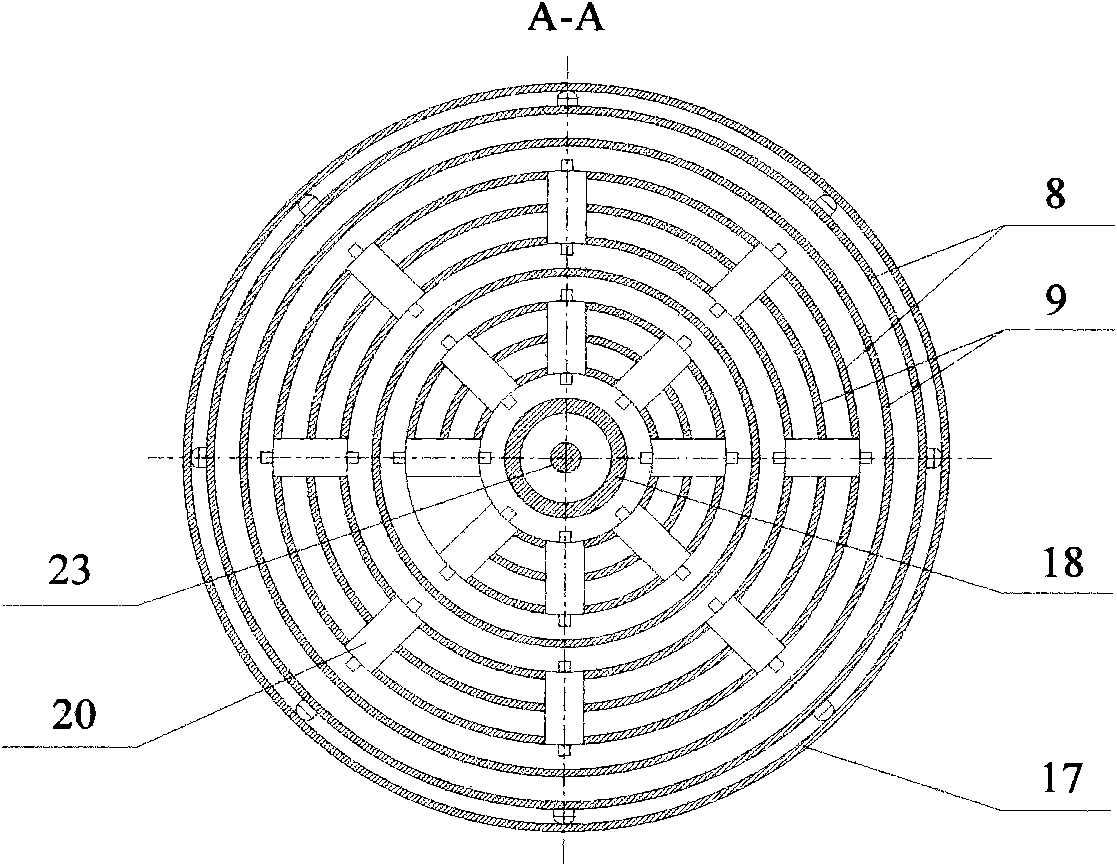

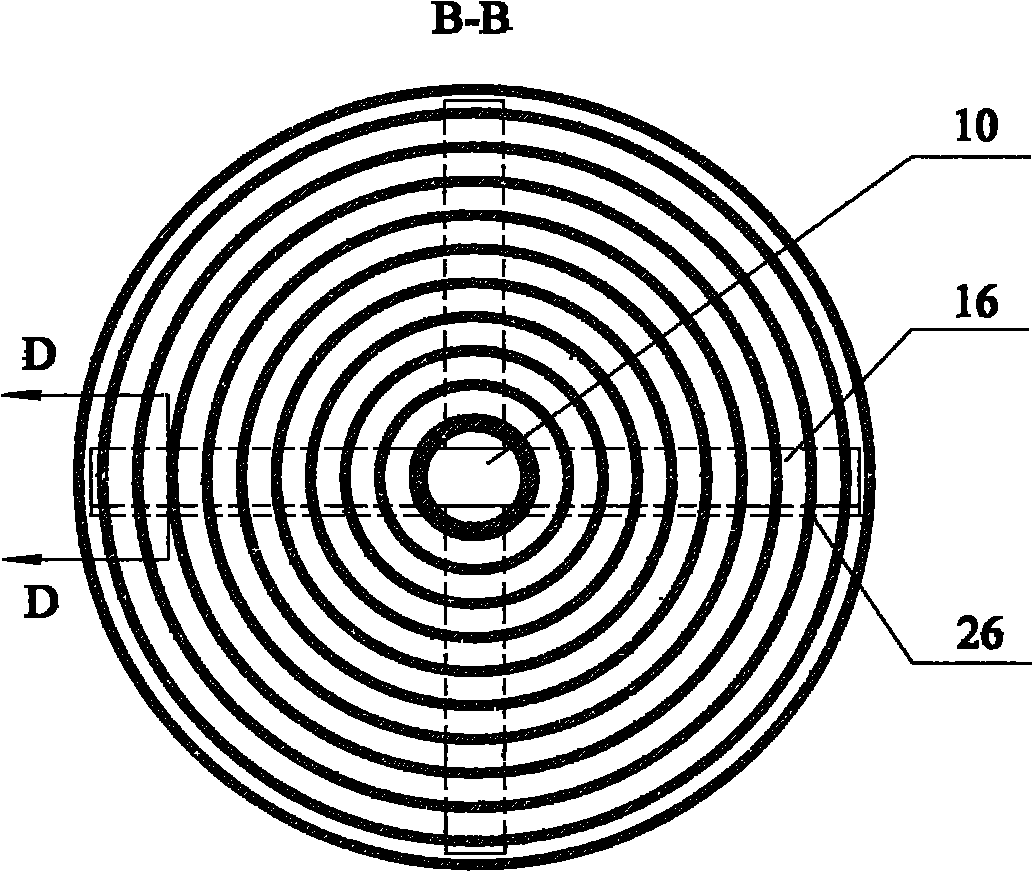

[0023] Depend on figure 1 Show the equipment of the present invention, mainly be made up of elliptical sealing head (25), shell (17), conical sealing head (12), electrode assembly and high-voltage AC power supply (5), wherein: elliptic sealing head (25 ) is installed with an inlet pipe (1) and an exhaust port (24); a pressure gauge (2) and a thermometer (3) are installed on the shell (17), and an electrode assembly is installed inside; Outlet pipe (11). The elliptical head (25) and the shell (17) are connected by bolts, which makes the maintenance and inspection of the electrode assembly more convenient; ) to support the vertical installation of the electrostatic pre-coalescer. The external high-voltage AC power supply (5) is connected with the electrode assembly inside the casing (17) through a high-voltage cable (7). The high-voltage cable (7) is covered inside the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com