Dust control system

A technology for controlling systems and dust, applied in the direction of vacuum cleaners, applications, cleaning machinery, etc., can solve problems such as not being completely effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

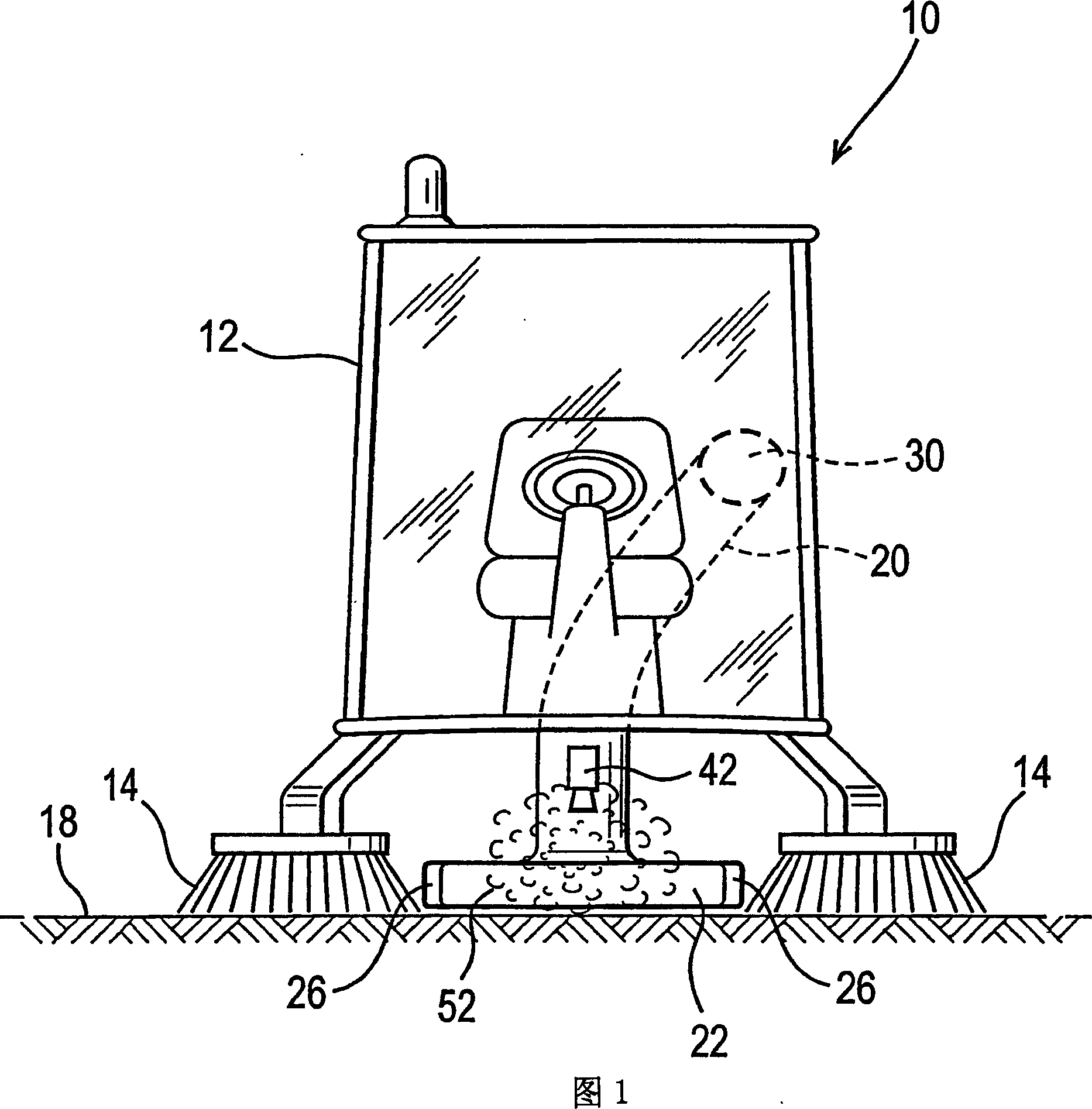

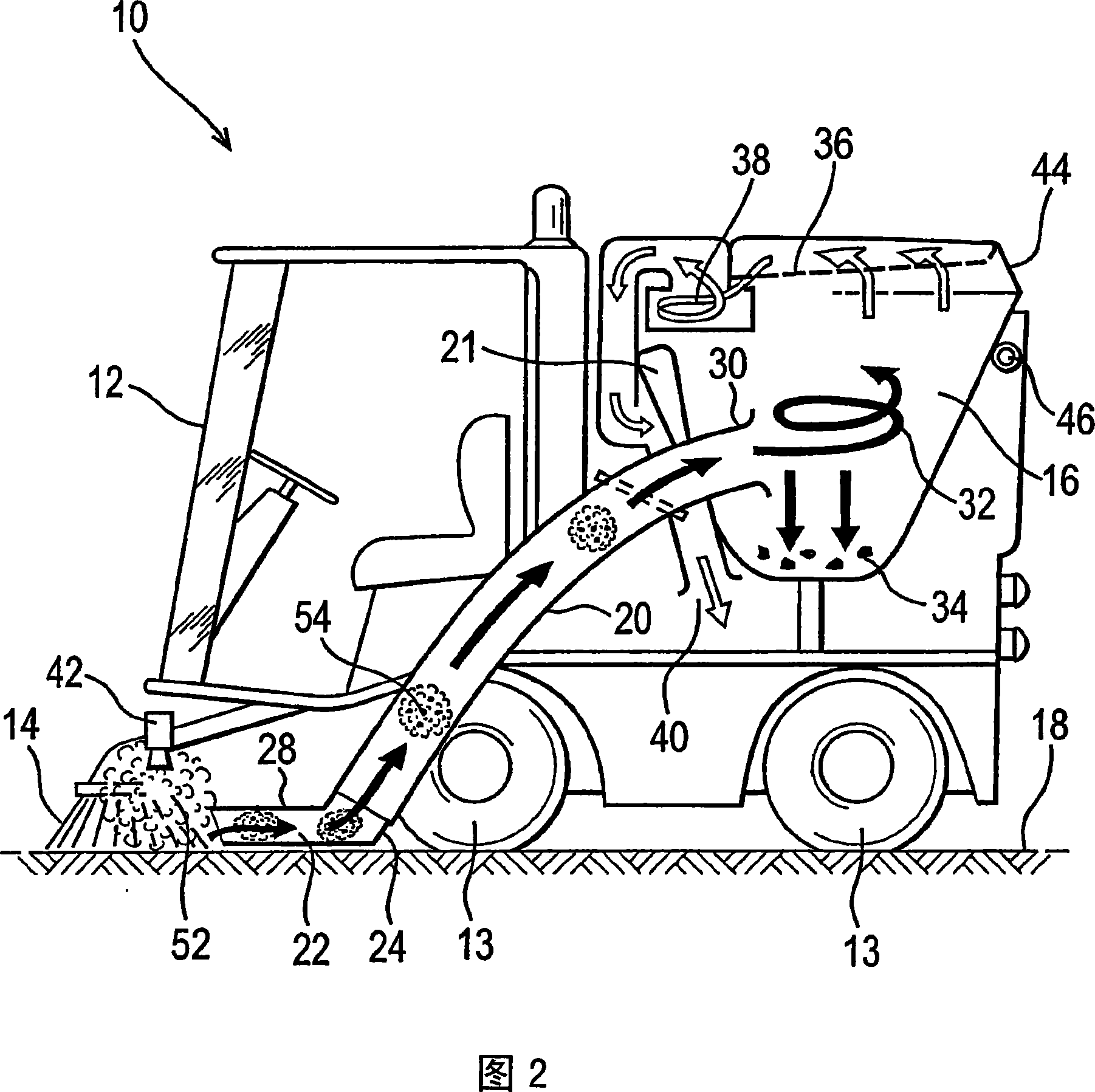

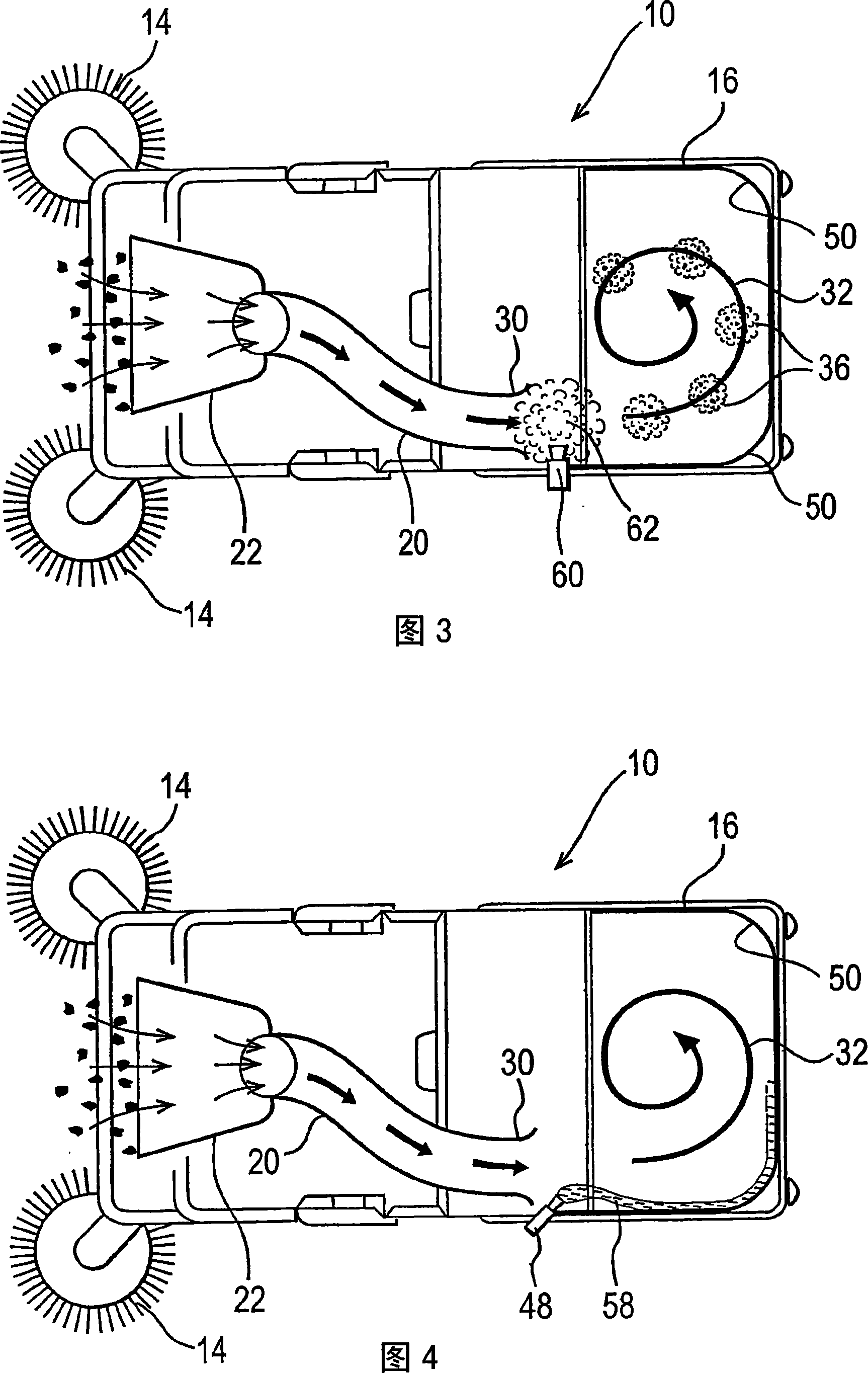

[0070] The present invention provides a road cleaning machine or road sweeping machine (10) fitted with a dust control system using water atomizers (42, 60). Atomizers (42, 60) are fine units for generating water droplets of similar size to dust and enter the dust handling system of the road sweeping machine by entraining the atomized water, e.g. from a brush (14) through a straw (20) Into the hopper (16), dust control is established.

[0071] The illustrated road sweeping machine (10) includes a cab (12), four wheels (13) - two shown, two counter-rotating brushes (14), a bucket (16) (see Figures 2 and 3) ) and a straw (20). The cab (12) is located in front of the machine (10). To sweep dirt off the ground (18), two counter-rotating brushes (14) are located under the cab (12) and slightly forward. The bucket (16) is used to collect dirt and debris off the ground (18). The suction pipe (20) is driven by the blower (21) (see Fig. 2) for sucking up the dirt from the floor (18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com