Quantitative evaluation system and method of crude oil emulsion stability

A quantitative evaluation and emulsion technology, applied in the field of quantitative evaluation system of crude oil emulsion stability, can solve the problems of unfavorable reading, insufficient representativeness of water droplet size distribution results, complicated operation, etc., and achieve the effect of convenient and quick use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

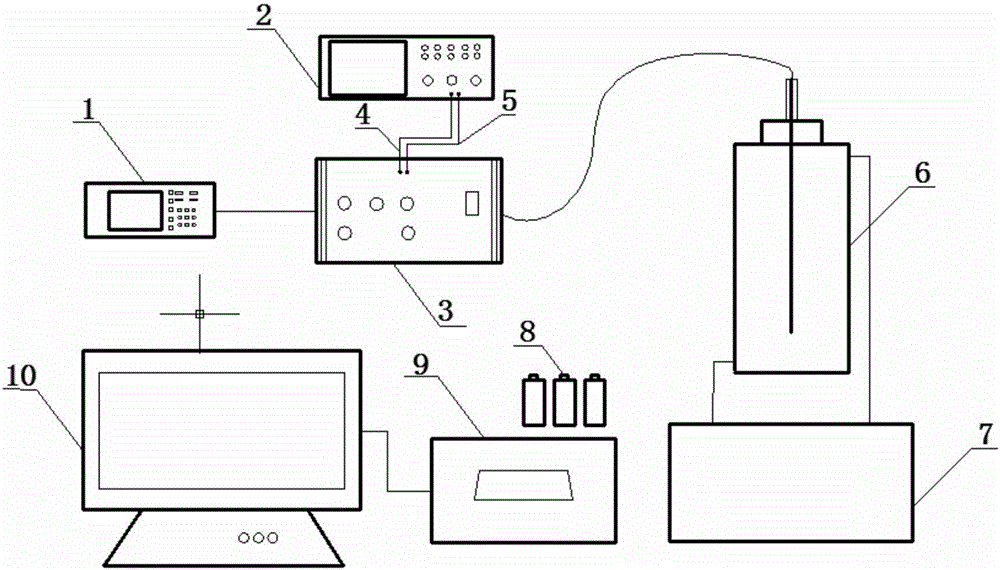

[0027] The quantitative evaluation system of crude oil emulsion stability of the present invention, its preferred embodiment is:

[0028] Including signal generator, oscilloscope, voltage amplifier, bottle test demulsifier, constant temperature water bath, emulsion test bottle, dynamic stability analyzer, computer, etc.;

[0029]Electric field demulsification or chemical demulsification by the above systems:

[0030] The electric field demulsification includes: the signal generator generates electrical signals with specific waveforms, voltage values and frequencies, and after the signal is amplified by a voltage amplifier, a non-uniform high-strength The electric field makes the water particles in it electrostatically coalesce, and then accelerates the gravity sedimentation;

[0031] The chemical demulsification includes: directly adding a demulsifier to the crude oil emulsion in the bottle test type demulsification dehydrator for chemical demulsification without applying a...

specific Embodiment

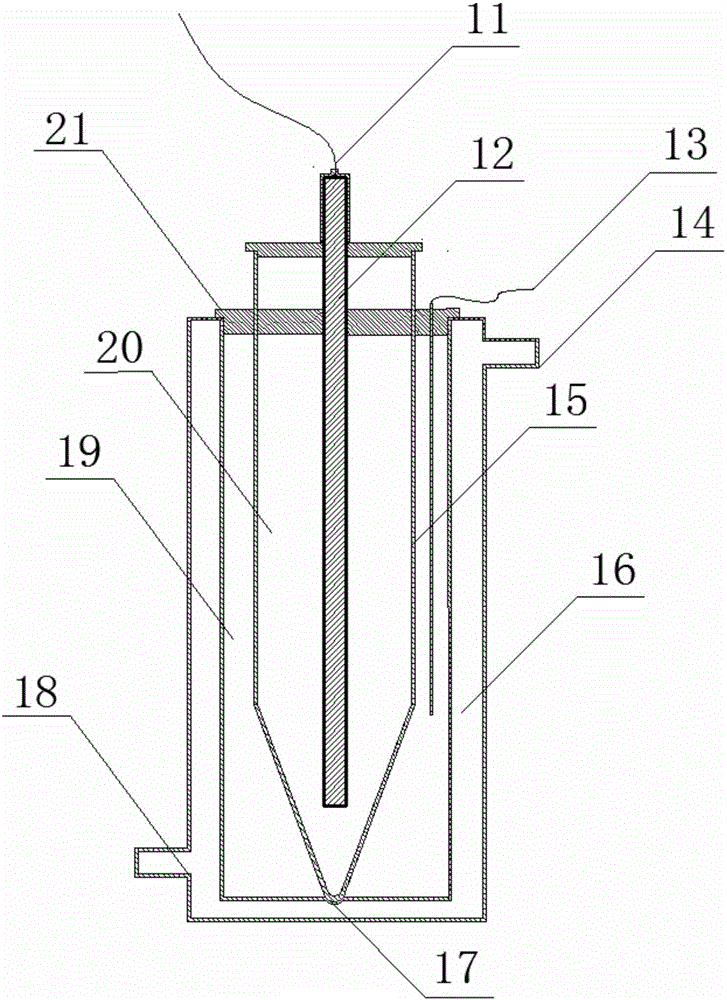

[0059] Such as figure 1 , figure 2 , image 3As shown, the quantitative evaluation system for the stability of crude oil emulsion consists of a signal generator (1), an oscilloscope (2), a voltage amplifier (3), a bottle test demulsifier (6), a constant temperature water bath (7), an emulsifying A liquid test bottle (8), a dynamic stability analyzer (9), a computer (10), etc., a signal generator (1), an oscilloscope (2), and a voltage amplifier (3) together constitute a high-voltage power supply and monitoring device. The bottle test type demulsifier (6) is generally a vertical structural layout of three cylinders coaxial with the center line. The innermost cone-bottomed measuring cylinder (15) is filled with the crude oil emulsion (20) to be tested. The middle annular space between the measuring cylinder (15) and the middle cylinder is filled with electrolyte solution (19), and the outer annular space between the middle cylinder and the cylindrical outer cylinder is filled...

Embodiment 1

[0061] Example 1: Evaluate the influence of different electric field parameters on the stability of crude oil emulsion.

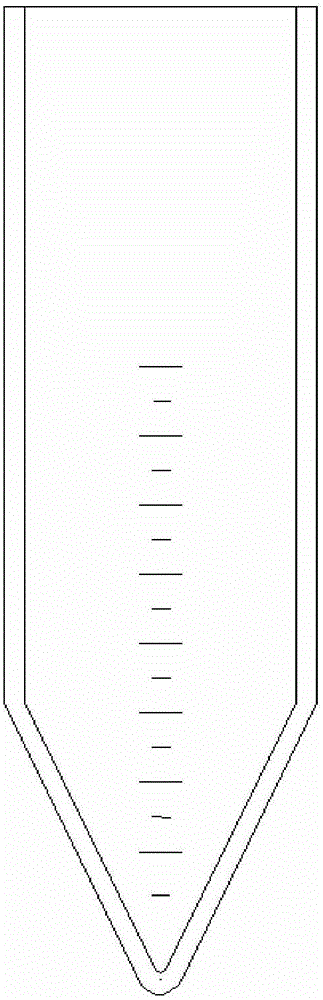

[0062] 1. Pour the prepared same batch of crude oil emulsion (about 50ml) into the cone-bottom measuring cylinder (15) of the bottle test electrostatic coalescer (6), and rise to the set demulsification temperature under the action of a circulating water bath; then Turn on the high-voltage power supply and monitoring device, apply a high-intensity non-uniform electric field to the crude oil emulsion (20) in the cone-bottom measuring cylinder (15), so that the dispersed phase water particles in the crude oil emulsion (20) undergo electrostatic coalescence. After continuous power supply for about 1min, turn off the high-voltage power supply and monitoring device. Put the crude oil emulsion after the demulsification into rest for a period of time, and the detached water will settle at the bottom of the cone-bottomed measuring cylinder (15). Since the cone-bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com