Coating device comprising a jet of coating medium which is broken down into drops

A coating device and a coating agent technology are applied to the coating device, especially the application equipment, and the corresponding coating field of discharging droplet type coating agent jets, which can solve expensive operation costs, high investment costs, and high environmental loads. or threats and other issues to achieve the effect of saving paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

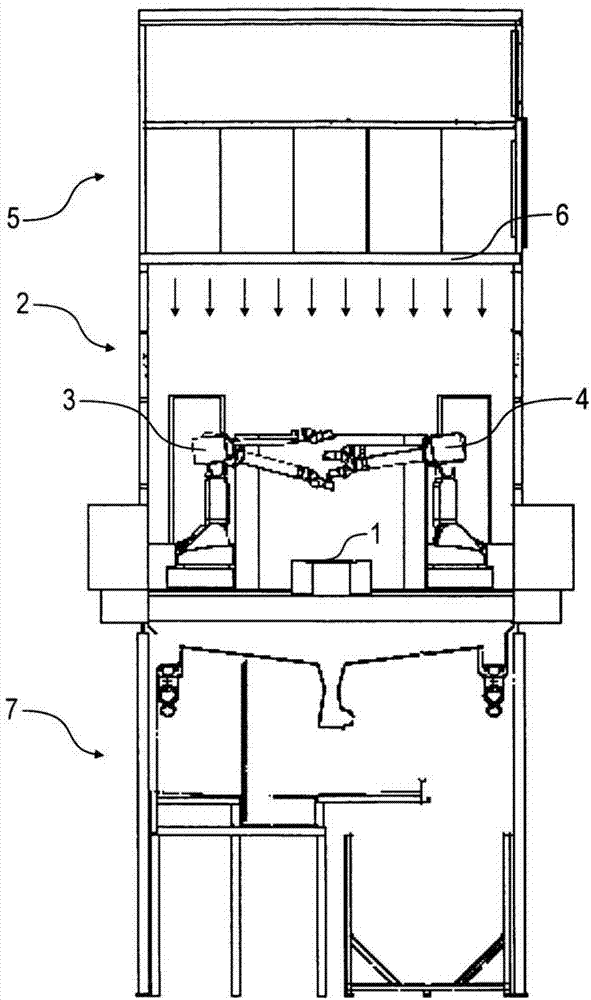

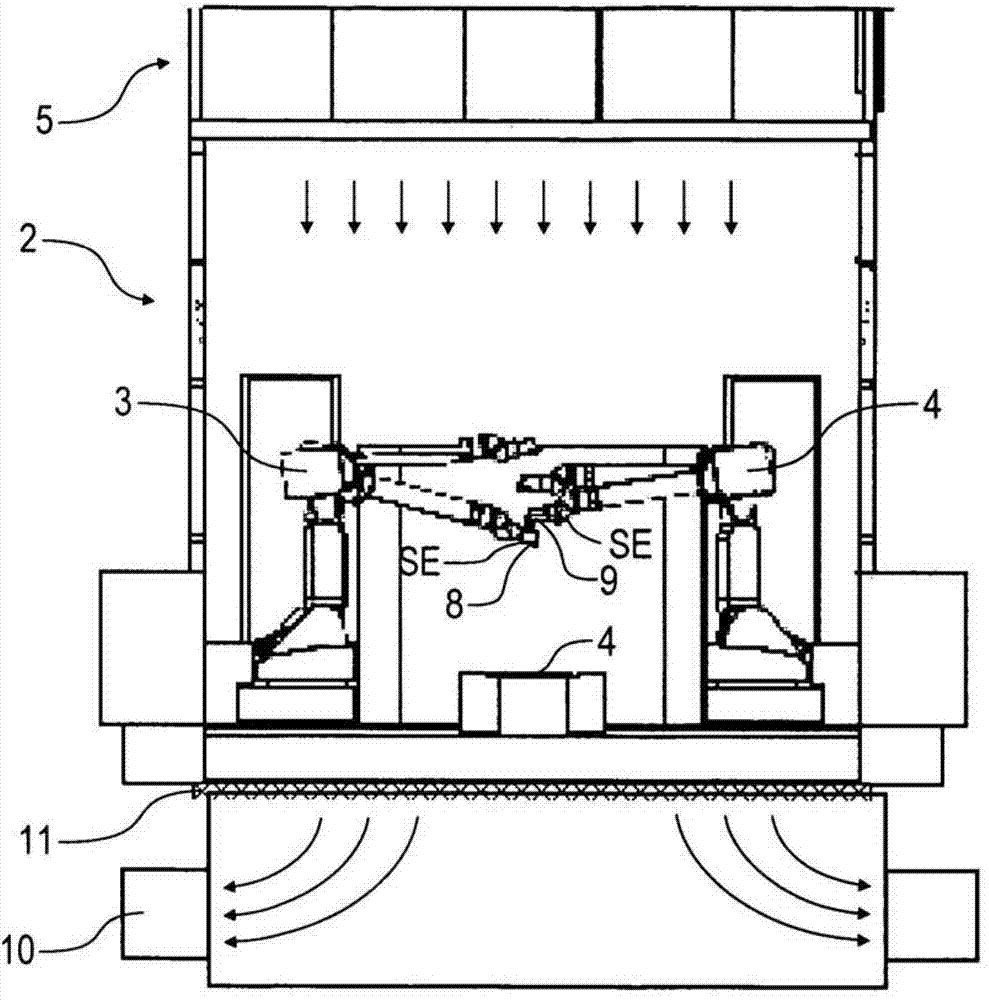

[0117] figure 2 The cross-sectional view in FIG. 1 shows a painting installation according to the invention, which partly corresponds to the conventional painting installation shown in FIG. 1 , so to avoid repetition, reference is made to the above description, wherein the same reference numerals are used for corresponding details.

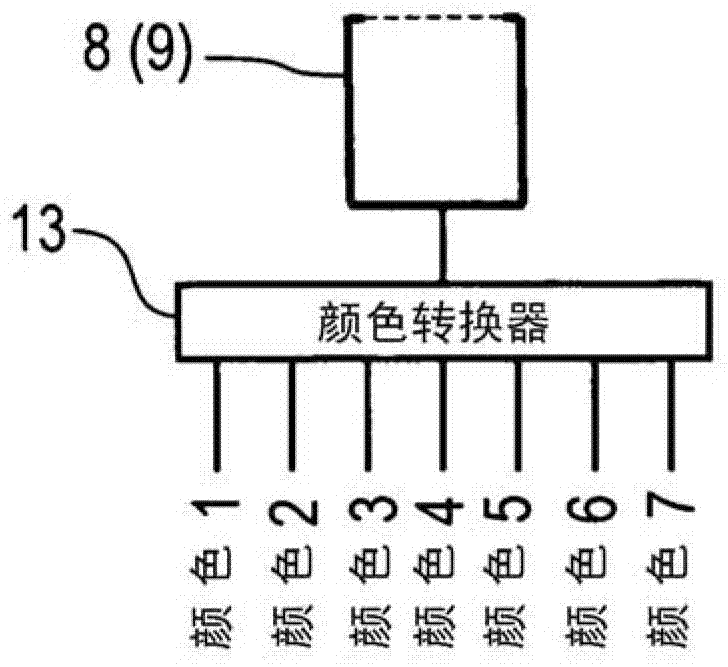

[0118] The specific features of the painting installation according to the invention initially consist of the fact that the painting robots 3, 4 do not use rotary atomizers as application means but use application devices 8, 9, each of which comprises an oscillation generator SE and can be called be the droplet generator or applicator head. Each application device 8, 9 has a higher application efficiency, which is more than 90% higher than that of a rotary atomizer. In this way, less overspray is likely to occur because the application devices 8, 9 are capable of forming coating agent droplets, in particular paint droplets, with substantially the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com